Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,467 -

Joined

-

Last visited

-

Days Won

54

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Everything posted by Jamie

-

It was on the face grain. Made a light skim pass and lowered the head 1/4 turn and all hell broke loose.

-

Well my morning isn’t going to great. Making a cutting board as a wedding gift. Went to plane down the first glue up and on the second pass WHAM! Cutter head came apart on one corner and metal shot out of the machine.

-

Wow! What a difference! I really like the doors on the peninsula, what a neat idea to get at a troublesome area. Great job!

-

Yeah I will agree with that. Definitely a head scratcher. I really haven’t ever played much with m and t. Coming from a cabinet background it’s dados and pocket holes. Furniture is a new challenge for me. I do like it tho!

-

Thanks! It looks sharper than it is. It’s a 10 degree cut so not sure if it will be an issue. These are actually the first angled tenons that I ever have cut so not to sure on it. Was just happy they fit!

-

Yeah I did use the same tenon jig to cut the shoulders. But with the angle I didn’t cross cut the angle on the table saw. I’m thinking I might have confused you with the “lot of cuts” comment. What I was referring to was it’s just a lot of parts. With the tenons being offset and angled it is a quite a few different setups. With the parts being 1/2” thick it made for a lot of small short cuts

-

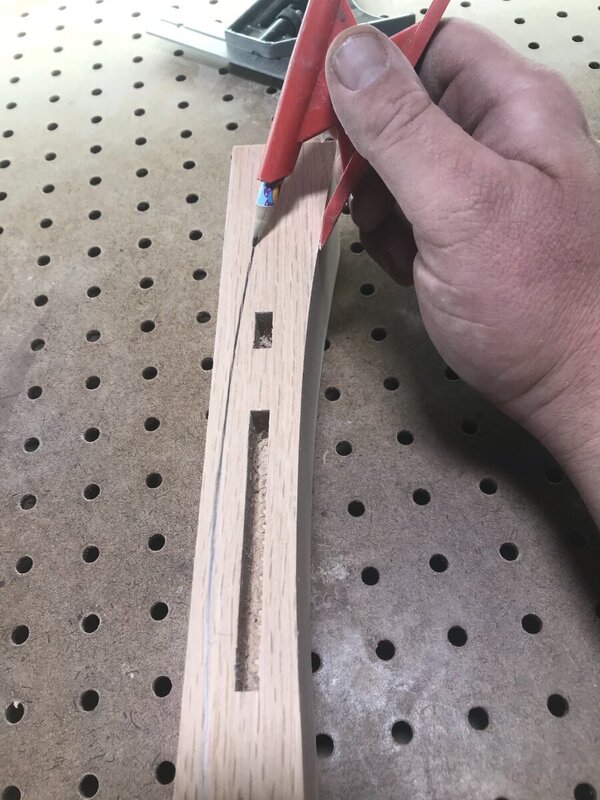

Got started on the back slat tenons, lot of short little cuts to be made with the bottom tennon being angled added a little bit to the process. Made a lot of test cuts to get it dialed in. Was a little tricky getting them just right as with the angle it made it a challenge to measure. Had to make the final shoulder cut by hand. Used bevel gauge and a knife to mark it out then just nibble away at it with the chisel. With 3 slats per chair this process will take a little time. One side all cleaned up. Did get the parts to this chair all finished sanded and dry fit. Really happy how they are coming. Might have to figure out a good way to clamp the back slats, with them being on an angle I can’t seem to get a good straight pressure applied. Thinking I’ll have to cut an angled clamping cull of some sorts. With the hand work and wait time on the glue I’m going to try to approach it one chair at a time, do the hand work and glue it up before going on to the next step.

-

That’s a crock! Isn’t there some law that they have to honor the price? Thought I heard that at one point.....otherwise restaurants could say 99cent prime rib then charge you $25 or whatever they want. Pretty sure they have to honor it. It is kinda weird tho that the price changes that much during the day. I bet I checked it 4-5 times and it was always different.

-

That is a smoking deal! Hopefully they honor it!

-

They are back up to 1369.99. Hope you got one ordered!

-

Great question! No......I never gave that a thought. I did try a couple different 1/4 chisels and neither one fit. Will check them tonight tho!

-

Thanks! Good idea. I was thinkin the same. That 1/4" was also a little undersized. After checking it with the caliper was getting 0.23. Which really isnt a big deal other than my 1/4 chisel wouldnt fit into the mortise.

-

I do the same on my out feed table. It seem to get me closer than just guessing. if a guy made the jig I think I would cut a notch in it where you could get a caliper to take a measurement as well. Just a thought.....

-

Thank you sir! I’m happy how they are coming together, won’t take much force to pull them tight.

-

Very happy! Yeah I don’t think I’ll make that self imposed deadline. Maybe by Christmas ? Did get to spend most of today out in the shop ? Getting back to work on the chairs has put me back in a good mood. Have been mad at the world for the last couple of weeks. The shoe rail was the first matter of business today.....it has a bevel on the top 3 edges and a curve on the bottom side. First bevel was pretty straight forward with a easy rip on the tablesaw and a light pass over the jointer to take the saw marks out. Made a template for the bevels on the sides and for the bottom curve for marking all the shoes out. Cut the side bevel and curve on the bandsaw and cleaned them up with the belt sander and spindle sander. Here is the completed shoe rail. Made another template for the curve on the crest rail. After the first curve was cut and cleaned up I used a handy little scribe tool to mark the back of the curve. Compiled crest rail. Had a nasty crack show up in one of the crest rail parts. Was pretty happy at this point that I had made an extra one for this occasion. Had to dry fit one for fun! Put together with no clamps so the little gap will pull right together.

-

I seen a jig to size it. Basically it was a 12x12 piece of ply with a bolt through the middle that had a wing nut and washer. Stack your dado set to the width you want and tighten it down to act like the arbor nut. Then slide a piece of scrap up next to your blade stack and check the width to your piece.

-

That is slick! Honestly I watched the video and was guessing a price I was shocked to see that it was only $210 I was thinking that the red gold would’ve been $350-400. Not that I’m going to get one, neat product though! Thanks for sharing!

-

Weren’t they gator bits or something like that. For some reason I also have “ez out” stuck in my head.

-

We’re back in business! Chisel showed up, not really happy with the quality of it as the points of the chisel are not square to each other. I didn’t notice it right away but after I started sharpening it the points being out of wack showed up. Don’t think it will hurt much but still bothered me. Decided to give it a try instead of waiting for another chisel. Worked better than the first one! Well in that I mean it didn’t break. I did have to make a slight adjustment to my layout line to make everything center up. For some reason my template was a touch off on the width of the right side mortise. Did some figuring and checking with a caliper to get it dialed in. Not a big deal and they were all marked the same so just had to cut about 1/32 over the line. Cutting the mortises on the shoe rail had the rikon about maxed out. Had about 1/4 clearance from the bit to the piece. Made it a little awkward to press the bit into the wood as not much leverage on the handle. Actually had to clamp the mortiser to the bench to get it to work. Which some of you guys know how heavy this bench top machine is. Am happy to say that all the mortises are cut! Now onto shaping out the crest and shoe rails then on to cutting some angled tenons.

-

I’ve used bits like that before. Had good luck with them!

-

I’d cut a Bow tie or grub it out to a circle and fill with epoxy to make it look like a knot hole. Wouldn’t make it look like a true circle but more of an organic shape.

-

Axiom Stratus Air Cleaner/Air Filtration....

Jamie replied to RxR Sawdust Station's topic in Power Tools

Lol you can call me whatever ya like! My being a cheap ass has cost me a lot of money. Why do it right the first time when you can do it cheap and do it twice. -

Well the auction ended today. Didn’t get much, everything seemed to go really high in my mind. Heck some of the clamps went for better than new money. The bigger tools I thought sold high as well. I ended up winning a couple shaper cutters and a kreg shelf hole jig that I can add to my existing one.

-

+1

-

Bushwacked Garage Reno Complete in 2020 sometime ... Hopeful

Jamie replied to Chet's topic in Member Project Journals

I have cut one pull using a quart finish can as the template for the curves. I to need to make a bunch of them.