Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

2,280 -

Joined

-

Last visited

-

Days Won

93

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Everything posted by Chet

-

I was thinking about this but I have never used it. Do you put it on the screw, screw it in and hope that you get everything adjusted before the loc-tite sets up?

-

No problem. I am not talking about the silver plate in the center I am speaking to the black plate. If you look at the first picture you can make out the set screws around the boarder. In the picture there are three toward the top of the picture and three at the bottom and then there are two each on the left and right side.

-

The metal plate of the lift sits in a rabbet in the MDF top. The metal plate is threaded and that is were the set screws are. To get the plate flush with the top you screw them down to raise the plate and lift assemble, you screw them up to lower the the plate and lift assembly. Incra puts metal discs in the rabbet were the set screws come in contact with the rabbet so there is no wear at contact points. And yes it is strange.

-

It is not the bit that is rising it is the whole lift assembly.

-

I try to be tolerant of things people say about CA. I will politely correct them if it is wrong information. I wouldn't mind living other places but my wife is here and I am not going anywhere with out her.

-

California is moving in a positive direction, has been for a couple of months now. Most of the state is open to most everything. Indoor stuff is mostly at 50% some parts are still at 25% but you can do just about anything you want. The recall is a bunch of crap as far as I am concerned. I am not beholding to any political party but this is just sour grapes in my opinion. One party or the other does this about ever two or three terms and it is getting real stupid and causes the state to spend money it doesn't have.

-

Yep. It is the entire plate, so basically the weight or the whole lift, the plate, lift mechanism and router motor.

-

I am having a situation lately were the set screws around the perimeter of the lift that are used to level my router lift in the table are riding down there by raising the lift above the table. The first time I was doing pattern routing and I noticed that the bit itself seemed to be out of balance. I change the bit and re-adjusted the lift to get it flush and there were know further problems. Yesterday I was making some molding pieces with a quarter round bit and had no problems. Today I was using a dovetail bit to cut some dovetail grooves for drawer slides and it happened again. The first piece I ran jumped a little bit, I wasn't paying attention and I did have the grain the wrong direction. After this I removed some of the waste first at the table saw and then went back to the router but over the course of 8 pieces 15 inches long it had raised again. When I adjust the lift I turn the screws to lower the lift and then start flushing the lift with the table by raising it this should leave the set screws under tension so I am puzzled as to what is going on. It is an Incra Master Lift Any ideas are welcome. I am going to contact Incra on Monday but was hoping the group here could solve it before then. There are ten set screws around the perimeter. This is one of the pieces I was working on.

-

Just hope it stays that way, things can change.

-

I know that it takes two or three weeks after your second shot. Also have heard that it isn't a perfect solution there are still chances, so yea, we are still masking up when outside of our house.

-

It might also be interesting to create two tool set ups based on the floor space of a one car garage and a two car garage in the lower two budgets. I think if you are spending in the upper end budgets you are also done with small spaces. Even coming up with budgets can be a challenge because very rarely does a person start in this hobby with a budget. It usually starts with a couple of tools from some other DYI and the the light bulb moment when they realize they enjoyed that process. I built all of our kids bedroom furniture when they were little with a radial arm saw and a hand held router. When I decided to build our kitchen cabinets is when I started to tool up. Would a visual budget scare some off? I guess if they see a budget here on a woodworking forum they already have their foot stuck in the buck

-

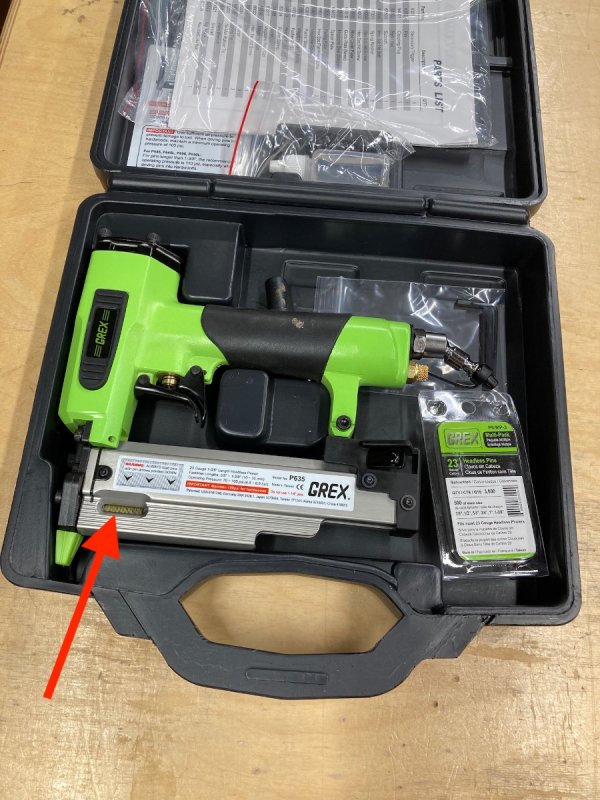

I have never had a pin nailer but I am coming up on my current project were some parts will need a little something to hold things in place while the glue dries. I did a lot of researching and looking some at the reviews. I decided to get one from a company called Metabo. It got some of the best reviews from a number of different places. It was $89 on Amazon and $99 at Lowes. For the amount that I would use it, this was an attractive price. I went ahead and ordered through Amazon and it arrived Tuesday evening. Wednesday morning I gave it a test drive. I looks really well made has a nice balanced feel and is pretty light weight. But as soon as I started to test it there were problems. It wasn't sinking the pins below the surface. They say to set the pressure to between 65 and 100 psi. Well at 70 psi it was leaving 1/8 on an inch on a 1 inch pin sticking out. I adjusted the nose per instructions and nothing changed. After this I kept upping the pressure to 100 psi and it got better but still not right. At 100psi it still left the pin above the surface. Then I noticed that it was leaking oil from around the trigger area. So at this point I wiped it down and packaged it back up and shipped it back for a refund. I was really wanting to like this nailer and thinking and hoping that the leak was causing all the problems, I decided to give it one more try, something I don't usually do. I went to Lowes and picked up a second nailer, got it home tested it out. No Joy, it was better but it was still leaving them proud of the surface so back it went and I moved on. I decided I was going to have to put more money into this purchase and I spent some more time looking on line and a lot of them that I would have gone for are, like a lot of things right now, are on back order. I found a Grex P635 at my Woodcraft store, but still they only had one so I asked if they would hold it until I got there. This is more then I really had hoped to spend, but having used it for just a little while I an happy with the purchase. The price only hurt for a little while and I guess this is one of the cases were you get what you pay for. One thing I noticed right away was it was a lot quieter then the other one. It also has this little window (red arrow) in the side of the magazine that lets you see when you are getting low on pins, I wish my Senco finish and brad nailer had this. So far I am giving it an A.

-

We got our second dose this morning so we should be good to go. I guess know we just need to find out if the vaccine actually works.?

-

I do this a lot, thats why blue tape can end up on my Christmas list. I have probably had more practice. ?

-

-

I am going to color outside the lines a little here. As Bryan mentioned above a lot of newbs start out with a single or half of a double car garage and even then they may have to share the space. I have had this conversation to a point with my nephew, he is real close to this situation. He has a basic non sliding miter saw which I told him is a good way to go because I believe a non sliding MS, unless you get to spending some serious coin, is easier to keep adjusted. He also has a router table. We talked about him getting a bandsaw, track saw and planner along with making a planner sled. This was a plan to get him the most bang for his buck. You can rip with both the track saw and the band saw You can cross cut with the track saw and miter saw You can do your surfacing with the planer and sled You can edge joint with your router and a straight edge, if your router table has a fence that you can off set to out feed side you cn edge joint on your router table. Or you low angle Jack plane. Yea this is all pretty slow compared to having a table saw and jointer added to the above but it also uses up a pretty small foot print in a shared environment.

-

Do you have to put any kind of an edge on the blade with those kits?

-

I lost one spring also. I learned this from somewhere but don't recall who it was, but a ball point pen spring works or in my case a half of a ball point pen spring. It gives you enough tension to allow you to make the adjustment properly.

-

Just spitballing here but I wonder if 1 1/2 inch legs on a case like that will end up looking a little spindly? Just as a comparison my current project has 2 inch legs over all it is 22inches wide 17 inches deep and 29 inches high. You can kind of get a feel for it in the last pic of the journal. I know you are working with some space constraints, just thought I would toss it out there.

-

I would imagine that if you slid the mortiser farther down the track the hand wheel might be in the way of the refrigerator door. But even if you can't slide it down any farther, unless I am missing something, 95% of the time it should work okay there. The one in a hundred chance that you a making a cut on a real long piece you could flip it so the long end goes the other direction couldn't you?

-

This is the one I use Coop. Eucerin Skin Calming

-

Coop I have always had a problem with my hands because of a job that was in a refrigerated area and having to wash my hands all the time. I am going through the same thing again now with washing my hand a lot because of covid. The best one I have found is Eucerin. They have several versions but the best one for me is the one that comes in a tube not a pump dispenser it looks like a big tooth paste tube. One of the pluses to Eucerin is there is no perfume or other odors to it.

-

That was the typo they mentioned in the email.

-

The metric is in the manual Coop, it's M-6.

-

Yea, I had contacted them Coop. The metric size that they listed in in the manual was correct but the SAE size was a typo, but I forget what the correct size was because I had already used the metric so I wasn't concerned enough to remember.