Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,605 -

Joined

-

Last visited

-

Days Won

98

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Everything posted by Bushwacked

-

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

Got sidetracked with the holidays and #2020, we went ahead and put up christmas stuff already ? Here everything is, it is finished ... Aprons on and glued up The biggest gap I had in all 4, I am pretty happy with that. I burnished it (I thihnk is the term) with a screw drivers length part (not sure what to call that .. the circle part not the tip) to round of an mesh everything together and could not tell after that. 2 coats of stain, went with the provincial stain for GF. Also, sand the legs lightly, and cleaned off with degreaser. Then painted with some canned spray paint from HD. I can find the brand if needed. Installed in its place ... definitely a talking piece now haha. Now one of these years we will get rid of all the hand me down couches that the kids are slowly destroying and it will look/match a lot better in the room. As for the whoopsy, I didnt have time to actually correct it as the wife wanted this completed. So I stuck with the domino patch and with the darker stain, you really cant see it unless you look. So it worked out pretty well. I was going to rip it out and redo, but I had orders stating otherwise ? Finished dimensions ended up being 41 1/2 x 41 1/2 x 15" Here is a couple quick shots of it .. you really cant see it unless you get as close as I did to take the pictures. You can also see the ~1/32 - 1/16" gap around as well ... -

I brought this up awhile back on the old forums, but it did not make the cut over here ? I am curious what you all are using in between finish coats. I am not sure what are good sponges to use that all my cans recommend. I normally have just been hand sanding with 320 to 400 grit paper between coats, which I am assuming there is a better way ... wanted to get yalls thoughts on it.

-

going to need to get a tax ID number then somehow ? Then I can claim a company vehicle too when I purchase a new one

-

PPE for finishing. Spraying mostly

Bushwacked replied to Bushwacked's topic in Finishing Discussions

man that few hours, even with your 15-20? I am assuming people wearing a mask with P100's on them for dust are not changing their filters every other day if they are putting 6-8 days in. If this is the case, I need to change out mine too ? haha. That gets expensive. Haha! If the refinery people are anything like the roughnecks ... not a shit was given. I am all for learning, as this topic is somewhat new to me ... I know the basics, wear a mask, dont breath this crap in try to wear a mask as much as possible to protect your lungs. Although, gotta say, while I am cutting things on the tablesaw or mitersaw or really any of the big tools, I dont wear a mask. Now if I am cutting MDF, I will wear a mask as much as I remember to as that is nasty stuff. -

this!! Love mine, but damn if it doesnt drive me crazy getting it set back up for use after some time away from it.

-

PPE for finishing. Spraying mostly

Bushwacked replied to Bushwacked's topic in Finishing Discussions

Amazing reply/info Kev!! Appreciate the thoroughness of it!! I haven’t actually stored my current mask in a sealed bag ... just normally blow it out when I’m ready to use it. although it brings up a couple other questions .. 1) how do you know when your filters actually need to be replaced? 2) how many people do they actually catch with using the sealing bags? -

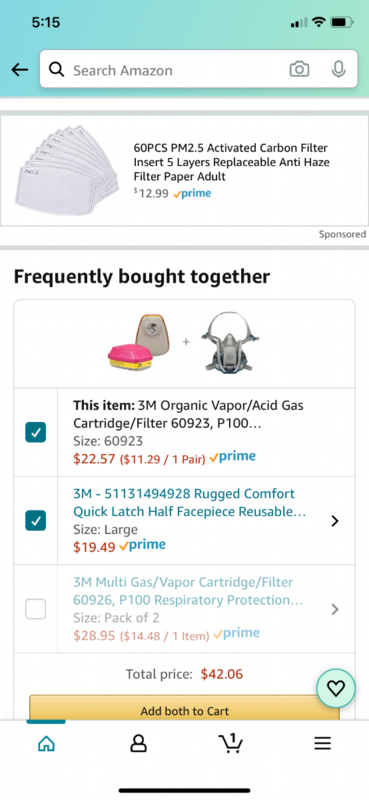

I am curious what y’all use while spraying finishes ... I need something, but not 100% sure what. I was thinking this mask/filter combo??

-

where did you store the build cabinets? I was thinking this would be my route, but free space is not that great so I would need to store somewhere in the house I guess until I get everything built and could rip out the old.

-

Very wise words there ? ... going to have to remember that.

-

amazing work!! Corian is way better than the tile tops before ? 51 days eh? Thats quite the effort getting all this done. My wife has a redo of the kitchen cabinets on her list too! I will show her this and let her know this was 51 days and no big issues ... great way to level set its not a week project ?

-

I dont have the red/black valve on mine ... is that an add on?

-

yes, hopefully they honor it and dont claim a whoopsy!

-

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

not sure yet ... had my wifes brother and their kids come up this weekend so I had 0 time in the shop. For now, I have just put in the domino and glued and cut flush. Just wanted to get rid of the hole first .. I will take a look tomorrow and start thinking of what to do next. -

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

gotcha ... then I wont work about it when I get there and just assemble then stain/finish as normal. Appreciate the 2nd opinion Kev! -

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

The bottom of the top, if I dont prefinish, would be left with nothing since it will be screwed down to ply. Then about half of the apron would not be able to get any stain/finish from the ply and up. Is that OK? -

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

So the only reason I am thinking I "should" prefinish is that if I do not, there will be a lot of raw wood left open to absorb moisture and all of that. Am I wrong in thinking that? If I do not have to prefinish and could just install and then 1 last finish sanding and then stain/finish, that would be amazing. -

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

just to prep for finishing ... I am curious on a couple things .. 1) For the top, do I just stain the top and sides, let dry then apply ARS to all of it? (top, bot and sides?) 2) For the aprons, I was going to finish those as well before installing, run a 3/4" piece of tape down the backs where I will install it to the ply, so I can add glue to it. 3) For the ply, Just throwing ARS on it like normal. Once all that is done, then I spray everything with my GF high endurance? Thoughts on that process of finishing this up once it gets ready? -

Having trouble uploading images. Known issue?

Bushwacked replied to RxR Sawdust Station's topic in General Discussion

-

I was debating on getting a 2nd gun .. I have the gravity feed one with mine, and was thinking of getting the bottom feed, whatever that is called. Mainly my thought process was I could really see if one works better than the other, then if they seem to be working about the same, use 1 for oil based things, then the other would be water based. Not sure if that is the logic I should have using these, but it is what I was thinking of at least haha. Now seeing this whip hose, I really may take a look at picking one of those up too. I have noticed in some cases my normal hose gets a little stiff for what I am trying to do or get to.

-

Bushwacked Garage Reno Complete in 2020 sometime ... Hopeful

Bushwacked replied to Chet's topic in Member Project Journals

Think I figured out what I wanted for at least one of the side middle cabinets ... Should hold my Milwaukee drill and its attachments, 6 containers, mainly for screws and then a row of sandpaper boxes. Also, added another shelf in the upper cabinets to help out with storage. Doors will be coming sometime soonish I hope. I think after my coffee table build I will wrap those up. Also, all the doors are now inset, just need pulls on them too. Fancy door stops ? -

When does yours show up? I like how you can add extra feet or whatever they are called. So you could have a dado setup and then like if you have other projects that have a lot of repeatable cuts you could set that up each time too and not lose your dado setting

-

hah! yes I was thinking the same ... it had to of been way more expensive and then was really surprised of the 'low' price tag

-

what a beating!! glad you got everything going again though.

-

This seems like a decent idea for repeatable cuts ... a lot of money to get it setup, but nonetheless I still think it is a solid idea if you are cutting something quite a bit, but also need to move the fence around for other cuts ... https://www.woodpeck.com/rip-flip-fence.html?utm_source=bm23&utm_medium=email&utm_term=Woodpeckers+RIP-FLIP+Fence+Stop+System&utm_content=Only+3-Days+Left+to+Pre-Order+your+RIP-FLIP+Fence+Stop+System.&utm_campaign=11.21.20+Rip-Flip+Fence+Stop+System+R5&_bta_tid=09633242875476421803960484212407071197230545681865512639420057443441963987306585169527100076231891722523&_bta_c=0z3i0axvatzuuwg0x23dfrbvjf2ko

.thumb.jpeg.3f113ecd1166599d79e1d473f8a91d23.jpeg)

.thumb.jpeg.5cf205f2ea9f79dbf7cc798f0f7d1186.jpeg)