Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,605 -

Joined

-

Last visited

-

Days Won

98

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Posts posted by Bushwacked

-

-

25 minutes ago, Kev said:

That's interesting.. I would have never thought about the "speed of application" in determining which machine I really needed.

what did you consider when buying yours?

-

if yall are curious what Fuji had to say when I reached out to them a little while back ... might be helpful for some ...

QuoteThank you for your interest in Fuji Spray and our HVLP systems.

Our inexpensive DIY series turbines (2-stage motor) are perfect for the home hobbyist who intends on spraying a handful of times a year.

Most commercial sprayers will look for increased power, which correlates with increased speed, and will therefore opt for a 4 or 5-stage turbine system.

A real-world example of spraying the face of a typical sized kitchen cabinet with latex paint (thinned 20% with water and using a 1.8mm air cap set), the following durations occurred:

- Semi-Pro and Hobby-Pro 2 2-stage 37 seconds

- Mini-Mite 3 or Q3 3-stage 22 seconds

- Mini-Mite 4 or Q4 4-stage 15 seconds

- Mini-Mite 5 or Q5 5-stage 12 seconds

As you can see, the higher the motor stage, the faster the speed of application.

Both series feature a Heat Dissipation Chamber to extend the life of the motor and will help achieve a fine finish with any material.

The main difference between the Mini-Mite and Q-series turbines is the sound. The Q-series is designed with patented noise reduction technology which reduces the sound of the motor by 50% and is ideal for situations where sound levels are a factor.

In terms of gun selection, you have the option of bottom feed and gravity feed guns. The bottom feed guns come with 1 Quart cups which allows for less pausing and refill. The gravity feed guns are fitted with 400cc or 600cc cups and allow for spraying in tighter spaces.

Most guns come installed with either a 1.3mm or 1.4mm air cap set, which is the ideal choice for most waterborne materials. When spraying high viscosity materials such as latex, you may want to consider the 1.8mm air cap set.

Note that thinning will be required, and you will have to experiment a with different materials. High viscosity materials can require upwards of 20% or more.

-

2

2

-

Hah! Now this could be interesting to bring back up ?

-

7 minutes ago, Kev said:

If it's messed up it's because I was drinking at the time ?

Hah! Hopefully the alcohol helped ?

-

1

1

-

-

10 hours ago, Coop said:

Incredible amount of work on the staff’s part, on this thread alone. Great job guys!

agreed ... thanks to all who worked on this one! I am sure it was enough to make you drink haha

-

Man it was like a quick stroll through memory lane being able to see everything on 1 page so far ...

Should have more updates this weekend as I should get some time to get in there and work on the shelves and face frames for the cabinets. Then after that I will take a stab at the doors .. I think .. for the upper cabinets.

Getting a decent idea of where I want things in the bottom cabinets too. Working through Beckett's closet build, it should me real quick what I tend to go for most so that has been helpful in making some decisions too

-

1

1

-

-

finally found it .. for some reason it thought I meant Key Woodworks ... which is another maker.

Also, since I just saw it and joined ... Kev, be sure to put the new URL on there when you get a chance

-

is there a link to this one? I looked for a few and found all sorts of crazy sites, just not this one ?

-

ah ok ... ya it is the premixed stuff. I have not ventured off and started making my own yet

-

23 minutes ago, Chet said:

You could do a wipe on or spray, water borne finish. That stuff hardly has an oder even while you are using it and is pretty much gone by the time it drys.

how about shellac? Need to look and see if I have any water borne stuff around ...

-

Well got everything wrapped up last night as far as building, gluing goes ..

Parts all cut to length ... 6" and 9" sized drawers for the 10" and 7" spaces

A quick sanity check of dry fit to make sure all fits well with the slides in there

All the drawers in there for storage ...

Now to finish, I have sanded everything down to 180 ... I am assuming i do not finish the insides of the drawers as the fumes will seep into his clothes ??

I was going to use Natural color Danish Oil on this as I have plenty for this.

-

3

3

-

-

haha! Yep, dang mgmt!

well ok guess I will stick with my method on setting height.

-

Well it was a busy 2 day ...

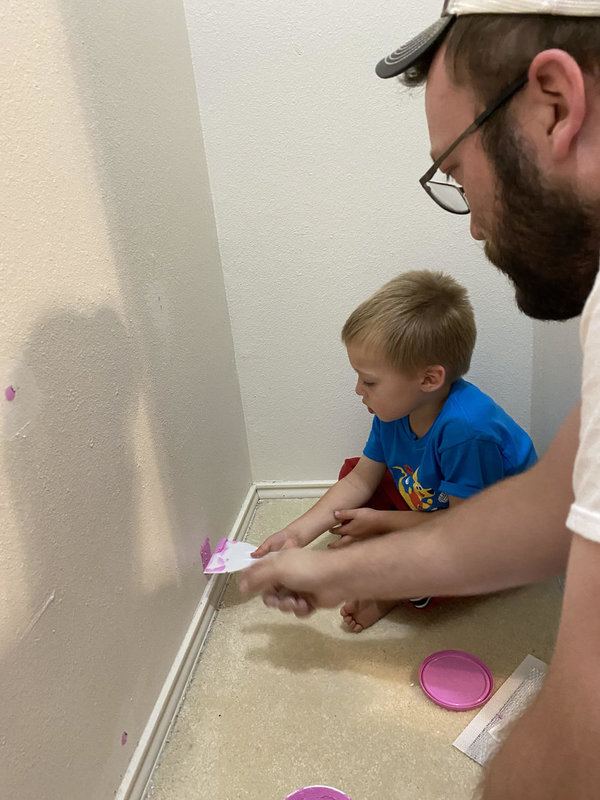

Got started with the demo and prepping/painting of the closet ...

He wanted it so he gets to work for it ?

edge banding ... this didnt turn out too bad. Took me a couple times to figure out how to go about it, overall I think they came out decent.

More shelf pins ...

Cutting the rabbets in the top and bottoms ... this was interesting to say the least, but it felt ok as I push it through in the gap of the outfeed and TS. Helped keep it steady for the most part. Definitely open to better ideas on this one if you have them ...

The only way I could figure out how to get everything on the outfeed table to make the assembly decently easy. They are just there to help keep everything from falling off.

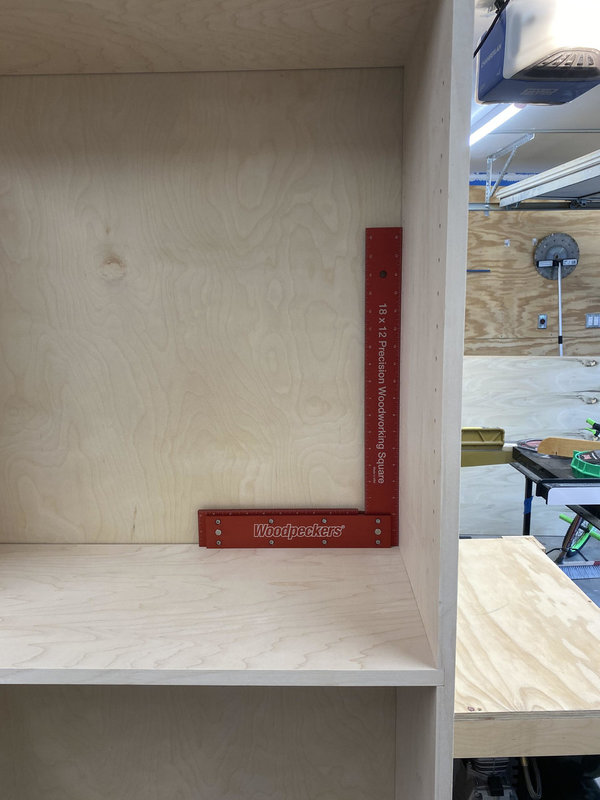

The smile I had when I got it together and realized, its only maybe a 64th out of square ... it is the first big piece to ever happen on ? haha

Drawers ripped out and read to cut to length today when I get out there ...

on a side note ... is there a better way to get more accurate height? It takes a few back and forth to get it the depth I need .. just curious ...

-

4

4

-

HVLP Sprayers

in Power Tools

Posted

ah ok ... whats the thickest you have sprayed? You have the Q4 right?