Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,605 -

Joined

-

Last visited

-

Days Won

98

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Posts posted by Bushwacked

-

-

On 3/23/2022 at 6:27 AM, Kev said:

First video for this project will drop on Saturday.. That's when I'll move this piece to the public forum..

Official due date for the baby is May 13th.

uhhh you tell momma to hold on 2 more days!! May 15th is the better day to be born ... just sayin 🙂

-

1

1

-

-

Yes, I am on a finishing kick right now ... leave me alone 😄

I thought it was interesting how he broke down, not necessarily their performance, but more of the size of the project on how he would use them ... His points make sense on it and might be something that helps others in here??? It helped me for sure on just seeing another way to think about finishes ...

-

1

1

-

-

Looking around more on this since it seems interesting ... I also found this article too

https://www.popularwoodworking.com/finishing/soap-making-clean-finish-2/

-

Saw this used in one of his videos so I went looking and found more on it ... Never seen or heard of it being talked about, so curious what you all think about a soap finish on light wood to not turn it yellow/darker ...

Also, if you are looking for some nice quality build videos and stuff, he is great to watch. Several of his videos make me want to grab a smoking jacket and some scotch and dim the lights and listen.

-

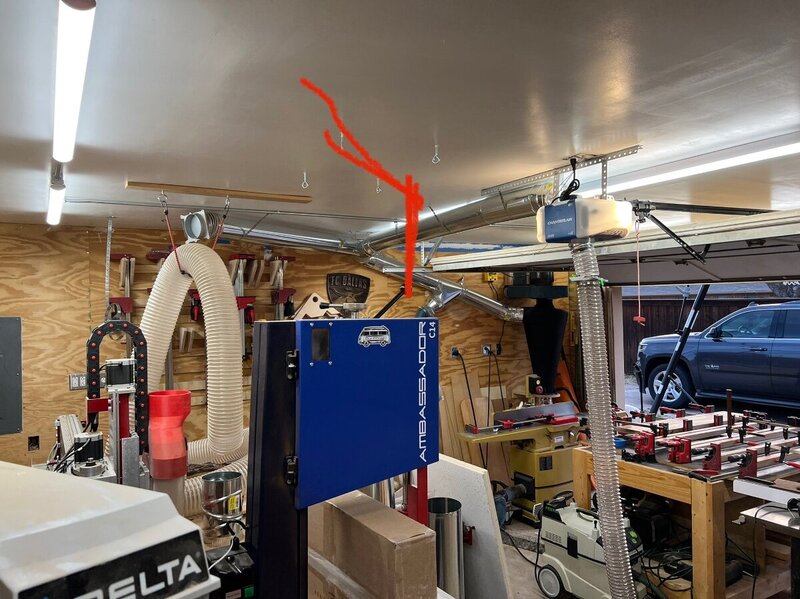

Got some free time so figured I should work on finishing the DC for now …

trying to figure out if I should hard pipe more toward the middle or if that’s decent? Testing it out it’s enough hose.. however it gets a little squirrelly when I get to the middle and under stretch bands on the middle. Maybe need to tighten the stretch bands a little to give it more clearance maybe. Still tinkering with that but curious if y’all have any thoughts?

-

51 minutes ago, Kev said:

Clean the rollers with rubbing alcohol. I would also run some different lumber through the planer to ensure it's the rollers causing this or if that's in the wood you've got there. See if this happens with a chunk of maple

ok, will give that a go tomorrow ... thanks!

-

1

1

-

-

5 hours ago, Kev said:

I think I'd consider coming down in a corner and running a hard line just under the rack on the wall. If that's possible?

I will take a look at that ... it is tight over there on that back wall with the circuit panel and several outlets to get between ... Going under the lumber rack wouldnt be too bad .. but I would need to put in 3 90's to get to the DC .. would that not kill the suction?

-

1 hour ago, Coop said:

The scraper is pretty neat. Where did you get it? I still use an old chisel.

Pretty sure Home Depot? It’s been awhile haha.

ok so my rollers on the planer left black marks on the wood I figured I could sand it out and I got most out. However now I am down to final height after sanding and still have some in some of the more grainy pieces. Any idea how to get it out? Also any idea what to clean my rollers with? Or what’s the deal with them?

-

2 hours ago, Kev said:

My scraper is so old and worn! Time for a replacement for me!

ya I am not sure how long the blade is supposed to last, but I have been pleasantly surprised with it ... still going strong after quite a bit of scraping on several projects

-

-

31 minutes ago, Coop said:

Coming along nicely. I’m sure I spent more on my 4” hose from Rockler than I should have but you have a fortune in hose, regardless of where you got it!

Speaking of relocating your machines, it sounds like me. Each of mine are in the same location as I placed them as I bought them. I probably should have moved them all out and did so shop re-organization before running my duct work. But just moving my dc out of the middle of my shop helped tremendously. Like going from a standard size bed to a king.

My goodness the hoses are outrageously priced!

yes putting my DC on the wall has been great!

-

-

On 3/5/2022 at 5:58 AM, Kev said:

I have a couple thoughts..

1. I would try and run your hard pipe further to increase the efficiency of your DC. If it's even possible for you?

2. I would run a drop for each machine and just add a Y and a couple blast gates. This way you're not moving hoses around when you want to use a tool. I would do this for the planer as well.

3. The "monstrosity" might look a little better with some brick veneering on it? Or at a minimum painted.

All in all, it's coming along nicely!

1) I was thinking about that ..

The table saw cant get much more hard pipe due to garage door and would be in the way for cuts since I cant get the ducting to the far right of the table saw without reorganizing machines. Basically turning table saw 180 and putting it where the outfeed/ work table is now and then moving that where the table saw is. Maybe something to look into??

For the jointer, I could easily do that, but was thinking its so close to the collector I am not sure that would actually matter and be worth the trouble??

For the bandsaw area .. this would probably help the most due to the distance away, but I just need to get the drop over there for now and see how it goes with the flex hose. My main thing with that is having a hard pipe a couple feet in front of the wood rack my be a pain. It is already interesting trying to get longer boards off and I use a good deal of space trying to maneuver them out of there. (I will get a better picture of that area to show)

2) most is up top, but for the planer ... I was giving this some thought on how to go about this. I do have to move the planer out to the middle of the garage normally in the middle gap by the table saw to get the room to run boards and then power as well. With that, I would need to use a flexis hose from the ceiling to connect it, then have some way of hanging it back up on the ceiling to get it out of the way. Have not seen much on easily strapping a flexi hose to the ceiling when not in use... I do agree, I am sure I will be getting annoyed on moving hoses after awhile, when 80% could have been solved during this setup 🙂 ... so working through some of the more iffy spots on how to handle it.

3) agreed, I just wanted to get it up and see if it even worked that well. Then finish the inside next before figuring out the aesthetics for that beast haha.

-

1

1

-

-

Got a little extra time …

got bandsaw hooked up …

what it would look like when in use …

how the main line runs in the middle

also … my main thought was I could move the middle hose around and connect to bandsaw when needed since it won’t be in use much. However I’m debating it on running a line over there anyways so it will have its own run … then the tablesaw run will only need to be pulled off for the planer when needed.

also, this monstrosity is done for now .. at least until I get the inside runs done …can’t wait to hear your thoughts on the duct silencer thing Kev! Think that would look way better than this if it would actually work on its own.

-

2

2

-

-

7 minutes ago, theduke said:

Nice work! It's pictures like these that make me wish my garage ceiling was a little bit shorter than 10' so I wouldn't have to be so worried whenever I get around to doing this.

lol I wish I had 10' ceilings ... cant count the times I have hit the ceiling while moving longer boards around haha

-

1

1

-

-

3 minutes ago, theduke said:

Did you use loose tenons for the end to end glueups in round 1?

no, didnt use anything for that, just glue.

-

-

-

2 hours ago, Woodenskye (Bryan) said:

Looks good

Thanks!

now just to slowly glue them up haha .. gluing each strip up on its own, then going to glue a little more than half up so I can still plane them, then glue those 2 together .. at least thats my thought on how to go about this

-

1

1

-

-

-

-

3 hours ago, Bob said:

I have used butcher block in 2 kitchens. I ordered from Grizzly, Search (grizzly.com). Even with a little waste the final cost was $13.23 a lineal foot, compared to over $60 for any other surface. When you factor in your time + the cost of the wood to make one, you might want to consider going this route.

Had no idea they even sold them haha ... although for the size I need I dont see white oak as an option. Also, looks like they are only coming in 1 3/4" size, so I would need to trim off 1/2" as well.

will keep an eye on them for the future though

-

also, been going back and forth on this ... as far as the sizing goes ... is there a rule out there for how wide each strip should be?

Like if this is 1 1/4" thick, should it be 1 1/4" wide strips or can you go 1 1/2-2" and just depends on what the customer wants? Have not seen anything generic out there for at least a starting point. I know in the end its all up to the customer but not sure what a good starting point would be ...

-

1

1

-

-

A parent from my kids soccer team wants a new butcher block countertop for a cabinet ..

going to be about 49x19” and 1 1/4” thick. White oak will be used.

Will more than likely need some scribing work based on talking with the dad.

plan to attach will be some silicone and then like 3-4 figure 8s.

Should get going tomorrow….

-

1

1

-

2022 garage shop updates …

in Member Project Journals

Posted

For now got everything but the CnC run done. Still pondering that one…

got the bandsaw done and had to switch how the lines were run from the bandsaw to go out the back now.

shortened the jointer hose so it didn’t have 5-6’ of extra hose just sitting there