Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,605 -

Joined

-

Last visited

-

Days Won

98

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Posts posted by Bushwacked

-

-

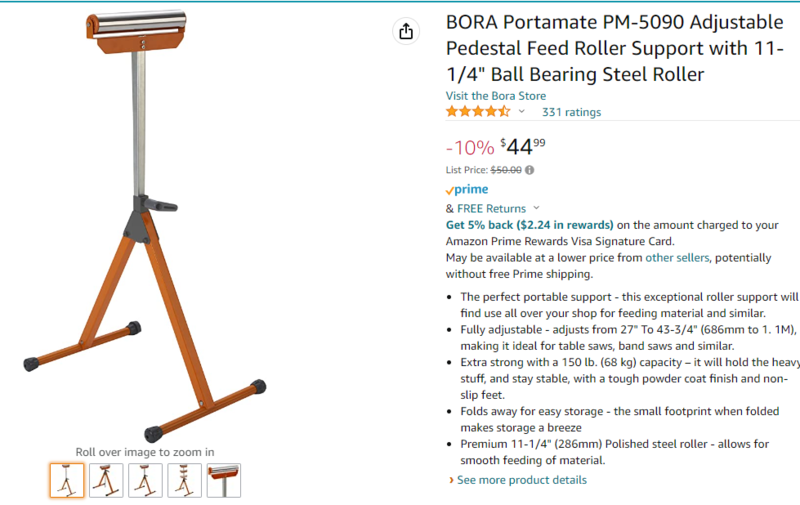

So the stands showed up at like 4pm yesterday and it was 106* so I didn’t feel like doing anything but getting them setup and ready for today or tomorrow when I get time to get out there.

it’s a nice tight squeeze for sure haha. Although the Bora stands were easy to put together and the roller seems to work well. I guess we will see soon how helpful they are…

-

2

2

-

-

11 hours ago, Coop said:

It probably goes without saying but I treat the mortises and tenons on the bb and table top just like any other. Cut the mortises first, dead center and then cut the tenons to fit.

thanks for that ... first time doing any M&T work haha

-

1

1

-

-

started to mill today, found out 9' boards suck to run on a joiner without support, so I bought 2 Bora support rollers that will be here Saturday and I can continue.

16 hours ago, Woodenskye (Bryan) said:3-4” would be fine, if you wanted to go 5” fine but that starts to be a PITA doing that much chisel work. I am not sure how thick your top is going to be, but I always wondered if you could use dowels, if no domino xl for the BB ends. In the middle you do a 3/8 dowel into a 3/8” hole. Then on the outside you do a little larger hole (1/2” or 5/8”). If this actually worked, then you could do a larger BB end, cause you should be able to find a bit that could drill deep enough and not have the chiseling of the mortise.

the top will be as close to 8/4 thick as I can get it ... looking at pictures, I guess yall are right, smaller BB's isnt a bad thing. I always just thought they were roughly the same widths as the main piece to keep symmetry and stuff.

8 hours ago, Kev said:You could get away with the width you're looking at with the Domino XL but, not the 500. I believe rethinking the size of your BBs is the way to go regardless.

I don't think the smaller breadboards would look "funny" at all. Perhaps some image searches would confirm that. I also think the C channel is a viable option is you don't like the look of the smaller BBs.

Do you need them? Maybe, they do serve a purpose. Often times with DF, the dry times are hurried so the MC is a bit higher than normal hard wood lumber. I really think DF is more prone to twisting and cupping than standard hard woods.

I think the dowels could work. The difficult part would be the pins, your holes would have to be spot on. I would also be a little concerned about the strength of the dowels at the pinning point. I'm also not sure that not pinning them would be an option?

You are right ... BB's dont look terrible being smaller. I just had some vision in my mind that wasnt correct haha.

So, now that I got over that mental hurdle of massive BB's, what size should I be looking at for a 9' table? would it be 4" or what? 4" seems like a happy medium ... thoughts?

-

28 minutes ago, Coop said:

I’ve made a few in the past and will be making them in my current project. As a refresher, I took a look at several on YouTube and found this one by Marc. Stumpy Nubs also has one that I can’t locate right now with one eye ( had surgery on the other one yesterday).

https://m.youtube.com/watch?v=TFn7JZmyFqk

hmmm he says its best to go into the breadboard about 1/2 to 2/3's the width ... that would be a really deep mortise if I used the 7" breadboards haha. I guess I could dry a drill press and chisel though?? Would hate to screw that up somehow doing it that way.

Would smaller breadboards, like 3-4" or so look funny on a 9' table? The main table would have about 7 1/2 - 7 3/4 boards for that ... will know once I mill them but they all look mainly good and are all about 8" wide.

If they would look goofy, does this table even need them? Maybe C channel would be a better approach? or since it is vertical grain doug fir, it wont be moving too crazy since all the grain is the same and just a normal put together table would work?

-

something like this?

-

40 minutes ago, Kev said:

That's a wide BB but, not undoable.. There's a few things to think through when determining how big the tenon needs to be. The biggest thing to think about is the depth of the mortise. If you decide to make them 3", do you have the tooling to reach that depth? I think that would be pushing my limits pretty good. Now, at 6" BBs with 2" M&T, those are numbers I could comfortably hit.

I don't know that there's any magic formula to it to be honest.

Another option would be the large domino as well. Keeping a pair of center dominos on the tight setting and all the outside ones on the loose setting would work perfectly. Of course, not everyone has this tool in their arsenal..

hah! yep I have no idea what I am doing with them 🙂 I guess if I do not use my domino, then I might need to rethink how big the ends need to be ... For the domino, would I glue everything like normal though with the tight setting on the middle and loose on the outside? or what?

-

13 hours ago, Woodenskye (Bryan) said:

Ci think 23” would be tippy. If you take your 40” and did 6” as a maximum overhang on both sides that would leave you at 28”.

Thanks!

question on breadboard ends … never done them before so they are one of a couple new challenges I wanted for this project … if my breadboard is probably coming out at around 7 1/2” wide … how deep should my tenons going into that?

-

Looking at table legs and ideas with the wife ... would 23" wide legs be too short for a table about 40" or so wide? Trying to figure out if it would be tippy

-

happy 4th to you too!!

Hopefully you got a good burger or steak somewhere 🙂

-

1

1

-

-

On 7/2/2022 at 12:55 PM, Jamie said:

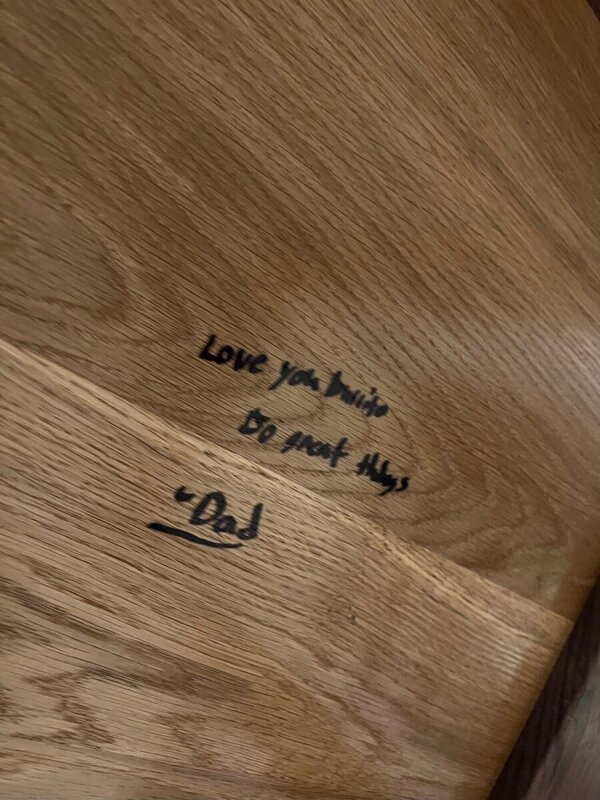

That is amazing! Great work! That will last him a lifetime.

thanks! hoping so!!

-

20 hours ago, Coop said:

BW, unless you have already purchased the wood, I would go with cypress. It is a pleasure to work with and I have been using it to build my Purple Martin houses and Adirondack chairs for years.

the problem was I couldnt find anything that showed nice grain for the cypress ... mostly all I could find was the fancier sinker/pecky cypress and then slabs. So she never got a real good visual of what it would look like.

Douglas fir she did enjoy the nice quarter sawn/vertical grain of it.

-

1

1

-

-

1 hour ago, Jamie said:

I built a whole house full of cabinets with qs doug fir. Turned out awesome! Was a pain to get it to take stain evenly tho. One other thing with the doug fir is the slivers burn like nothing you have ever had before.

Good to hear 😄

glad I won’t be staining though as that sounds horrible not taking stain evenly.

oh wonderful, guess I’ll just start crying now in preparation of the splinters 🤣

-

1

1

-

-

Talking with the wife … I might be going quarter sawn Douglas fir. I know it’s on the softer end but great outdoor use.

this project will be kicking off probably next week.

-

3

3

-

-

11 hours ago, Coop said:

BW, I forget, does the outside box house a dc canister? Theater cnc is a neat deal!

no, just a straight pipe down with nothing .. still waiting on Kev to test his sound dampener out 😉 , that would be the only thing I would add to it. I dont mind the dust, a quick water/mow will get rid of most of it.

-

-

looking good! Looks like the doors fit well, I hate doing doors I have the worst luck with something not being right and throwing it all off haha.

-

1

1

-

-

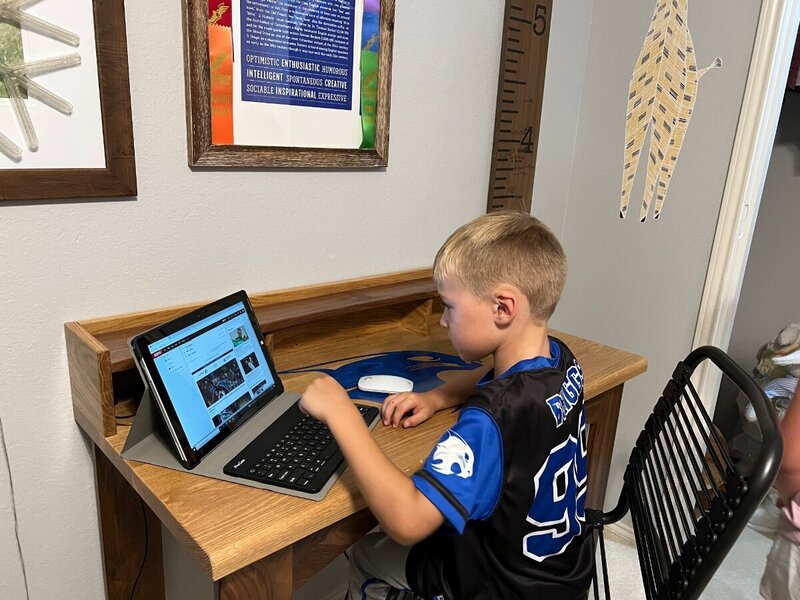

-

13 hours ago, Kev said:

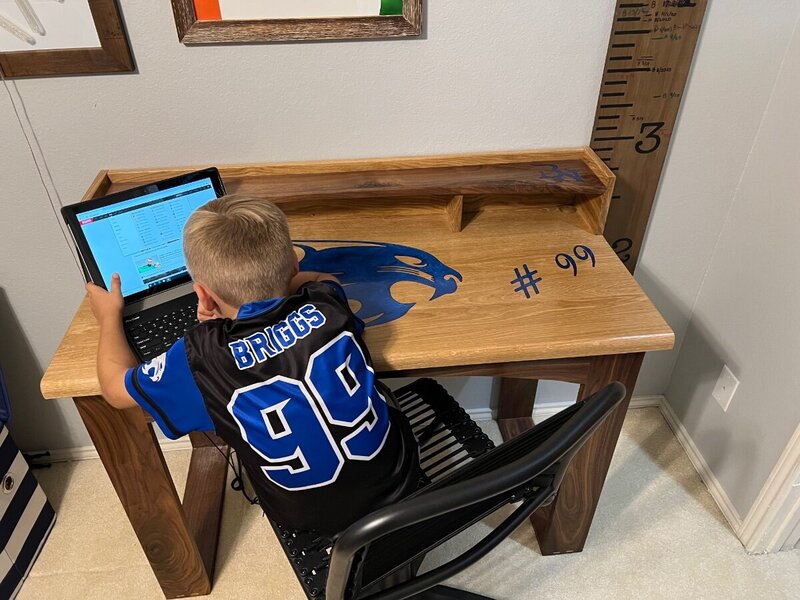

Pretty awesome!

I'm sure he'll get many many years of use out of that desk!

thanks! I am hoping this lasts him until college, or until he wants to build his own haha

8 hours ago, Coop said:That is really cool! You did a great job!

thank you! I surprised myself with this one and how well it turned out ... almost makes me want to rethink my desk and build another one 🙂

-

1

1

-

-

-

-

-

The first coat. I think the epoxy looks great and the yellowish white oak seems like a great contrast to the walnut.

1 down, like 3ish more to go ... we shall see

-

2

2

-

-

2 hours ago, Coop said:

Spraying shellac can wear you out. By the time you finish multiple pieces, it’s time to sand and re-coat.

Hah! No kidding!! This texas heat doesnt make me wait long before a new coat. I guess its a blessing and a curse haha

-

2 hours ago, Kev said:

Looking sharp!

thanks! really happy with how the shellac looks on there ... and super easy to spray/cleanup too in the gun.

Outdoor Dining Table

in Member Project Journals

Posted

So far seems very clear!