Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,605 -

Joined

-

Last visited

-

Days Won

98

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Posts posted by Bushwacked

-

-

Just now, Jamie said:

Boy that is quicker than I thought it would be. What is holding me up on a cnc is the learning curve on the software more than anything. Also the room they take up. Would have to find a new home for the boat if I were to get one.

There are quite a few programs you can use to draw. Depending on the machines some come with their own proprietary software.

have you ever used any CAD software?

-

1 hour ago, Jamie said:

That is looking awesome! How long did that take to set up on the cnc and cut? I guess I’d also be interested in how long it took you to program the cnc.

Thanks!

took about 20 mins in Fusion 360 to draw it out and get the gcode file output. To get the machine ready to cut about 2 mins. Took 35 mins with a 1/8” bit to cut 1/4” deep. Took 2 passes …

-

1

1

-

-

-

Got some work done today … might lose a few of y’all after this update 🤣

moxon vise coming through again to help!

so design change .. I was thinking maybe dowels but decided on through dominoes for an accent to the legs on the front faces …

test fit to get an idea on length of aprons and to see how the legs look overall. Happy so far ..

there’s one of my PECs double squares off the Epstein site … going 1” in from every edge

gluing up legs ..

-

2

2

-

-

they came out great! How thick are they?

-

1

1

-

-

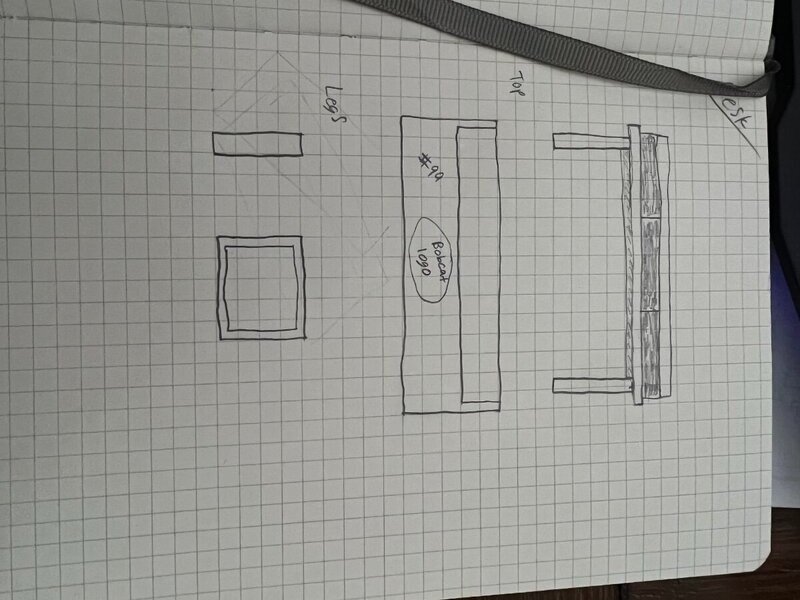

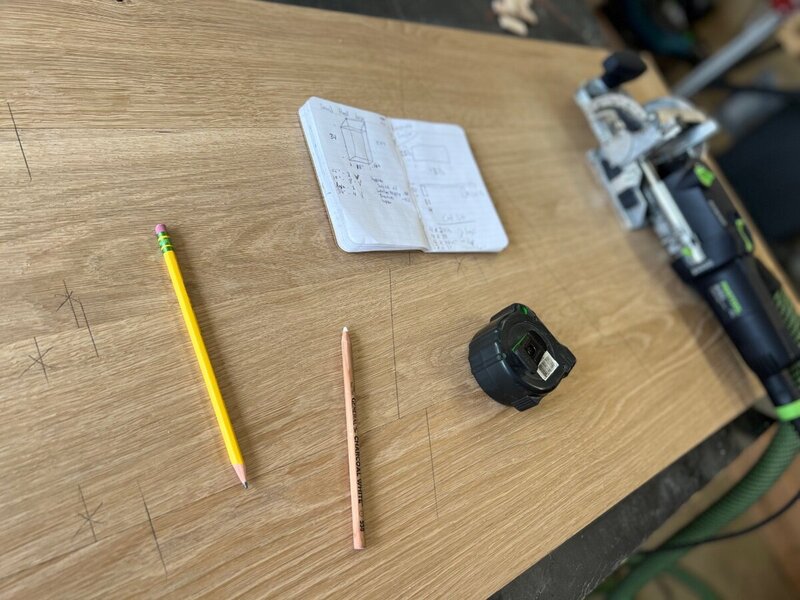

Getting ideas and marking things out

Got the top out of the glueup and my boy wanted to help scrape some glue … so heck ya I’m letting him help!

and he learned any mess we make we clean 🤣

random question… can you leave something in clamps too long? His top was in clamps for 2 days because I didn’t have time to take it out. I don’t see anything wrong was just curious …

-

3

3

-

-

very cool!! Would love to see these when done ... if you dont want to keep up with a journal

-

1

1

-

-

37 minutes ago, Kev said:

I think I got you fixed.. Take a look at the bottom now and the section should be open to you.

yep I see now, thanks!

-

1

1

-

-

4 hours ago, Kev said:

Video is up in the preview room..

If you don't have access to this room, let me know and I'll get you set up.

maybe I am looking in the wrong spot?? I dont see the champaign room 🙂

-

2 hours ago, Jamie said:

I like the light system idea, seems like it would be a lot more accurate than the laser.

Ya if I end up getting it I’ll post a review

-

1

1

-

-

27 minutes ago, Jamie said:

Thanks! It slides pretty smooth. Not as smooth as the glide mechanism on the bosch, but for a pipe system it is about as smooth as expected. I really like the soft start motor on it. Its gentle but starts a lot quicker than the bosch.

ya that is one thing I dont like about my dewalt ... you start it up and you better have a grip or it will pop out of your hand.

I was also looking into the light attachments for the dewalt, their version of the laser I guess ... definitely just a fun add on and not needed.

-

10 hours ago, Woodenskye (Bryan) said:

Just make sure your down wind when you fart or you my knock yourself out.

HAH! I will have to keep that in mind 🤣

10 hours ago, Jamie said:Hey that’s a deal! Nice find!

ya, super happy so far ... moves plenty of air and is pretty quiet

-

awesome, glad you got it all worked out it seems!! How is the sliding action? Smooth?

-

1

1

-

-

9 hours ago, Kev said:

Better yet, when she's done painting, tell her the color isn't quite right and it needs to be done again 🤣😂🤣

I was thinking exactly this LOL!! Get a lawn chair and sit in the driveway and critique like she did you while drinking some cold ones ... I would also question the "friend" on how they could like this person, might not be a friend much longer

-

1

1

-

1

1

-

-

-

37 minutes ago, Kev said:

This is what I ordered this time.. Hoping this isn't what you ordered that's loud...lol

https://www.amazon.com/dp/B07KDPCJ27?psc=1&ref=ppx_yo2ov_dt_b_product_details

hah! no those look nice ... this is what I ordered https://www.amazon.com/gp/product/B0006LBVDS/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 .. get what you pay for 🙂

-

36 minutes ago, Kev said:

The hardware is simple.. Just center it up and secure it. Nothing magical or tricky..

I'm trying some new hardware this time. The stuff I usually get at the big box store tends to be a bit noisy. So, I opted to order some more expensive hardware this time that should be much quieter. Frankly, the profit margins on these is so good that it was easy to absorb the extra cost and not pass it on to the client.

interesting ... what kits are you using? I ordered some off amazon and they are loud.

Can I ask a rough range of price on these?

-

-

do they have to be identical? Maybe do one with ARS/WB and then WB?

they look great though!

-

1

1

-

-

have you thought about Starrett also? I have one of their adjustable 6" I use all the time on the jointer mainly and then during the projects if needed.

I have the milwaukee 4" as well, however mine is now true lol .. I do have some of the bigger woodpecker squares that I use so maybe I am partial to them.

If I was you, I would more than likely be looking hard into the 6/8 combo ... more chances to use them over the bigger 12, or the even bigger 18/24 ones or whatever those sizes are ... just my thoughts

I will say I have never used the igaging so I cant comment on quality or anything.

-

5 hours ago, Coop said:

Just curious as to why you will be screwing it to the wall? I realize this can’t be useful to him for too many as he will outgrow it but I would add some drawers to hold his art supplies, big chief tablets, etc. for the next few grades of school.

Mainly in case he decides to climb on it and jump off ... making sure it wouldnt flip. He is almost 6 yo so he still does a lot of not so smart things in his room alone haha

5 hours ago, Kev said:What I did for my kid's desk is similar, I put a stretcher high across the back as well as near the bottom. I didn't secure either to the wall. This secures the back very well but, does nothing for the front corners. My kid's desk had independent legs so, I added this lower rail on the sides as well. For what it's worth, I didn't have any racking issues but, my son was a teen when I built it so, it was just homework and computer stuff and not the stuff a younger child may do.

If you put a stretcher across the front, the height becomes an issue to get a standard chair under it so, this is tricky! It's compounded if you decide to put a drawer there. Additionally, the lower front corners are still a liability if they get knocked hard. Plus, your son is going to go through a lot of physical changes as he grows and I'm sure you'd like this to be a long term desk for him.

Another consideration, if you're really concerned with racking, is to add an x brace in the middle of the legs.

Overall, I think your design is solid enough for a desk but, would add the lower stretcher in the back. Think about the placement of it! Should be high enough to be above floor trim but, low enough to not interfere with any wall outlets.

what if the front stretcher is oriented horizontal instead of vertical? That way it shouldnt really effect the height since its only taking like 3/4-1" or so ... not sure how good that would actually look, but I think I could set it back a few inches so it isnt super noticeable ??

I think a lower stretcher on the back would help stiffen things up quite a bit too. Will add that in ..

Now, one question I wanted to pick yalls brains on ... the top is coming from 6/4 white oak, so final dimension hopefully 1 - 1 1/4" thick ... would it look weird if the legs were 3/4? or should they be the same thickness roughly as the top? Not sure if that would make everything too bulky looking or silly if you have skinny legs ...

-

1 hour ago, Kev said:

1. You could get away with that combo. Especially considering it's a personal choice

2. This may depend on your choice of joinery. M&T would drive you to the choice on the right IMO. Something to consider here is racking. Especially with a young boy, he's probably going to crawl all over this thing..🤣

Shows up in this post but, not the original

Yes, I was thinking about racking ... It will have 1 brace between the legs on the back side ... mainly so I can screw this to the wall. Was not sure if that would be enough or if I need something on the front as well?

5 minutes ago, Coop said:I think the white oak would look ok with the walnut although maple would look better imo. Something to think about on your leg choice is the type of floor it will sit on. Hardwood or carpet is ok, tile, maybe not. Your second option where the end grain of the horizontal piece is covered by the vertical leg would look better. I’m like Kev on the racking. May aprons to secure the legs to each other.

it will be in his bedroom on carpet ...

gave my thoughts on racking above ... what ya think?

-

4 minutes ago, Kev said:

They very first picture isn't showing up

does it show up now?? I added it below here:

-

Just now, Kev said:

Picture isn't showing up for me.. Anyone else having this issue or is it just me?

I think the issue was on my end ... try again?

My Boys Desk

in Member Project Journals

Posted

Haha! Ya just a little bit of a progression from coding your own gcode 😄

you can always download the free version of fusion 360 and play around drawing and stuff on there. Took me about a couple weeks and quite a few YouTube videos to get the basics. But now it’s not too bad and I can build mostly what I need to now