Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,605 -

Joined

-

Last visited

-

Days Won

98

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Everything posted by Bushwacked

-

Axiom Stratus Air Cleaner/Air Filtration....

Bushwacked replied to RxR Sawdust Station's topic in Power Tools

LOL! you mean at least 3-4 times right? Denial of it not working right the first time due to cheapness doesnt set in just yet ? -

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

Hah! I mean ... Yes, I could always do that ? Probably the easiest fix would be just that. Just looking for other options since I could practice new techniques. I might have to end up just doing that, but I might piddle around and do a few other things just to try it out since I can always cut it out and rip a new piece. -

I dont have that set, but I do have another, I think from Bosch? Maybe? The 2-3 times I have had to use them, they have worked super easy and no hassle. Assuming most are the same so you should have a pretty good experience with those as well.

-

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

Ah, ok ... the domino makes sense now :). I will give that a go and see how I do. Is your kid getting out of woodworking or just more into power tools? But yes, if he is looking to get rid of things, let me know I might be interested! -

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

so 2 questions ... 1) Making my own domino, wouldnt that still be end grain on top showing? Am I misunderstanding yall? 2) If I were to go down the chisel route, which ones should I look at? I dont mind buying 3-4 or something like a starter pack. Then I will need some stones right? Or some way to sharpen then and to flatten the back of them before using ... right? Or is that not really needed at least for this first use? Would the Narex line be good enough? Some good Japanese set out there? -

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

What would your answer be if I told you I had 0 chisels ... still the same? -

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

And my WTF moment for this project ... 3/4 thick ... push a #6 bit all the way through on the 20mm setting. Nooooot happy about that one. Going to glue the domino in there and cut it off hoping the stain my wife wants to put on here will help hide it as well. Thoughts? also... for finishing... I’m assuming I finish the top on top/bot and all sides. The finish the ply on top and bot? Leaving the sides I fished for the glue from the apron. Now for the apron piece .. do I just finish the front? Or put like one coat on the back so it will glue still? need help on the thought process there please. -

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

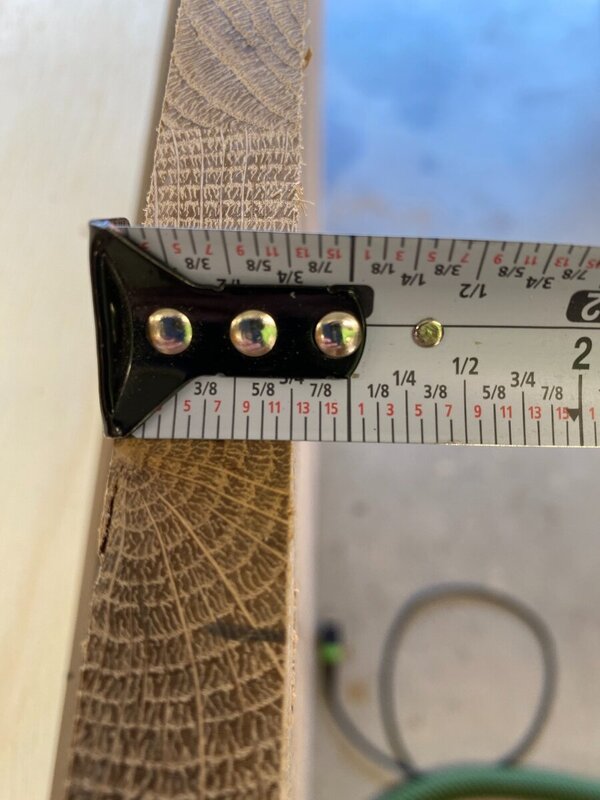

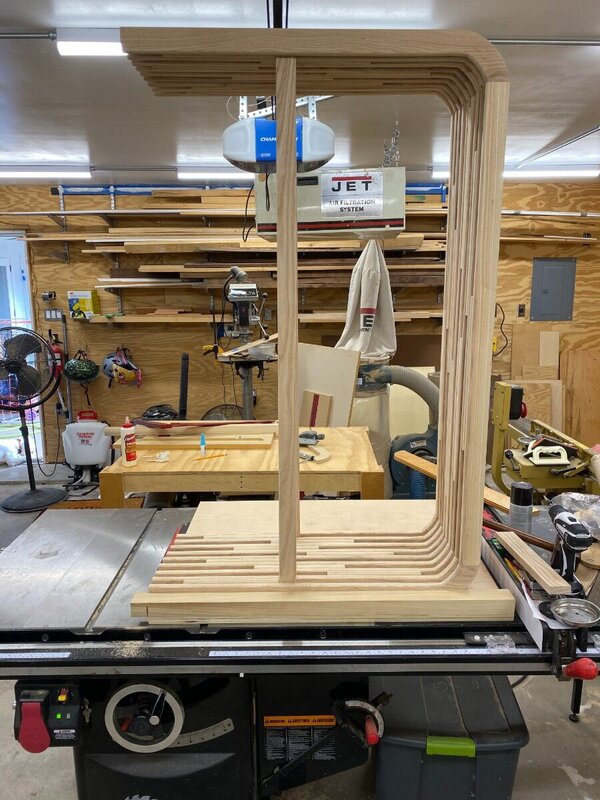

More work done and now I’m in carpool line for kids ... Working through how low to go with the dominoes... ended up being like 27ish reveal?? it’s tough to balance it on there as the ply is about 1/32 sticking out on each side. legs installed where I want them and to help get the 4th piece of apron on. Only way I could find to get clearance to work on it haha. some closer pics of the legs ... -

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

This goes to the convo above where I will be wrapping the whole thing with an apron like the picture shows. The consensus was the wood movement would blow apart that wrapping and mitered corners if I connected directly to the top. So the ply bottom came into play where I could attach the apron to that and leave like a 1/32 or so gap all around so the wood could move and my miters would stay safe. At least that is the going theory on that at the moment .. -

Coffee Table For The Living Room

Bushwacked replied to Bushwacked's topic in Member Project Journals

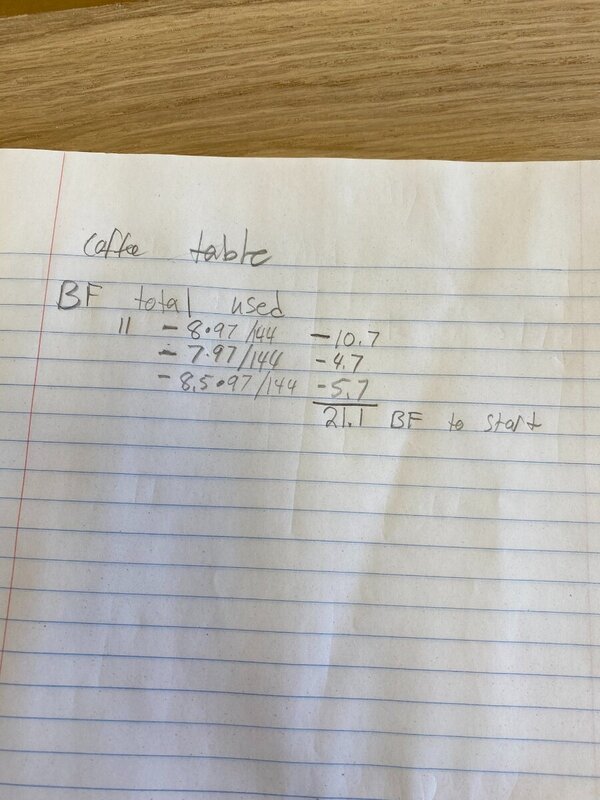

Getting time to work on this one now that the sofa table is done ... A rough estimate of wood used .. trying to track all this now to have better ideas in the future. Everything milled up and ready for dominos I glued 2 halves together last night .. Then glued those together this morning and waiting until later before I start working on that to let the glue dry. Next, going to cut out the support base for it ... the 3/4 ply. I was thinking to attach it, I could put a location domino in 1 side, just to make sure it lines up the same every time and might make things either when attaching to the ply to make sure its in perfect position?? Thoughts? -

Bushwacked Garage Reno Complete in 2020 sometime ... Hopeful

Bushwacked replied to Chet's topic in Member Project Journals

While the glue dries on my other coffee table project (new journal coming for that one) I figured it was time I could make some quick updates. I needed to get the cabinets inset, as that is what the hingers are even though they sold them under an overlay name ... all good just a couple trips to the table saw and my trusty new panel sled ? I needed 28 1/2 ... I think the sled is good to go! I only got to 1 door before lunch time, still need to work on fitting the door a little more but it is in there and looks way better ... well it will once adjusted to the reveals needed. Next I need to figure out some pulls ... I am thinking make my own to keep the look. Not sure I want to just toss 4 cheap pulls/knobs on the doors. -

Axiom Stratus Air Cleaner/Air Filtration....

Bushwacked replied to RxR Sawdust Station's topic in Power Tools

Also this email showed up again ... how crazy do you want to get with this? ? https://www.harveywoodworking.com/products/gyro-air-g700-dust-processor -

Axiom Stratus Air Cleaner/Air Filtration....

Bushwacked replied to RxR Sawdust Station's topic in Power Tools

I have the Jet version ... bought way back when it was always on sale for like mid $200's I believe it was ?? Seems to do an OK job getting dust filtered, I have to replace the filter a decent amount while working on projects and running it frequently. Not sure how well it is doing, just going off the amount of dust in the filter ? -

I’d be curious on shop temps as well. I’d be happy with 65ish or so to work in. those look real nice but I’m only in 400 sq ft garage so a bit overkill I think.

-

haha, not right away ... the glue up and 4 hours of hand sanding beat me down!! I am going to switch and build the coffee table my wife is wanting. Then I might come back to the coffee table companion for this.

-

Would love a pellet stove, however I would pretty much be paying $700-1000 for one. Down here in Texas they are not popular at all ? Found one on Craigslist for $600 but would have to drive about 3 hours each way ... Looking at smaller new ones, still $1k +. Going to keep an eye out for one though, just not sure how lucky I will get unless I end up driving to like Amarillo or somewhere further up north to pick one up. Also, curious ... If I pip one in, can the main piece be removed during summer to free up space? Or pretty much once it is in, it is in? Is it this one? How safe do you feel it is in your garage? How long does it take to heat up your shop to like 65-70? I was also thinking about one of these ... https://www.homedepot.com/p/Mr-Heater-80-000-BTU-Propane-Convection-Heater-MH80CVX/305092292

-

Yep. Out of ignorance I didn’t think it would be this tough haha. Always learning and definitely jumped out of the comfort zone. I like to test myself and dive right in ... sometimes it’s good and sometimes it’s a glorious explosion of wrong ? here is a staged photo inside ... looks good inside

-

I think this is the right spot for this? If not feel free to move to correct spot ... I am looking to get some heat in the shop (my garage) for the winter. A Mini split or something like that is not an option, so I am going to have to go the propane heater route ... Has anyone had any experience with them or know of a quality one that will work? I looked at Home Depot the other day and Tractor Supply and they had several models, but I just dont know which one is safe/good quality ... Thoughts?

-

Axiom Stratus Air Cleaner/Air Filtration....

Bushwacked replied to RxR Sawdust Station's topic in Power Tools

To your point #3 Kev ... Mark (Wood Whisperer) and Jay Bates made videos on shop air filters and the one he runs and what it actually does: Take a look at those, they may be able to handle a few of your questions too. -

Hah! Well, it is a great shirt ? Thanks! There is definitely some mistakes on this one, but overall I think I corrected them enough with yalls help to make it nice again. I did learn quite a bit so that is always good! Now I will be moving on to my next project, a coffee table for the wife for our living room. Thanks! It was fun and very challenging for sure! Thanks! Fun yes, but so glad to be through with it and the glue up haha. So for the last thing today ... I still need to add the felt pads on the feet and then the rubber pads for the glass on the cross braces so it doesn't slide around. I will get a pic or 2 of the fully completed look today though.

-

very nice! Everything has a good spot now!

-

I have already started one of mine and figured I would post mine and we could all post what we end up making for Christmas as gifts ... like all those amazing reindeer and cutting boards etc etc. Just some simple tea candle holders .. took about 2 hours to make all these. Finished with a couple coats of shellac

-

now for last night and todays activity ... Got my ARS on wiped on and ready for spraying ... Love my dutch door, this is how I run the spray gun for finishing. Then, you know, plugging Kev's amazing shirt ... No he did not pay me for this amazing promotion he is receiving ? Checking out the final coat of spray finish, I put 3 on there.

-

now that we can post again ... here is everything to get caught back up. All together and done with gluing finally haha ... A few legs slipped out of place somehow and cause some wobble when standing. Guess I should have gone with exact dominoes and not the middle looseness ones. Lesson learned. So I built me a panel sled based off Kev's video for a refresher .. I got these runners off another FB page, 3D printed so I figured I would try them out. Had them for a year + now waiting on building some sleds. GREAT fit, just small, so I needed 2 of them. Test cut flipped and checked and perfect! Just a little tear out, but this wasnt my plywood blade ... Now that the panel was a perfect 90* (or as close to the eye as it can be) I through the table on it and cut the feet back to the same size. Not sure if there were other options on how to handle this, but this is what I came up with haha.

-

ah, thanks for the info! Man DSL ... have not heard that thrown around when talking migrations in a loooooong time ? No worries, we wont be going anywhere over this! This is just a little hiccup and plus, Coop would have to learn a new password for a new site and I am pretty sure his brain is maxed out on passwords with all 2 in there now ?