Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,605 -

Joined

-

Last visited

-

Days Won

98

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Everything posted by Bushwacked

-

Hah! Gotta love the trade secrets over there of 'not giving out the password' ? ... good to hear you got it worked out! You order it then?

-

looking great!!

-

it is his stepstool is the other one ... Are you talking about this section? If so, I get an error about not being full member when I click on the 'Live Today' link.

-

3) Haha!! No need to bring facts to this discussion ? 4) So I thought through that today as well ... If I go this route with a 3-4" top, it would be too heavy for my casters most likely so I would need to take those off (4" casters) and put some on like yours. Then I have the extra room needed for the big top. Oh did not know that was an option to get in for free. Are these sessions recorded in there so I can go listen?

-

1) Agreed, that would be way too small for a drawer above it. I will have to see about removing the handle and see if I can get some space ... we shall see. 2) gotcha, I will look around 3) dont see myself handplaning anything ... dont even own a basic block plane. Although it is on the list just for small work like chamfers and stuff, but thats about it. 4) thats big ... I am thinking I am going to go MDF/Melamine first. Test it out and install it to where I can always come back and at a thick top if needed. Especially if I get into more hand tool work, but right now DT's is about all I plan on so for the foreseeable future, thats the plan. If I go that route, I can retro fit the top easy enough to accommodate the new top. dang ... curious what his new OF thoughts are. I am not a member of the guild.

-

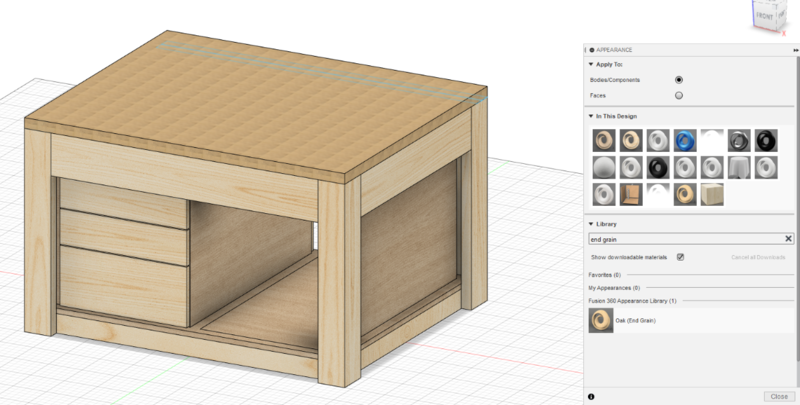

Hah! Yes, this has taken many different variations and looks so far. Mainly a beefy outfeed/assembly table that I can throw a moxon vise onto were the 3 big things. Extra clamping areas to help while assembling was the only reason for the paulk style holes. And for those curious on the hardwood top ... Apparently F360 only has 1 end grain option and that is Oak haha. So for now it is an oak top. Definitely not spending the money for an oak top though.

-

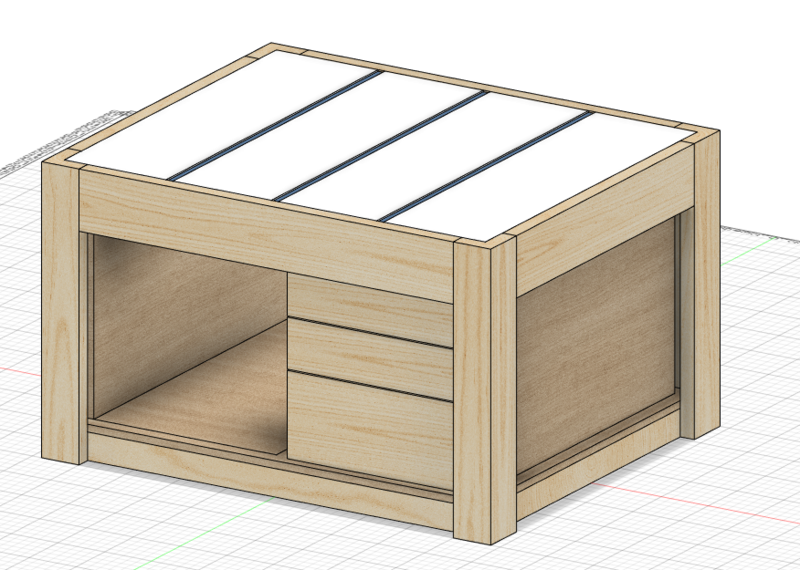

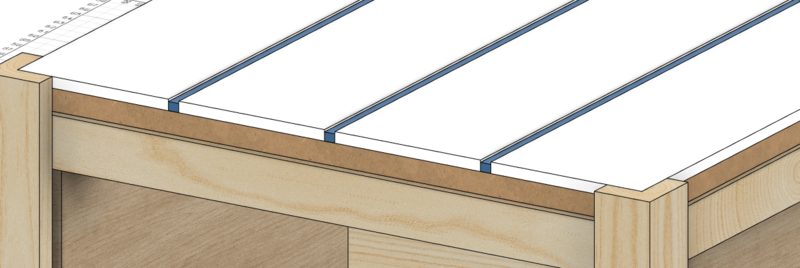

Not sure either ? Just quickly googling I found this from some random person, so take it for what its worth... I picked up Shwartz's workbench design book yesterday and got through the first few chapters. I was surprised to read that holdfasts don't work as well with a really thick top - as I had assumed the thicker the better. I was pleasantly surprised that he also said they are good down to about a 1.25" thick top. I had been planning on a 2" thick top and so I had written off using a holdfast. 1) Right now the height of the opening is 19". The top of the handle on my air compressor puts it right around 17 1/2" so it should be a snug fit. 2) What type of leg vise would you recommend? One like you have on yours? Or something else/cheaper? I will look into and see if my leg sizing would be compatible just in case. 3) agree, more than likely will go with the ones Chet mentioned, as I can use those elsewhere too if needed. The holdfasts are a one trick pony and I dont think I need those just yet. 4/5) Hmmmm, how thick of a top you think it would need to be? With this being on casters it is starting to get pretty heavy with a solid top on it. I will work on drawing something up .. Maybe 8/4 poplar cut into 1 1/2" width pieces, which would probably make it around 1 1/2 x 1 1/2 by the time milling is done. Here is my first take on this layout .. 2 - 3/4 MDF sheets and then 1 Melamine sheet on top with some t track in there. I dont have any high wall space open where the compressor would be able to sit, otherwise that would be a great idea. Glad this top would help me get rid of the paper roller and save a little $$ there.

-

1) Big open area is for air compressor and hopefully moxon vise if they both fit. It gets my compressor safely off the floor and not worried about hitting it with wood. I dont have much open space out of the way to store one, so it sits on the cart for now. 2) The only vise type thing I was thinking of for now is the moxon I was going to build. Is a leg vise able to be added later? 3) did not think of any holdfasts as this isnt necessarily a workbench where I would be hand planing or any of that stuff. I guess they could help with clamping projects down if needed though. However, as you stated, this design is not very conducive for them. Not sure what kinda crazy project they would help me hold still though. 4) Hah! I am in the same boat, not a huge fan, but I put those in the for mainly just giving an area for my clamps to get in and grab to. Maybe with the thickness of my frame I could use that instead and then I would not need the paulk holes? 5) If I did the split top ... would I need to do butcher block top or is that not 100% necessary? Possibly just throw some 2x"X" pine up there and be good? Yes, the vision is outfeed and assembly that can hold a little bigger of projects. I run into the issue of just missing being able to stabilize my project by just a few extra inches quite a bit for some reason ... and then throw my moxon vise on top for when I become a magician with hand cut dovetails ? Hmmm .. I the T Track idea if I go the MDF route. Dont have to worry about anything below, like the cabinets getting in the way then. Love ratchet clamps, they are quickly becoming some of my favorite little go to clamps. Hmmmm ... valid point haha. So if I just go double MDF top, then I should just raise the legs the extra height of the now missing torsion box and maybe add another drawer and just make a deeper drawer?

-

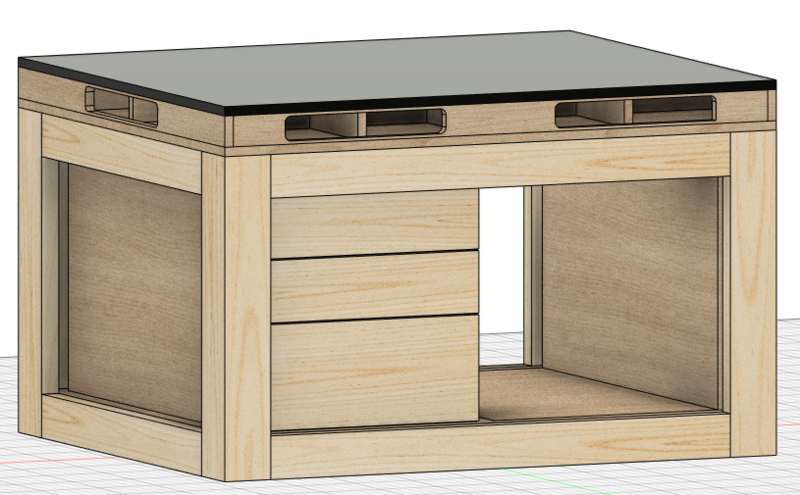

So after building version 1 and using it for a year or so now? I have had enough new thoughts, complaints from it that I built a newer version. The big things I was needing: a slightly bigger top. So this one is going to be 48"x40"x34" (previous was 48x32x34) Drawers, the current one could have them, just never got around to it. This will have 6 drawers holding a lot of my assembly tools needed and my new dovetail things ? clamping areas, this is what the Paulk style holes are for in the side, but a torsion top as well to hopefully achieve a flat'ish top 1 side will have an area to hang a roll of brown craft paper, the other side will hold smaller hand clamps, like the kreg and the dewalt squeeze clamps and all of that. one of the MAJOR things, I needy more beef, so this will be hardwood, most likely Pine structure as it is cheaper. It will be on wheels as well, just dont know how to do wheels in Fusion 360 ? The open space will store my air compressor and maybe the moxon vise that will be coming as well. If not, then some other low use hand tools like my wrench set etc. Trying out a melamine top for slippery outfeed and glue cleanup. Does anyone see any clear issues with something like this? Hoping to get going on this this week maybe.

-

I do my best testing in production too ?

-

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

I was thinking the same with this one when I did it ... now I either sanded amazingly well and got all the glue off of where it did not belong, or the darker stain helped cover it up? Either way, I looked for signs and could not see anything on the corners. Going forward though I will definitely be using the CA glue trick as like Kev mentioned, the dry time is so much better. -

Dovetail tools ... down the rabbit hole

Bushwacked replied to Bushwacked's topic in Handtool Discussions

Ah ... no doubling on chisels it was Narex or Japanese. The Japanese seem to have solid reviews and from everything I have read hold a great edge too ... so just figured I would toss them out as an option as they are pretty much the same price as the Narex set I was looking at. Since I am new to the handcut DT, is 1/2" a popular size? -

So this has been a slippery slope ever since my goof on the coffee table. When Kev through out the idea using chisels to correct the problem ... I have gone from chisels, to sharpening them, to now DT and the the tools needed there. So far, I still just have everything in my shopping carts because I am not sure .. For DT equipment I have been looking at: J Katz Moses DT Block: https://www.katzmoseswoodworking.com/new-products/81-clear-urethane-katz-moses-magnetic-dovetail-jig-and-90-degree-crosscut-guide SUIZAN Japanese DOZUKI Dovetail Hand Saw 7 Inch: https://www.katzmoseswoodworking.com/new-products/suizan-japanese-folding-dozuki-dovetail-saw-95-inch-k375m Buy both those together from J Katz and there is a 15% discount. Puts it at $61 for the combo. Marking Gauge: https://www.amazon.com/gp/product/B00B3ZS2J2/ref=crt_ewc_title_oth_7?ie=UTF8&psc=1&smid=A2FYHGC4NSM6WF Marking Knife: https://www.amazon.com/gp/product/B00FAMG8J0/ref=crt_ewc_title_dp_6?ie=UTF8&psc=1&smid=ATVPDKIKX0DER Fret Saw: https://www.amazon.com/gp/product/B00ATPMHN4/ref=crt_ewc_title_dp_5?ie=UTF8&psc=1&smid=A7O51HGOUZ91S Chisels -- Narex: https://www.amazon.com/Narex-Republic-Woodworking-Chisels-863010/dp/B00GPC74ZQ/ref=sr_1_2?crid=16FX5GWD1NHVC&dchild=1&keywords=narex+chisels&qid=1606660147&s=hi&sprefix=narex%2Ctools%2C192&sr=1-2 Or HACHIEMON: https://www.amazon.com/gp/product/B07TT3VCJD/ref=crt_ewc_img_dp_4?ie=UTF8&psc=1&smid=A1J84LOS58TPNV Then for sharpening ... SHAPTON Ha No Kuromaku Ceramic Whetstone: https://www.amazon.com/gp/product/B01FYEYKEI/ref=crt_ewc_title_dp_3?ie=UTF8&psc=1&smid=A3TCNCNGLOHBSA DIA-FLAT LAPPING PLATE: https://www.amazon.com/gp/product/B005FUHTDG/ref=crt_ewc_title_dp_2?ie=UTF8&psc=1&smid=ATVPDKIKX0DER What are yalls thoughts? Anything I am missing or anything that could be switched out? Also, since I dont have a workbench with a vise, I would also need to build one of these Moxon Vise:

-

Ah I didn’t know he taught for mark, that’s cool. I guess that would explain why his YouTube dried up. wimberley is just south of Austin ... so kinda close to both of us. Like a 3 1/2 hour drive for me. yes all that makes sense ... need to refine my technique a little ?

-

So I always enjoy watching people’s ‘ how to mill’ videos and see if I can pick up anything to improve my flow ... a new guy I found, Philip Morley ... who is not super active it appears, which is a shame .. went over his tips. my question is more surrounding the pressure or lack there of while jointing... this is something I’m pretty much the opposite on. I’ve always put more pressure while jointing but maybe I am wrong? How are y’all doing it?

-

Yes, the poplar would be for only painted parts .. Then pine for the stained part like a top or shelves or something. Figure that might be easier than dealing with all pine?

-

I mean I may have to give you a hard time about how your door is not flush ? other than that it looks amazing and like Kev said you probably shouldn’t loose sleep over it.

-

thoughts on this sharpening set? https://www.amazon.com/gp/product/B01FYEYKEI/ref=crt_ewc_title_dp_1?ie=UTF8&psc=1&smid=A3TCNCNGLOHBSA

-

That is what I was thinking ... a 2" x 6" by 8' is about $1.44 BF ... not sure what my dealer sells if for though as I have never asked. Although, I have been debating on whether I should go the route of poplar for as much as I could and then if they really wanted the stained knotty look, use that for the tops or pieces that they want stained.

-

I’m curious how annoying is working with pine? I’ve never don’t much with it like the Big box stores pine vs my lumber dealers pine? Is there sap and stuff that will clog up my blades etc? Is one place better than the other to buy from? Had a request for some farmhouse stuff but not sure how much of a pain it is to work with.

-

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

Thanks! Wife really likes it so I guess I did good. Haha! the kiddos were running free while we were cooking. So they destroy the couch and throw pillows everywhere for some reason. thanks! Hmmm gonna have to remember that trick in the future. Hah! Thanks! -

oh didnt know it destroyed that too ... that sucks! Maybe this is a sign you should upgrade to the Shelix head ? ... that is random that it just exploded like that without hitting something or the board exploding as well with it causing the issues

-

wow! well, glad it didnt completely blow up the machine ... you have any spare blades of are you having to order another set?

-

oooh crap, scary stuff!! was this end grain for face grain?