Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

2,280 -

Joined

-

Last visited

-

Days Won

93

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Posts posted by Chet

-

-

58 minutes ago, Kev said:

Are the blades reversable?

good point I'll have to check into that. They are the original Powermatic blade. When the time came to replace them I was going to up grade to a helical head but this is to early I haven't saved enough money to go that route yet.

-

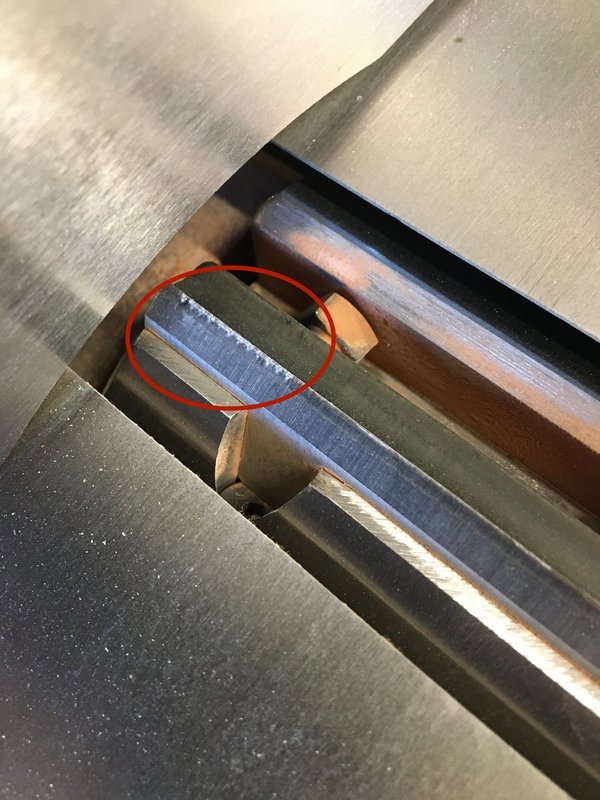

I don't know what happened to my Jointer knives. Last time I used the jointer was when I was building the Morris Chair and I know I would have noticed this then. But the other day I went to edge joint a piece and it looked like I had the blade on a tape dispenser doing the cutting. I have no idea how or when this happened to the knives. It certainly seems like something you would have felt or heard at the time. It's about the first inch of the inside (closest to the fence) part of the blade.

P.S. did I just post the first regular size picture here???

-

submitted on the old forum by bushwacked

I have seen him do this a few times now and thing it’s a pretty cool idea and saves quite a bit of ply too. Sure it seems to take a bit of extra time but the trade seems like a good one. ... if it’s not clear I’m talking about how he uses the braces across all with dados to sit flush with no backs. I I think I’m going to try this on my next shop cabinet build.

-

Submitted on the old forum by terrymck

I use Bosch blades or Piranha (I think the latter are made by Black and Decker) in my jigsaw. But to be honest when breaking down stock by crosscutting I simply use a 22" or 24" hand saw. I have a lot of them and found they are quicker to use, don't jam up or break, don't need any setting up, don't need fancy dust extraction, don't need PPE, don't get kick back and are immediately on hand. When I first saw TWW breaking down stock (on one of his Guild videos) with a jigsaw I thought I would give his method a go but soon reverted back to my traditional method as I wasn't saving any time and found that I spent more time setting up the vac/positioning supports etc.

When breaking down plywood or any other sheet good I use my tracksaw. I also use the tracksaw to apply a straight edge on any stock that is straight off the slab and has a wavy/live edge prior to running on the tablesaw. -

Submitted on the old forum by Kev

I don't really.. I do like the Festool brands that go with the saw but, have no imperial evidence that they're any better than any other blade.

-

submitted on the old forum by Coop

Do you guys use any tind of special jig saw blades?

-

submitted on the old forum by bushwacked

Im curious how much stock is actually getting broken down that a jigsaw is not good.

I can say that I used to use a miter saw ... after having a few discussions with kev and others I have switched to a jigsaw now for rough cuts. I have a perfect gap between my outfeed and tablesaw now that I use for clearance on my blade -

Submitted on the old forum by tmize

I’m a jigsaw user also mainly because I can’t break it down on outfeed table spin around an rip it on the table saw. When I first tried it over my old method it was like a light bulb went off. Why didn’t I ever think of that

-

Submitted on the old forum by Kev

To each his own. Your shop, your flow, your business.

But, if you're in the profession of teaching this stuff, you should probably teach the safe methods if for no other reason than liability. -

Submitted on the old form by Keggers

I guess I'm in the minority here because I have always used my miter saw to break down rough stock with few exceptions. I always clamp down the left side of the board and keep my left hand well out of the way. I'm not suggesting anyone do things my way nor do I plan to defend my practice, but it's worked well for me for the last ten years. I can see the benefit of breaking down boards with a jig saw but with the volume of wood I run through my shop it's not practical for me to do it that way.

-

Submitted on the old forum by Coop

I know and, I really need to quit being so lazy and change my bad and dangerous habits. The last instance I speak of was cutting to rough lengths a 22” wide X 92” long X 2” thick slab of walnut. I also trimmed off a lot of sap wood/bark using the same method. I did it in the yard on the grass and was aware of where my right leg was at all times.

-

Submitted on the old forum by Kev

I don't see a circular saw as the same in this instance as the miter saw. With the miter saw, your off hand is usually supporting the work then therefor vulnerable to being in the line of fire if manure hits the oscillator.

-

Submitted on the old forum by Coop

I’m sure the hammers going to come down on this one but, on most pieces, large and small widths, I use the circ saw. Don’t tell your son! On thicker pieces, I make multiple passes with the correct support and am always cautious of kickback. I have a miter saw but no miter saw station. I use my ms for multiple cuts and for trim.

-

Submitted on the old forum by Kev

I do know that I had a great conversation with my son on this topic.. Was glad to know that he was into doing more research on things rather than just believing what you see on YouTube!

Thanks for the input! -

Submitted on the old form by Mel

Jigsaw always for rough breakdown. I don't even own a miter saw

-

Submitted on the old forum by Kev

I'm noticing a lot more people (many well known YT creators) cutting rough widths on large stock at the miter saw. Of course they would edit out any mistakes, right? I've alway been taught that it's best to do this with a jig saw for safety reasons. And, yes, I've taken this shortcut in the past and had the saw "jump" on me..

Is this people just being lazy or am I missing something?

I currently have my youngest son in the shop for a few days (project for him) and we had some large stock to break down. Since my "teaching" hat is on, I have him cutting to rough length with the jigsaw and than rough ripping at the band saw.

Thoughts?? -

Submitted on the old forum by Kev

For the record, I do think the fences need to be movable for a multitude of reasons and, I also think they need to be removable for a multitude of reasons.

I guess what I'm really questioning is, is this the proper tool to break down rough stock to rough length? This seems to be the reasoning behind removing the fences. -

Submitted on the old forum by woodenskye

I would go without a fence that runs the whole length of the miter saw station. From the original fence on the saw, I would probably go no more than 12" with the fence. The board is only needs to register against the fence on the saw. I would rather have the work space. With that being said, having a small shop, I'm a bigger fan of losing the miter saw all together.

-

Submitted on the old forum by Kev

For those of you that follow the Woodwhisperer, I'm interested in your thoughts on him doing away with the extended fences.

As posted in another thread, We're just putting the final touches on my next miter station and I'm not too sure that I agree that leaving off the extended fences.

I don't have any inside information other than what's been posted publicly but, I believe the premise is that it's easier to put rough stock up there to cut to rough length with just the standard MS fences.

I'm not sure about all of you but, isn't conventional wisdom to break down rough stock with a jig saw rather than the miter saw? Does that lack of extended fences replace this conventional wisdom? Are we taking shortcuts on shop safety? Am I missing something entirely?

As my plans will be out before Marc's videos come out, I'm very interested to see if there's something that I'm missing? My set up will have extended fences regardless. However, as usual, my fences will be both adjustable and removable. -

Submitted on the old forum by Kev

Well, I paid close attention to the insulation in the new building as well as going with LED lighting. So, I'm hoping that the mini split will keep up in the summer. If if won't in the winter then, I'm fine dropping another pellet stove in.

-

Submitted on the old forum by keggers

I had an air source heat pump installed in my shop this summer. My central unit went out and had to be replaced. The new unit doesn't cool the shop as well as I'd like since every machine in the shop including the lights produces heat. The best it can do is keep the shop around 75 degrees when I have all the machines running. I'm not complaining - kudos to those folks who work with no ac/heat.

-

Submitted on the old forum by Kev

I will be going with the mini split option in the new shop. I’m also still learning open the possibility that I’ll also add a pellet stove for some of those colder winter days

-

Submitted on the old forum by woodenskye

The unmitigated gall of those neighbors coming over to drink your beer!

-

Submitted on the old forum by Coop

After a couple of years of watching me working in the shop in the the Houston summer climate, my wife almost insisted that I install an A/C unit. Our winters are relatively mild but there are below freezing days. I looked into different options and for me, the simplest and most economical was a window unit that provides both. It has been a year round, climate controlled shop. With the garage doors closed, it also stopped neighbors from walking over and killing my time and drinking my beer!

Marc's cabinet builds

in Shop Tips and Techniques

Posted

Follow up posts -

1) Definitely a good and money saving idea in the shop. It can be a pretty common technique, bath room vanities come to mind. If you mass produce vanities in this way they will work in pretty much any bathroom's plumbing layout. When we bought this house the base cabinets in the kitchen were built like this also... made cheap cabinets even cheaper.

2) Time and money saver for sure but, not always the best idea. It's really dependent on the wall behind the cabinet or holes/openings that you have in the tops.

I'll be building a new miter station for the new shop and all the cabinets will be modular, similar to what Marc did. Even tho I should have perfect walls, I may still put backs in the cabinets just to keep dust and crap from getting in the cabinet. We'll see when I get there.

3) So money and time aside ... would the biggest thing be dust and crap getting in there through the back? I guess especially on a liter saw station where dust will be plenty...

My walls are ok. Mostly straight but not flat and typical quick construction built. However I’ll be redoing the drywall and I hope to get them flat and not warped. Also nothing crazy like he has at the bottom.

4) For me, yes. I put things in drawers and cabinets to keep the dust off. Another thought to consider... You know that little tiny, very important, item you store in that cabinet? You know it's going to fall out the back and under the cabinet forcing you to either tear up your cabinet or buy another very important little tiny item.. Murphy says that will happen.. Just saying...

5) Hah. Ya you are probably right on losing that important tiny little part. We could still take cabinets out though. As much of a pain as that is

6)Would that be a legitimate consideration being a miter station? A lot of work to get that set up again.

If I were doing open backs, I would leave the bottoms removable for exactly that reason.