Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,605 -

Joined

-

Last visited

-

Days Won

98

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Posts posted by Bushwacked

-

-

Well… he was cutting logs down for table center pieces for his wedding and it caught something and pulled up the log into the machine and bent the blade guide and like 3 teeth on the blade. luckily his fingers were not dragged into the blade.

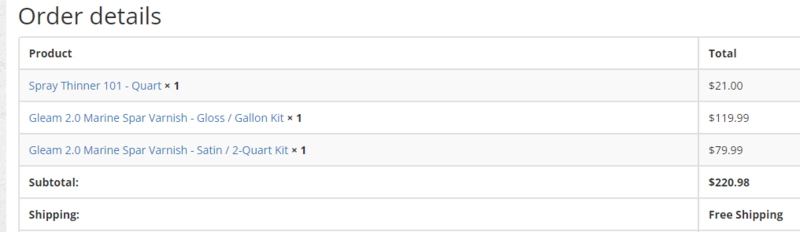

Waiting to hear back on the new blade tomorrow .. but the guide price ..

-

1 hour ago, Coop said:

Or you could drill from the bottom, thru your bb and halfway into the top and hide the dowels completely. As most dowels are end grain showing and I find that end grain seems to absorb water more easily, going from underneath might also give them protection from the elements.

hmmm ... thats not a bad thought there coop ... I will definitely give that some thought. All hidden would look nice

-

11 hours ago, Coop said:

I think you’re good for sure! So you decided to use dowels, eh? I haven’t seen a video on using those. How do you treat the wood movement concern?

Ooops, after zooming in, I see the marks for the wood removal/tenons. You’re talking about the dowel from below. I saw the red line and thought you were going to dowel from the end. You’re still good with location or you could move over a tad if you’re concerned. Dead center is not absolute.haha, yes dowels through the top, I am not sure if I want to try and hide the end dowels from the bottom yet ... I think 1 dowel would just look strange so I dont mind seeing the 3 on the top.

1 hour ago, Kev said:You should be fine with the dowel in there. The seam is glued up tight and this dowel will also get glued in solid. The others will float a little side to side and would be more concerning than the middle one.

Glad to hear yall dont think putting a down dead center in a glue line will be an issue ... kinda freaked me out a little when I got it all drawn out.

-

Squared up the ends and Started to lay out my tenons and stuff this weekend in the spare few mins I had. Noticed one terrible luck thing right off … dead center is a glue line 🤦♂️ Probably could not have done that again even if I tried haha.

red line is dead center and dead center of the middle tenon on the glue line. Assuming it would be a bad idea to try and put a dowel there?? Or am I overthinking it since it’s all glued and will be glued again??

-

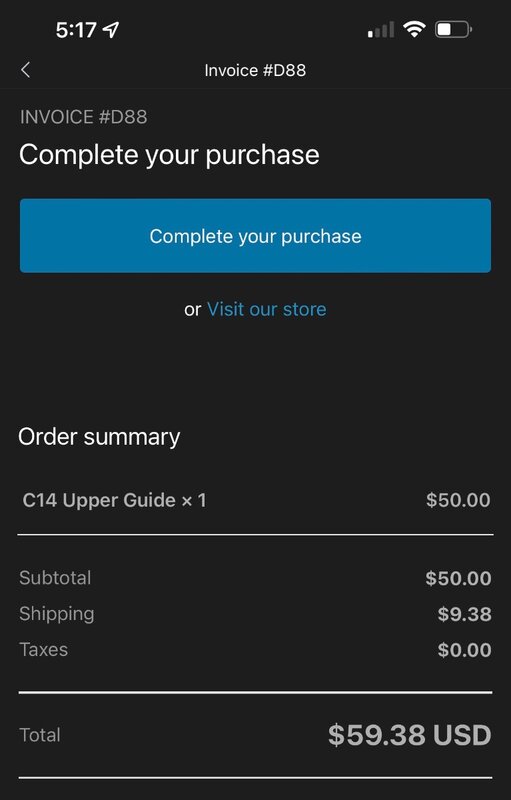

I was talking with a total boat rep and decided to give them a go ... seems like its worth a shot of this outdoor piece. After talking, this is what I went with. They recommended using the gloss to build layers and bring out the colors, then a couple satin coats to bring down the finish. Spray thinner is about 10-20%, plus it can be used to clean the gun after ... not sure if I could have used mineral spirits as well, but I guess for $21 it will be a good test.

Have yall ever used any of these before?

-

1

1

-

-

1 hour ago, Kev said:

Looking awesome!

If this job runs long, I'll be giving away another hand plane while the videos are on Hiatus..

Are you thinking there might be a chance of it running long?

Dang! That is awesome! One of the only people I see giving away real stuff and not just sponsored junk

9 hours ago, Coop said:Looks damn nice! Looking forward to the bb end construction. Just go slow and easy, measure and re-measure and test those on scrap pieces of the same thickness and you should have no problem. Buena Suerte!

thanks!

Hah! Ya, going to watch marks video several times to make sure I am getting everything ... should be interesting 🙂

-

Got the table on supports ..

started trying to clean up the glue lines as well. This sweet number 4 should look familiar Kev 😁 it’s getting a good amount down and looking nice. Still have a few spots that I’ll need to use the glue and sawdust trick though

next will be time to square up the ends and then work on the breadboards.

-

2

2

-

-

1 hour ago, Woodenskye (Bryan) said:

If they are deep gouges, the epoxy May add a bit more strength than just wood glue or filler.

Since you live on the sun you may not get much moisture from the MDF, but I would put some stickers or 2x4’s underneath for air flow, but also some support for the portions hanging off the MDF.

thanks for the info!! Will do

-

Also random question … was thinking about this since it’s so long .. can I leave the table on a 4x4 MDF sheet while I work on it or will that 4x4 section get all out of whack moisture wise and start trying to warp?

was trying to figure out if I need to put it up on some wood to let it get air under there as well while working on it? Most likely will be on this table for a few weeks while I get it finished up.

-

17 hours ago, Woodenskye (Bryan) said:

On the deeper parts you might want to mix sawdust and epoxy, cause your table may become thin belt sanding it even. The other option is grab some chain and beat the hell out of it, that’s what some call rustic!

never used sawdust and epoxy before ... whats different than that and wood glue?

Hah! I might just take a chain to it anyways after all the issues

9 hours ago, Coop said:Is there the same problem with the other side?

yep, both sides where I scraped had some issues tearing out.

Although, the past 2 glue ups, I made sure to try and wipe as much glue as possible off from the top side and that seems to be working a lot better, then its just a sanding to get rid of it.

-

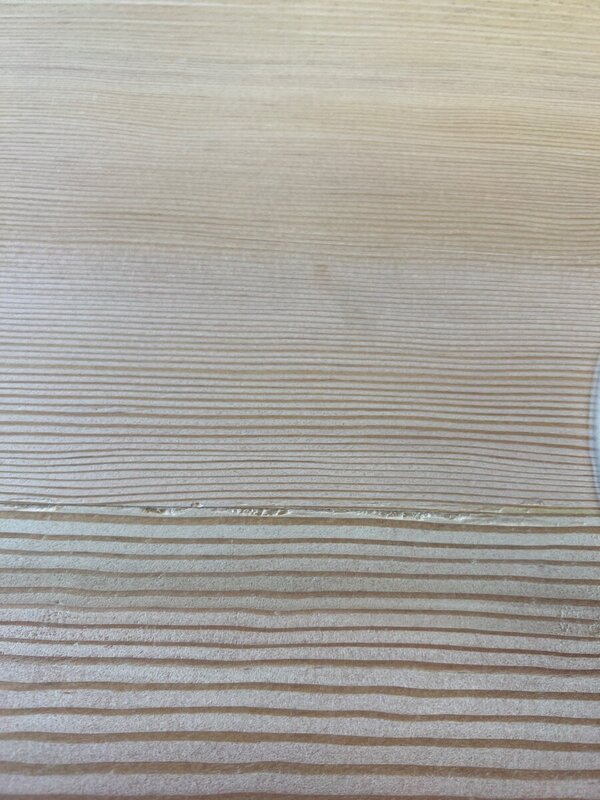

12 hours ago, Coop said:

BW, from the looks of your second pic above, it appears that you are scraping the dried glue off in the direction of the glue run itself and it’s picking up the soft wood fibers. It’s a little more time consuming but make all of your scrapes in the direction of the wood grain. I think you will see little to no tear out.

So the crazy part is .. I was scraping almost always with the grain … sometimes I’d get a little sideways but for the most part it was with the grain down the glue line.

4 hours ago, Kev said:Depending on how deep they are, I would be tempted to just sand them out..

Another option, if you have the width, is to cut it at the seam and reglue.

Ya I’m gonna get the belt sander and pencil and if see if 2-3 rounds gets it all out. Once everything is glued. Just 1 more piece to glue up today …

going to think about ripping them and reg lying today. Gonna do a quick test with the saw dust and glue and see how that goes on a little section. If it sucks I’ll be ripping them

-

1 hour ago, Kev said:

The softer woods definitely compound that issue.. Sanding is probably your best option..

I'm glad I'm not woodworking in those temps!

ya I am learning that haha ..

This glue up I tried to wipe all the glue off, at least on the top so sanding should get rid of that. Not sure what I am going to do about the other messy edges. Might try the glue and saw dust trick maybe ... still trying to figure that out.

-

Got all the doubles glued together. When I was scraping glue off I noticed it was taking wood with it .. so that’s fun. My nice clean edges are kinda janky now …

all 3 completed ..

started the glueup on 2 doubles now.

had to get all the long ones I owned after this glueup.

the garage got warm today and made the glueups interesting… the glue was already drying it loooked like by the time I got to the other end to spread it ..

-

1

1

-

-

1 minute ago, Coop said:

Are they pretty smooth or will you have to run them thru the planer before gluing up the pairs? I forget now how wide each individual board was?

They are pretty smooth. I put dominoes in them to make sure because they are all about 7 to 7 1/2” wide so these can’t go back through the planer.

-

1

1

-

1

1

-

-

Some more work. Let the other glueup dry about 10 hours from this morning. Now going to let this one dry over night. just for you Coop.. I have so many clamps I just sit them around doing nothing 🤣

shimmed them on the floor to keep them somewhat level no idea if that slope and them having like a 1/8” gap at the bottom will have any effect but didn’t want to risk it as they sit there for about half a day to day …

it was only 111* here today but felt like a cold front in the garage at 99* 🥶

-

2

2

-

-

18 hours ago, Coop said:

I think this pic is just a show of clamps! 😁

Are you going to continue to glue two together, then glue two more etc., then start gluing those to each other? Looks like pipe clamps might be in order for the last glue up?

Darn those are some nice looking straight grain boards!haha you caught me Coop!!

Yes, the plan is 3 glueups of 2, then 2 of 2 and then add the last 2 on there. Dont have any pipe clamps so it will be a mix of longer parallel and doubled up parallel smaller ones.

Yes I am really liking these boards, I think it will look sharp once I get them all together.

-

1

1

-

-

-

After a fun filled week of shit breaking down 🤬 … I finally have milled lumber!

first the joiner did it’s thing and then the jack on the mobile stand for tablesaw lost a bolt … so to fix I had to take it completely out and it took hours over a 2 days of frustration to get that right …

all to just turn the saw some to rip the long boards ..

-

10 hours ago, Coop said:

That’s cool. The very last frames with the closeup of the pulls, I don’t see the indention made by the point of the Fortsner bit. Think it was hidden from view by the pull itself? Thanks for sharing.

I was thinking the same, I think the bar is covering it up ??

-

makes sense .. and yes 1% is crazy haha

Thanks for the info though .. I guess I will be letting would hit that 1-2% mark from now on.

-

one of the guys I follow ... no talking, just all working. Some great ideas on jigs and that assembly table looks like a cork top??? maybe its just mdf or something .. also he has some amazing other builds as well, I would recommend checking him out.

-

2

2

-

-

On 7/12/2022 at 6:24 AM, Kev said:

I wouldn't say the meter is broke, it's just not an accurate reading relative to the rest of the lumber.

Pin style meters like this (I have one as well) aren't the most accurate but, that's actually irrelevant. Find a piece of lumber in your shop that's been there for a good long time and check the moisture on that. Then, check your new lumber exactly the same way you checked the "known" lumber from your shop. You're looking for a difference on the meter. It doesn't really matter what the number is. You want the lumber you bring into your shop to be ~ the same as your "known" lumber.

These numbers are your to be different all over the country. It won't take you long to figure out where lumber coming into your shop should be. When I was in WA, I was looking for 11% on my meter. In MT, I'm looking for 7%. When I see those numbers, that's when I know the lumber is ready to go.

Now, normal hardwoods coming from a local dealer don't usually cause any issues and I rarely check them. If I get lumber from a local mill or other unknown source, I'm checking them for sure. In your case, you've got lumber that's usually used for construction so, may not have gone through the proper drying process which could bite you in the butt after the project is built.

Hope that helps and I explained it well.. Just getting off of work and I'm tired. 🤪

does the older lumber I am checking need a fresh cut/plane or anything or can I just jab it? If I can just jab it ... the older stuff was reading 0-1%. I feel this meter is a POS haha

-

13 hours ago, Kev said:

You would expect it to be the driest on the end grain as that's where most of the moisture escapes. When you rough cut one to length, check the cut end the same way and see what you get.. 3% is really low BTW..

Ok I’ll do that .. should have things milled up tomorrow I think. I’ll take a few more readings then.

like good low or so low meter is broke haha

-

@Kevyour moisture comment above got me thinking … no clue if I’m doing it right but it’s about 1/8” jammed into the end grain and held there for like 30 seconds. The others were around the same too. Maybe my supplier doesn’t buy the rushed stuff?

also first whoopsy not paying attention. Wondered why so much Doug fir was outside hahaha 🤣

also today that little fella fell out again. At least this time when it started happening I knew what it was and took about 5 mins to fix

-

2

2

-

Harvey Bandsaw 0 - Brother in law 1

in Power Tools

Posted

nope my wifes brother on my bandsaw ... was running about 10-12" diameter logs through. I was on my way back from my moms so I didnt get to see it.