Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,605 -

Joined

-

Last visited

-

Days Won

98

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Posts posted by Bushwacked

-

-

24 minutes ago, Chet said:

Lastest post from Marc. I appears that the two $20 capacitors from Amazon fixed what Powermatic said would take $1800 dollars to fix.

not a good look for PM ...

-

dang that is crazy!! how would they not just sell that part. a whole new motor seems outrageous at 1800 for a $20 part. Definitely not the gold standard anymore. Hoping my PM 8" joiner holds up though lol

-

-

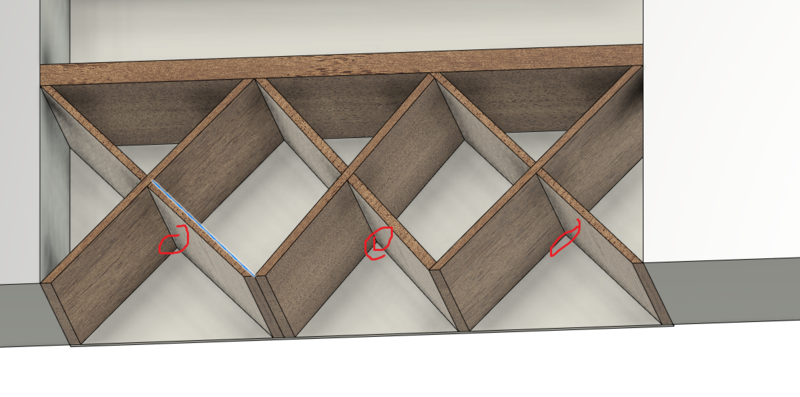

2 hours ago, Kev said:

I too think 1/2 lap would be the way to go ultimately. Especially if you could add some small corner blocks to reinforce the joint.

I also think you could get away with some shallow dados assuming this is solid wood and not trimmed ply.

What's the purpose of this section? You see this a lot with wine storage which could accumulate some weight.

ya laps seem to be the way to go ... what do you mean some small corner blocks?

hah! it will be trimmer ply to save some money for them.

It will actually hold those like 12x4x4 (or close) fire starter logs for them. So they might weigh just as much as wine or even more stacked in there??

-

1 hour ago, Chet said:

I just did something similar, not 16 inches deep but it was deeper than I could get of my table saw. I did it on my router table. My material was 3/4" thick and I used a 1/2" diameter bit to make my cuts. By using the 1/2" bit it allowed me to flip the pieces, not only to sneak up on the fit but also keep the cut centered. I used a stop block on my fence for depth of cut. Then chiseled to square up the cuts. I did a full size test with some poplar to get everything dialed in. When you hit the stop block, hold the piece securely and turn off the router DON'T try backing it out with the router running.

oh good idea too! curious, the panels will be plywood with hardwood face, can you chisel plywood with good results? never tried to chisel plywood before haha

-

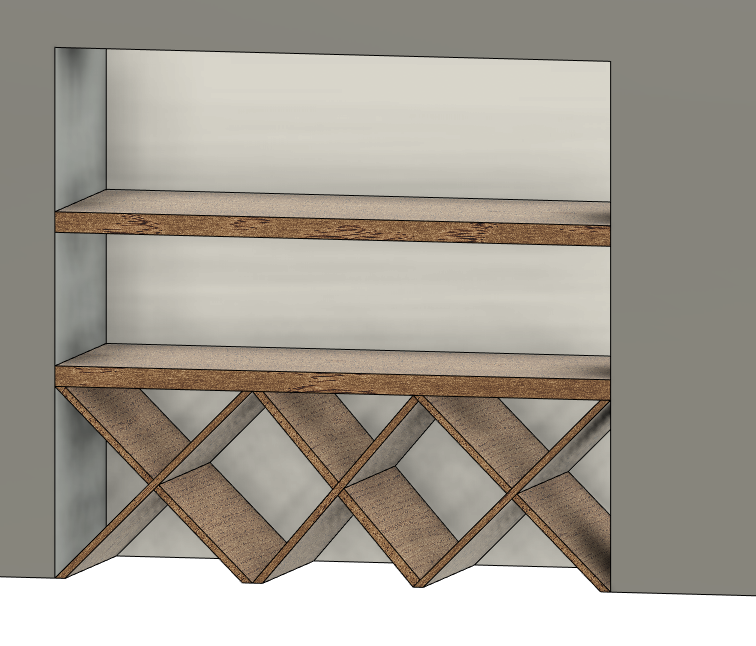

So I have a customer build (potentially, waiting on acceptance of quote), but have been tossing around ideas on how to cut the X section, but still not sold on 100% I like any of the ideas.

So I am curious about the bottom X's ... they are 16" deep, so thats part of the problem. I was thinking lap joints but being so deep that would be a big lap joint and I would need to cut on the bandsaw. Not sure how clean that would look coming from that ?? Although this is still my #1 idea so far.

Next thought was to just cut 1 side in half and then domino 2 sides pieces into that, but that could be way more effort and tricky alignment than needed.

Also, the other thing I wasnt sure of, should I build these 3 X's as 3 separate pieces and just sit them in there and then glue down to install? Not sure one big piece would be any better?

-

good tip, thanks for that .. will keep it in mind if it starts feeling sluggish

-

15 hours ago, Kev said:

You'll be super happy with that set up bud! @Chethas something very similar and it's super nice! Probably the best fence in the game!

Enjoy!

I have been binge watching videos on it, it seems so simple to use too once you get the hang of the basics. Plus all the dove tail /box joint setups ... its like this should have been what the leigh DT jig should have been. Not a 2 hour study session every time I want to use it lol

-

1

1

-

-

A guy that works for my wife is getting out of woodworking and this was his last big tool to sell. New (to me) tool day!!! the whole thing cost me $1k even. Now I gotta binge YouTube and start reading the books to figure out how to use it haha.

Came with the porter cable router

and the biggest reference guide book I’ve ever seen haha this thing is legit like 18” tall

-

2

2

-

-

1 hour ago, Chet said:

I came real close to buying a couple of sets of those, but ended up just making some. How much were they? If I remember correctly they weren't that much.

paid $22 shipped while they were on sale, but now looks to be back up to $37ish

-

-

5 hours ago, Kev said:

I have a few different stops that I've tried over the years..

- Rockler Flip Stop - Had to be adapted to fit the rails at my miter station - This one is still in the shop since it works.

- Katz Moses - Not a flip stop and didn't adjust to the bottom of my rails so thin material would pass under - I rarely use these.

- Home made stops - again, not flip so, had to be constantly removed - Most of these have been relegated to jigs and fixtures.

- A couple different Chinese knock offs that are all broken and gone - cheap garbage

curious how you liked the Katz Moses and why you rarely use it? I hear good things about it, but never bought one

-

3 hours ago, Kev said:

Are those specific to your machine or is it something you could have found locally?

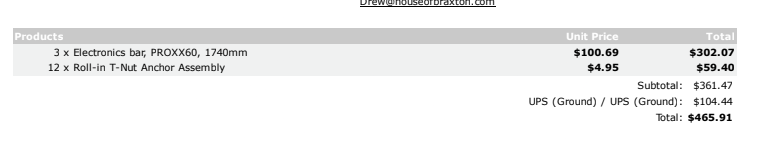

I wouldnt say specific ... but I couldnt find anything local that was cheap enough to make it worth the drive vs shipping. Nearest place was about 45 mins / hour away and I would have saved about $50 minus gas/time plus I would have had to cut the pieces or have them cut for extra $$

-

1

1

-

-

ordered my supports for the CnC to hopefully get that storage build going in 4-6 weeks ... shipping long extrusions suuuuuucks!!!

-

1

1

-

-

7 minutes ago, Chet said:

I know people with think I am nuts, but I am pretty happy with my total setup, I don't want for much. 😊

I mean ... is this even English? I don't understand

-

1

1

-

-

6 hours ago, Chet said:

Nope, I just wouldn't use it enough to justify having a specialized tool like that.

that should never stop you from buying

-

40 minutes ago, Chet said:

Looks like heavy duty pro equipment, something that gets used all day everyday. Having a miter saw with a 3 or 4 HP motor in a hobbyist shop is just being able to say you have one. 🤪

Sounds like Kev needs to upgrade

-

1

1

-

-

wow!! never heard of them and not sure who actually uses them. Definitely pricey for sure!

-

1

1

-

-

instead of tons of typing ... I have watches this guys for a long time. Great info on lasers and setups and the reviews ...

I do not own one yet, but definitely something I am interested in for sure and have been for awhile.

-

1

1

-

-

3 hours ago, Muttley000 said:

Sadly I have fallen way behind on my video watching but this is one of my favorite channels, and he only lives an hour from me. Jeff Fischer also has a short video on one he built. Would be an awesome addition for sure!

nice build there too ... curious how he made the table part .. looked at another video and unless I missed it, he didnt say or quickly said while I was skipping around haha

-

This is a wild build here! Great idea to save a bit of money, if you have the space ...

-

Speaking of panel vs crosscut .. y’all see his build?

-

1

1

-

-

Those look great!!

-

1

1

-

-

2 hours ago, Kev said:

Panel sleds are fairly good sized as well. They're just not as limiting as a traditional cross cut sled.

I'll admit, my preconceived thoughts on this topic was that most would be using traditional cross cut sleds. I was a little surprised by the first answer out of the box!

True, they are and mine is … just meant storing 2 big sleds is tough in a smaller shop.

My ugly beast of a panel sled .. beat up good for sure and still cutting square

-

1

1

-

Ideas on best way to make this?

in General Discussion

Posted

tossed around this idea too ..