Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

6,314 -

Joined

-

Last visited

-

Days Won

578

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Everything posted by Kev

-

I really shouldn't get a day off when stuck in a hotel room! I ordered a few more things for this table.. Digital height read out, some featherboards, and their new miter gauge.. For the record, I didn't "need" any of it!

-

Super nice @Chet! Really like the sapwood inclusion on the side panel!

-

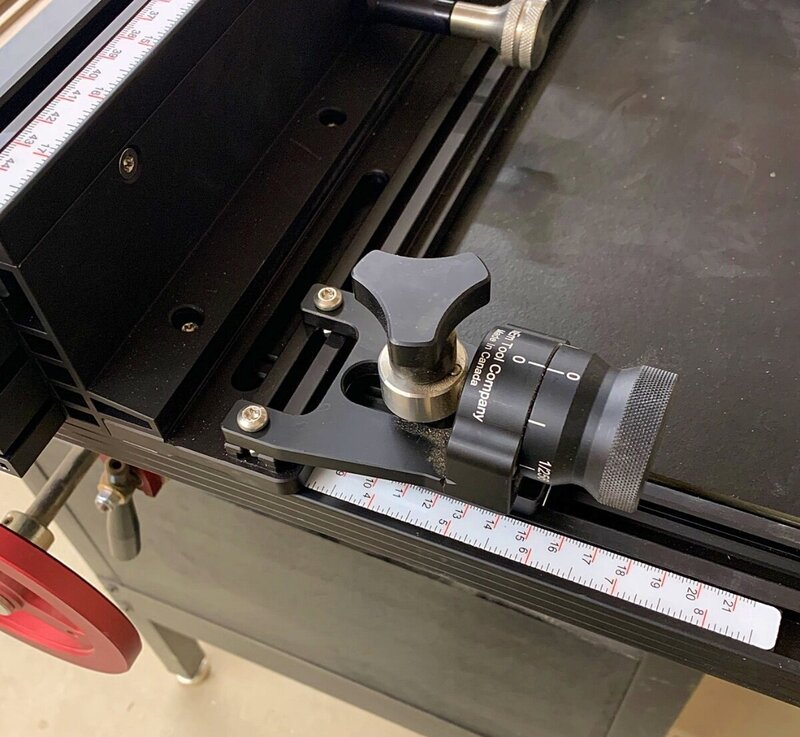

You are correct but, with this set up, that's only really possible with small adjustments. With the fence being parallel and the scales actually locked in, it's much easier to get things really close and then dial it in with the micro adjust. It's a really nice fence but, still doesn't have all the options that the Incra has.

-

I don't use a miter gauge at the router table all that often. I like the micro adjust because it will help me really sneak up on a fit. I do a fair share of sliding dovetails so, the micro adjustment will come in super handy for those. I can also see it coming in handy doing half laps or using panel sets at the router table as well. There's more to come for this table when I get home.. I've ordered a few more things for it to help get things dialed in just right.. Admittedly, none of it is "mandatory" at the router table. Just makes the experience a little nicer.

-

The video for this one is up and available.. Short video but, it was also a really simple install..

-

Just realized that I hadn't moved this to the open area.. Fun project!

-

Nope but, they turned out cool! Nice job! @Ray Martin

-

I think I see what you did, can you post a close up pic?

-

I know that before the prices went crazy, you could buy BB ply cheaper than you could buy the big box store ply so, it might be worth checking.. Last I bought BB locally, it was about 125 a sheet.. I've not used the particular stuff you reference but, I have used refinished ply before for shop projects and it worked fine. Yes, it was a little more prone to warping. Suggest keeping it as flat as possible and get your parts out of it fairly quickly. This will help you store the parts flat which should reduce the tendency to warp.

- 1 reply

-

- 2

-

-

Where's the Festool pull outs? Nice job bud!

-

I think additional Festool storage is a great thought! However, if you're using side glides, those 5" drawers would become 4" drawers. Not really wide enough for useable drawers but, perhaps some taller vertical pullouts might be a better option.. Just depends on what you want to store I suppose. Sorry you didn't get much feedback on this!

-

Ok, probably petty but, just poor craftsmanship bugs the crap out of me.. As you know, I'm traveling for work. The hotel room looks nice and well maintained at first glance. The first shower ruined the curb appeal! My view of the shower tile from the showering position. Off just enough to bug me when standing there.. But, what it did to the other end of the row really bugged me.. You would think they would level the tile and avoid this! Ok.. Vent over..🤣

- 1 reply

-

- 1

-

-

I do this because I enjoy it, I don't want it to be my job. Admittedly, commissions are tough with my work schedule because they have to fit that schedule.

-

Unfortunately, I'm sitting in Ohio right now so, don't have the receipt sitting in front of me but, from memory, I remember it being a little north of $1200.00.. This commission came by word of mouth. I know somebody that works for them and when their normal "woodworker guy" wasn't available to do the work, my name was dropped as an alternative. They looked at my website and YouTube channel and then asked me to do the work.

-

This is another commissioned piece that's been in the works for quite a while. Over the last few months, there's been lots of discussions about what they wanted. I first discussed species options with them and gave them numerous samples of finished lumber to choose from. From there, I presented them with slab options as well as creating the top from multiple boards. Overall dimensions will be 42" x 8' Like most corporations, they're a little slow to make decisions but, they finally decided and I went and picked up the lumber this morning. FAS Walnut and a few of the boards have some really interesting curl to them. They had made the decision to use a custom made steel base some time ago and commissioned that work locally. They're not done yet but, I got them into the shop long enough to make templates for the base mounting. There's still some clean up work and powder coating to be done on them. I'll also be installing 2 C channels in the bottom just to help with twist and warping. All of that hardware is in the shop already. This project will be high on the priority list when I return. I'm sure I'll need @Ray Martin to help me wrestle that walnut through the machines.

-

I did go out this morning and install the micro adjust for the other side of the fence. This is an additional item and doesn't come with the fence. I was hoping to use it on the last fence but, it wouldn't work. So, it's been sitting in the shop for a bit.. I've also ordered a DRO for it and will get that installed when I get home.

-

I did manage to get a little shop time this afternoon and install the new Jessem Router Fence. Looking forward to test driving this one! Install was super easy and only took about 15 minutes. Would be longer if you don't already have a Jessem top but, this unit will mount to other router tables. Pros: Quick Install Micro Adjustability No tools required for operation All metal hardware, no plastic. Cons: Price point. This one just isn't cheap! So, looking forward to getting a few projects in on this when I get home again. I did video it but, it's a pretty short video since everything for me was unbolt old and bolt on new. Oh, the old fence is available if anyone wants it..

-

Looking great! You could do "joinery" just about anyway you'd like. It will only be seen on the top. I guess if I were doing it, I would rabbet the top and bottom to accept the sides and then use glue and screws. You could set the top ones a little deeper and just plug them with some AM if you don't want to see the screw heads. Or, use dowels (or domino) and then you don't have a need for screws. You would need to edge band with some hardwood if you go this route.

-

Video is up and available..

-

Video is now live..

-

I've always found this interesting. Because I always use the dust collection, I've never wanted cordless. The 55 is great and will handle most tasks.. I recently added the 55 to my collection and it's quickly become my go to because it's smaller and lighter.

-

Progress looks good! Cabinets next?

-

This one is finally live!

-

@Ray Martin, I moved this to it's own project. It's looking Great! How did the adjustable shelf work out?