Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

6,303 -

Joined

-

Last visited

-

Days Won

575

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Everything posted by Kev

-

Ok.. I just thought of one more option and it's a little unique! Cut the corner off and replace it with a repair piece that's big enough to sign the piece. Call it your signature corner.

-

That would depend on the saw.. I actually use mine for finished ends so, I would still have a MS even in a small shop. The footprint would be significantly different for sure though! The MS is probably my most frequently used tool in the shop. Just different work flows and neither is wrong.

-

Ah.. Ok.. Now it's in context.. African Mahogany. .. Sheet is due here tomorrow.

-

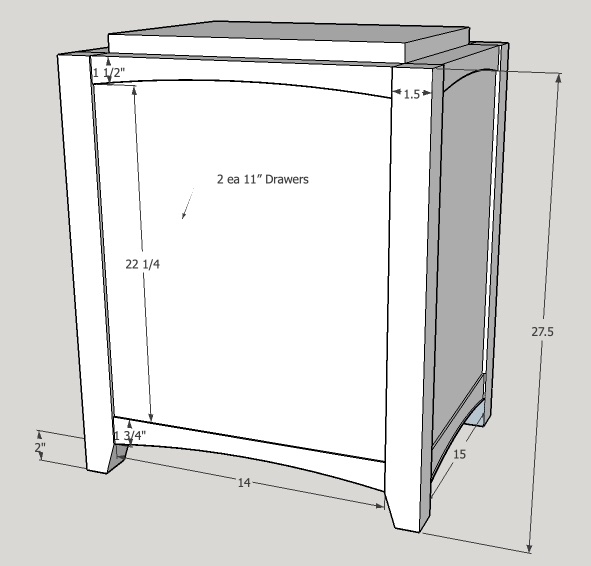

The rails are a little different size as a design choice and, it also bought me a little needed room to fit the 2 file drawers. The under mount glides (Blum) are typically mounted to the sides. The middle set in this cabinet will be unsupported on the bottom but, I'm not expecting anywhere near the weight load for these glides. I chose the under mount for drawer size considerations. With side glides, you lose 1" to the width of the drawer and keep them at full depth. With under mount glides, you lose 1/2" to the depth of the drawer but, keep the full width. And, the Blums have a lot more adjustment options as well as they just function better. Over all, they're just a better glide but, their price point goes right along with being a better glide.. I'm not sure where you saw AM ply? I reread my last post but, I've obviously missed something somewhere.. Not that that is anything new...lol

-

We'll agree to disagree on the miter saw but, I definitely missed the jig saw! I also missed a track saw..

-

Posting this for the group as I'd like to eventually consolidate the conversations here and move them to the reference section as this is a fairly common question. Assume I'm brand new to woodworking and I plan on sticking with the hobby. What big tools do I need and in what order should they come? Also, in a second list, what smaller tools do I need and in what order? I'll start with my list but, reserve the right to change my order and add to the list....lol Shop Equipment: Table Saw Planer Jointer Dust Collection Bandsaw Miter Saw Router Table Drill Press Drum Sander Protable Tools: Clamps Cordless drill / bits Router / Basic bits Sander Jig Saw Chisels/mallet Sharpening system Block Plane Hand Saw - Rip and Crosscut Router Plane Low Angle Jack plane Track Saw Other Essential Items: Accurate square marking knife Bench - Useable with vises Shop consumables - Glue, finishes, sandpaper, etc..

-

Got some work in on the dest the last couple days! I forgot to get pictures last night so, didn't post the progress.. This picture is of the file cabinet side of the desk but, both cabinets are being worked at the same time. So, they're both at the same stage... All the rails are finished sanded to 180 with all the appropriate grooves for the panels and the curves. It's also dry fit so, the joinery is done as well.. Next up will be grooving the legs for the panels which I'll get to tomorrow.. My ply won't be here until tomorrow anyway so, there's really no reason to rush along.. For the top, I'm going to recess 1/2" ply inside after notching the legs. I'll add an additional support or 2 across the top using pocket screws as you'll never see them and they're only there for support. The bottom will be a piece of BB in a thickness that I have on hand.. It's only there as a dust stop so, the thickness isn't really that important. The under mount glides will be mounted to the sides after fillers are installed ..

-

Just tossing out an option... Epoxy the corner using some yellow/brown transtint dye. Another option would be to trim 1/16" off of each side and create a border around the entire piece. Turn the flaw into a feature with some thin ebony or Padauk to look like you planned it.. Ebony is expensive so, maybe Wenge is a better option there...

-

This is a fair point and I often see people put things like this off for cost reasons. Just another thought to consider... Have you ever seen a product go down in price other than a sale? I completely get it! We can't afford everything we want when we want it! Family is all of our first priority as it should be. I guess my point is to decide where a particular item is on your shop priority list.. I know I have a list and I tackle those items on the list as money becomes available. I really try not wait because waiting usually costs more money down the line. I also move the more expensive items further up my priority list because the price changes on those items tend to hurt a little worse..lol

-

Yea, I can still get them where I live.. Maybe I should add them to my store....lol. For the record... Brown wrapping paper is exactly the same thing..

-

2 coats of ARS followed up with 4 coats of lacquer. Sanded with 400 between coats and final rubbed with a paper bag.

-

No.. I've actually got a lot done already! Nearly complete with the 0 clearance fence for the Harvey - I have the prototype installed on the miter gauge. The knife is done and will be shipped tomorrow I did one of Marc's headphone holders for my son - I also made the template so that I can make more And, all the base parts are milled up for the 2 base cabinets for the desk.. Joinery tomorrow - And, the additional lumber that I was short is ordered.

-

Nope.. Word to the wise.. Use a lot of blue tape to tape up the blade while working the handle.. They are sharp!

-

Needed to get a quick gift out so, went back to the knives.. A little different blank this time that I kind of like! Bubinga for the handle..

-

Nice! Sounds like the hard work paid off!

-

I had originally designed for 2" legs but, I needed to buy some real-estate from a few different places to make everything work. I'm hoping they don't look "spindly" and I'm sure my wife will let me know if they do....lol I roughed out the legs from some material I picked up this morning.. The board that I pulled all these legs from was just a little over 5" wide but, I could pull all the legs for both cabinets from one board with 2 spare legs. What really surprised me was the amount of reaction wood in such a small board. There wasn't a lot of twist or cup to the board in its full length - About 10'. I cut them into 30" chunks and milled everything flat and square. From there, I ripped the individual legs out leaving them oversized and I'm glad I did! Here's a picture of them before I stickered them for the night to do whatever else they were going to do..

-

Maybe side to side, I'm not sure..

-

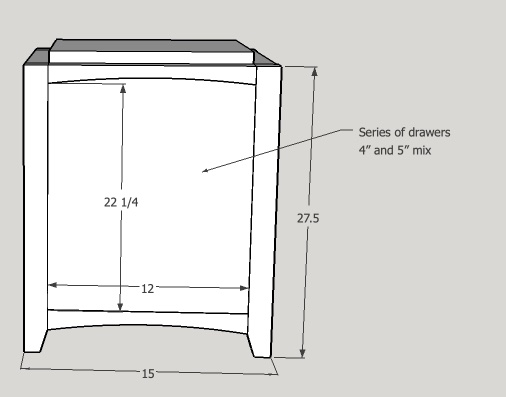

Back to this design today.. Once I was able to get some actual measurements, I think I'm going to be ok.. I'll be able to get 2 file drawers into this design but, there won't be any web frames in the case. I'll be side mounting the Blum under mount glides. Now, where this design threw me a curve ball was on the smaller cabinet! If I stayed with my original footprint, I'd of had a bank of 7" wide drawers.. Yes, those are about useless...lol. So, I expanded that case to get 12" drawers. I'm just hoping it's not a knee knocker! I'll build the 2 cases first and then lay it all out on the floor to see if I need to adjust the size of the top on that side.. Fortunately, I have some room on that side so, I can make that adjustment. I know I have enough material on hand to get going. I have the 8/4 for the top on order (looking for 6/4 when flat) as well as a sheet of 1/2" AM ply for the case sides.

-

The handle actually hangs below the top of the bench and fits the t-track perfectly. I don't think it would interfere with the refrigerator, it doesn't hang that low. The temporary solution for it will probably be adding a block under it so that the handle clears the bench top and then just pushing it back out of the way. I end up with long pieces at the miter saw far more than I actually use the HCM..

-

I probably could.. I'd have a little concern with the cart becoming "tippy" in that scenario though..

-

That couldn't be further from reality!!! When I designed this shop, I had some additions that I thought I wanted in the future and couldn't find legitimate room for them. So, the thought process drifted towards "I didn't need them before, why would I need then now".... Well, now it's the future.. There's some things that I'd like to have but, haven't accounted room for.. Things like a shaper and a CNC are not in my plans because of my lack of space. This sander was on my list but, I thought it would be on a cart to use when needed or, another piece of equipment less frequently used would be on a mobile cart to make room. Same thought with the HCM.. At this point, I'm more concerned with enough floor space to build larger projects than I am adding a shaper or a CNC! I can get away with things used infrequently and rolled out when needed. I've considered adding in Incra fence to my router table. They're awesome but, would chew up some of that floor space to pull it off.. Am I willing to give up that floor space? Time will tell...

-

Yea, the 1/4-20 square nuts are about 1/16" too big.. They're super close though which is why I think you're correct with the metric option.. I'm not in the shop so, don't want to state incorrect info.. There's an SAE option but, it's also not a square nut, it's a regular hex nut.... This is what's currently mounted no my Harvey miter jig..

-

Thanks @Chet! I'm hoping to have the SAE and Metric options later this week! These are too big...

-

Luberderm makes good stuff.. Suggesting more man glitter though ?