Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,605 -

Joined

-

Last visited

-

Days Won

98

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Posts posted by Bushwacked

-

-

12 hours ago, Coop said:

Have you gotten to the dc piping to your machines yet? That would be my biggest concern before you put good money on a muffler. Make sure your system is adequate.

I hooked up the CNC for a few run and its working beautifully for that ... I started working on the ducting for the garage, but need 1 damn piece no HD had in stock around my area so had to order it and should be here tomorrow. Hoping to get everything installed and hooked up by this weekend?? depends on how cold it is in the garage and if I feel like doing it haha.

-

On 2/19/2022 at 4:57 PM, Kev said:

I was so intrigued by the "muffler" that I ordered one for my system.. Going to give it a test drive when I get home.. Will probably be a little late for your needs but, just wanted to toss it out there..

I might even take a look at this as well. the first couple tests with the box were not all that great. I do have some gaps on the sides which I am thinking about filling, but thinking now if its even worth it as its still pretty loud. the panels did not cut out 50% or even close haha.

So that is why I may give that muffler a shot and see how that goes.

-

15 minutes ago, theduke said:

Been on kid duty almost all day so my brain is a little bit fried, but the box is to encluse the DC motor to reduce noise I'm assuming... If so, have you considered using MDF? I know most subwoofer boxes, at least for vehicles, are made out of MDF due to noise (but I'm not sure if it's a good thing or a bad thing for this situation, which is the reason why I'm asking). Thanks for your input!

so, I am sure @Kev can go way deeper on the MDF application and all that based on his experiences .. I dont really know much about that.

However, the box I am making is actually to reduce the exhaust sound. The motor is actually not that loud compared to the exhaust. So that is where I am attacking this first.

-

welcome! It would be awesome to see a journal of a clock build! Beautiful work like Kev mentioned for sure ... Looking forward to the seeing more on the current builds too

-

32 minutes ago, Coop said:

Thanks. The reason for asking, I’d like to try and make one and using a router, make it completely round. How thick do you think the sides should be after routing?

mine are 3/4" with 20"D base and seems about right ... I think anything thinner might look "off" ?? If you were just a little under 3/4 I think it would be fine but not much.

If you were making a smaller one, I think you could get away with 1/2"

That's just my thoughts lol

-

1

1

-

-

8 hours ago, Coop said:

Did you mill it down to 3/4” before cutting the pieces?

yes

-

4 hours ago, Coop said:

I bet he meant the outside ring pieces.

What was the original thickness of your board for the outside pieces?

How did you cut the bottom?

ah missed that comment ... yes outside rings.

4/4 original board

my CnC just to get it done quick

-

1

1

-

-

11 hours ago, Woodenskye (Bryan) said:

Ridged foam will be stronger than ceiling tiles. Your never going to reduce sound to nothing. Sound will reverberate off flat surfaces, which is why music studios and other sound proof rooms have the spike foam on the walls. In your box you may want to enclose it all with 1/4” ply and then use spray foam.

what rigid foam are you talking about? It will be enclosed with 3/4 ply ... its gonna be a heavy B!

6 hours ago, Kev said:There's a lot of science behind sound proofing. While your theory appears solid, that's not quite how it works. The 2 items together will do better but, not my those numbers.

I was able to do pretty well in my studio. The sounds you're talking about were actually the easiest to control. These were the mid to high frequency sounds and they were actually controlled with the construction of the walls. In my case, each opposing wall was layered slightly differently because this also helped. On one wall I would do a layer of soundboard, a lathing strip (to create an air space) and then a layer of 5/8 drywall. On the opposite wall, it would be a double 5/8" drywall with the lathing strip between.

The foam you're referring to is for the purpose you reference but, not for the purposes of sound proofing. It's to control those frequencies that cause feedback on microphones. I have truck loads of Auralex foam in my studio and it works well to cut down on the natural reverb in a room. They also make it in decorative forms for those of you with theatre rooms that would like a little better audio quality.

One last item but, I don't thing this is really an issue for BW. Low frequencies are not touched by the foam! The only thing that deadened that was the way the walls were layered in my studio. My studio was ~15' from my house. My wife would tell me if she turned the TV off and make the house quiet, she could hear the kick drum and sometimes the bass guitar but, that was it.

Sorry for being long winded.. Probably more info than anyone really wanted...lol

haha all good, I like when you get on a roll and I get some paragraphs out of you ... always learn something.

I was thinking about doing a double layer with a gap in the middle with those tiles as well to possibly make it even better. Hopefully will have a good amount of it finished up tomorrow to hopefully get a test on it

-

1

1

-

-

Sanded with a 2000 grit foam pad to just get the nibs off after spraying it … then applied my BB conditioner and this one’s a wrap! Learned a good deal on this one haha.

came out way better than I thought it would a few times after some issues but if I ever have to make another one it shouldn’t be as bad haha

thanks for the help through this one guys!!

-

5

5

-

-

3 hours ago, Kev said:

I saw this on one of the groups I follow.. I haven't seen it explained yet but, it sure looks like a muffler and I thought about your struggles.. There's certainly some parts of this system I don't like but, that part caught my eye..

Update.. It is a silencer made by AC Infinity.. https://www.amazon.com/AC-Infinity-Reduction-Hydroponics-Ventilation/dp/B0829F2VXP/ref=sr_1_2?crid=3P7YSVBLZV7O6&keywords=ac+infinity+silencer&qid=1645007602&sprefix=AC+Infinity+s%2Caps%2C103&sr=8-2

oh awesome! Definitely will be looking into this once I get my box built ..

So dumb sound question ... IF this thing reduces sound by 50% supposedly, and those tiles I linked above reduce by 50% as well ... is it safe to say I could, in theory, reduce the sound by 75% with both?

-

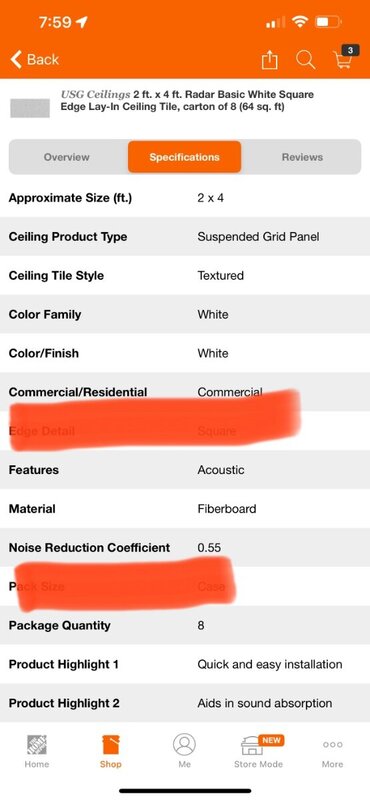

Also .. talked to my bro in law about noise reduction ideas … he thought the powerful blower might blow apart the more porous foam type panels. He thought maybe the ceiling tiles might be better.

something like those and just double them up. the NRC is 55 supposed to reduce by 50% ish which should be good enough I think.

-

I must be behind ... I have never seen either haha

-

1

1

-

-

Got some more work done on it …

then started on my super silencer box build 🤣 .... It had been so long since I worked with HD 2x6 pine, cant say I missed it. cupped/twisted/garbage and those were the straight ones haha. I had 1 board, THANKFULLY, I took to the bandsaw after it gave me some issue on the tablesaw that blew apart the last 6-8 inches there was so much stress. Put them back together after that, there was like a 3" gap in the widest middle part of the boards

without dust collection it’s such a dang mess after just a little cutting. It’s crazy!!

-

3

3

-

-

48 minutes ago, Kev said:

Dbs are dbs regardless of location!

true, just thought it was blocking out more dbs ... have you thought about finishing it out or you good with how it is now?

-

4 hours ago, Kev said:

lol.. Hearing protection is required (technically) at 85dbs.. Of course mine is too loud as well but, I haven't fixed it.

even behind the wall?

-

2 hours ago, Coop said:

Great tip for people coop! Any reason you didn’t add in the cyclone attachment before the barrel?

-

There’s the noise readings I’m sure it will muffle a little bit more with everything hooked up, but for now it’s hitting around 90ish dB

-

-

I did just stumble upon this ...

Which leaves me with a couple questions ...

How is he cleaning out his fine dust? Assuming after a year or so it would need some cleaning?? Just unscrew from wall and clean?

What is that foam stuff he is using? Standard Insulation panels?

Would adding 3/4 ply instead of the 1/8 hardboard from what it looks like add even more noise blockage?

Not sure what type of outdoor paint/protection would be needed to stop rotting from the elements?

-

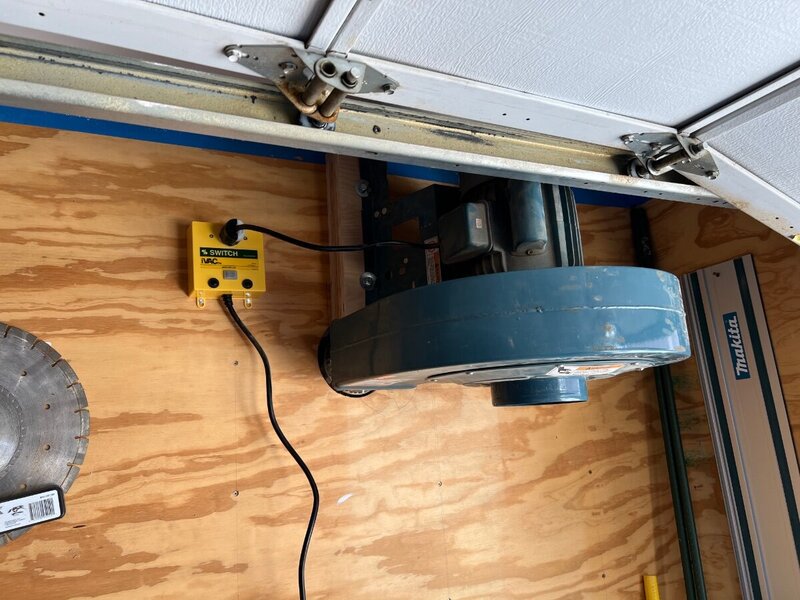

got the dust collector mounted and everything ... did a noise test and daaaaamn this thing got louder is seems. Wife heard it and threw a fit about pissing the neighbors off. Soooo now I am trying to figure out a way to decrease the noise of the outside vent. Anyone got any ideas on muffling the sound?

I found this ... https://billpentz.com/woodworking/cyclone/muffler.php Not quite sure what the final product should look like since none of the pictures show up and some of the materials I am not familiar with.

I will go grab pictures of it in a little bit, forgot to get them after installing it.

-

very nice Coop!! Will the 43 to 38 drop in suction actually be noticeable?

Also, what are the wooden hanger attachment things holding onto the pipes? How are they attached to the ceiling?

-

16 hours ago, Coop said:

I like it! You’ve given me ideas. If you could make changes, where would they be?

so overall, I like the way it came out ... the bottom is annoying with the gaps, but I guess you dont really see it all that much so I can get past that. The height of the edges I think actually are a perfect height, 2" on those, with the 1/2" bottom. Still real light weight ... but I did use alder, so weights may vary with some other woods.

- the glue up .. I would look for a better way to go about that. The struggle was real with that one haha. Not sure if there is one?? But I would be up for trying something else, it was messy and was probably red lining the working time of the glue.

- I would more than likely also go with Kev's idea of the donut model to make it a perfect circle on at least the inside (ties in with the hatred of the gaps) Plus this would alleviate all the glue that I apparently missed cleaning up on the inside that was an absolute nightmare to hand sand off.

- Cutting out the pieces, I would make sure the sacrificial fence was on both sides of the blade. A couple people had some tear out and when glued together those spots look kinda goofy.

-

1

1

-

-

15 hours ago, Coop said:

I just realized that in another thread, you were contemplating routing this thru your ceiling and out the soffit? So you decided to go directly thru the wall? Nice cut.

Oh, by the way, your HOA has contacted me and I’m sure others on here about dust generated by this type of system. In your defense, I told them that it was done all of the time. I don’t think she was happy with my answer. 😀😀

15 hours ago, Kev said:Yea, if you let that thing overfill, all your neighbors will be calling.. Where I'm at, I laugh and call myself some choice names for allowing it to happen. Then, I get the leaf blower out and clean up the mess..

LOL! I cant wait to see what kind of dust comes flying out. I am curious on noise level of it blowing out there too .. think that will piss off the older neighbors more than dust haha

14 hours ago, Coop said:I didn’t realize that you have a 3/4” ply wall to mount the motor to. Now you have 3 ea. 3/4” ply. Bezos’s launch pad isn’t that thick! Screw it down and move on to the important and expensive stuff, the duct work. I just finished my re-location of my dc system and the hard piping and I love it. Sure makes woodworking more enjoyable.

You dont remember my garage update thread from like '20? 😞 But yes, 3 of the 4 walls are 3/4 ply to make mounting anything and everything easier.

Awesome to hear!! Do you have some before and after's of the new setup on here yet?

-

2022 garage shop updates …

in Member Project Journals

Posted

hah! all good ... I too was super surprised at how loud the exhaust was over the motor ..