Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

2,097 -

Joined

-

Last visited

-

Days Won

62

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Posts posted by Woodenskye (Bryan)

-

-

I like the inlay with the border. You could use your new laser and make up a bunch of your logo and in lay that into projects, or the initials of the person your giving to as a gift.

-

That’s an incredible difference and really pops!

-

1

1

-

-

Only thing you forgot was the manual for the DT jig, since it seems you always need to read again to use! 😂

-

3

3

-

-

Seems to be working fine on both an iPhone and iPad

-

1

1

-

-

9 hours ago, Chet said:

The finish is General Finishes High Performance. It was close, I had just a little left in the can, about a 1/4" in the bottom. I was letting my supply run down because I want to give Target Coatings WB Conversion Varnish a try.

Kathy is having some on going challenges after the hip surgery on her other hip. At this point she doesn't have any feeling in her foot which is make the physical therapy a slow process. We saw her surgeon last week and after conferring with the neurologist they believe she has a pinched nerve somewhere between her lower back and lower leg. We are going for an MRI next Wednesday.

I hope she gets the relief, I know what she is going through. I was having numbness and pain in my feet and when finally got imaging done, revealed a slight spine curvature and 3 back fractures. I’m not doing surgery, but did get injections and I got an infection in my leg and made everything worse, basically couldn’t walk for a month.

-

Great work as usual Chet! Hope all the medical stuff is behind you!

-

I think the only option is to make a funnel like system which directs dust to the port itself. I still don’t think this would capture everything, cause a rapidly spinning blade and light material cou,d still escape any type of funnel or chute you could design.

-

Looks good! How high is it from the hearth? Picture makes it look low.

-

I’m a little surprised you’re waiting for edge banding, thought you would have enough walnut to cover those edges!

-

2

2

-

-

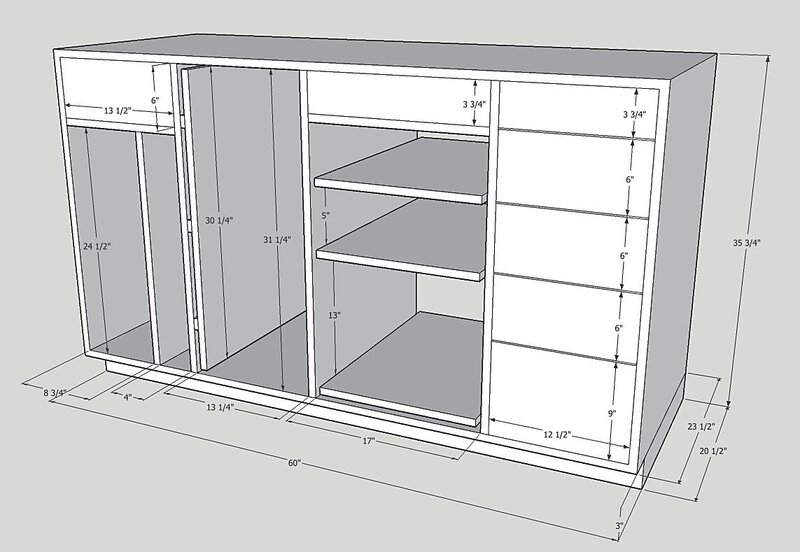

58 minutes ago, Kev said:

Spent some time today refining the plans to ensure all the numbers were correct. This drawing accounts for glides, material thickness, and the base. It also makes it just a little taller to be just about even with the router table and adds a drawer at the top of the systainer storage.. I left ~1/4" on the top for either laminate or hardboard

Now with some real numbers, I'll cut all the pieces to size today and then I'll be on hold until the edge banding arrives. All of the exposed ply will get walnut edge banding.

After the edge banding is complete, I'll cut all the rabbets and dados and start the assembly.

So you will have this wrapped up by Friday Mr. Gonzalez!

-

1

1

-

-

4 minutes ago, Kev said:

Gave this some thought as well.

The BS and RT are different heights. I chose to make the cabinet lower than both but, would be easy enough to have a support jig to set on the top at the appropriate height for each. Plus, there's a storage place for it with the circle jig cubby..

How much difference? If you don’t mind a support jig, then I would make even with the lowest height, then you only need 1 jig. Now if the difference isn’t much a jig might not be needed. Example if you built to RT height and bandsaw was only an inch higher, a jig may not even be needed. Now if it is the reverse, I would want the support for RT because if the piece were to tip it could create a bigger safety issue or an accuracy issue if the piece tipped while routing.

-

I wouldn’t be concerned about the outfeed, cause the cabinet could serve as extra support for longer pieces, provided BS and RT are the same height. If they aren’t I would rather have the BS outfeed support.

-

Good job so far!

-

1

1

-

-

They may be pricey, but from what I have heard, there is nothing like them. I know a guy that uses them in his shop. He always said it’s like how most people think Festool is so expensive then you use and it’s no comparison just on a bigger more expensive tool scale.

-

1

1

-

-

If you can I would get 55 and 106” tracks. I don’t have the room for the long track and that is the only thing I don’t like about my track saw.

-

1

1

-

-

3 hours ago, Coop said:

That’s sweet! What is going in the left compartment?

Stuff for the table saw! Sorry Coop, couldn’t resist.

-

2

2

-

-

Really fantastic! Looking forward to the cushions being finished!

-

1

1

-

-

3 hours ago, Kev said:

I've built a few. Wish I was at home, I'd just share the plans with you..

From memory, I thickness'd the lumber to about 3/8".

I usually use ARS on these and never had an issue.

I've used both acrylic and glass. Both work fine. If you go the acrylic route, just choose something a little thicker. Also, not sure if you've priced this stuff lately but, it's gotten crazy with pricing!

Thanks for the reply! Yeah I have priced out stuff from amazon so I have a rough idea of whether build vs buy makes sense. I have enough quality lumber, just not the ply for the back and acrylic, so it will heavily factor into the decision.

-

Has anyone here built a display case for a burial flag for a veteran? I have some questions before I think about making 1 versus buying.

1) what is the thickness of the wood sides? Overall dimensions?

2) what finish did you use, has it had any affect on the flag after time has passed?

3) did you use real glass or acrylic?

-

2 hours ago, Chet said:

I was just looking at fireproof cabinets on Uline. I did a quick measurement of the space my stuff takes. They have on that is 17' X 17" X 22" for $635 or $725 with the self closing door.😮

I wonder if someone will pay me $90 for closing a door!

-

2

2

-

-

So just watched the video, which was your usually quality, but I don’t see how this is a game changer compared to a normal feather board. I agree there should be a way to secure to table and not just rely on the user to set up properly. I don’t know the cost, but to me personally it would be a hard pass no matter the cost. Why is it called compass anyways?

-

Thanks for posting the pictures. Kev and I generally don’t agree on miter saws, but he is right in this case, the saw isn’t a space hog when looking at the storage component. A shop reorganization would be the first place to start. My shop being a 1 car garage, I can’t keep stuff that isn’t used all the time. My miter saw when in the shop Is on a stand with wheels and is jammed in with all the other tools I need to move out to use

One of the drawbacks I see to your shop is the location of the doors to the house and backyard I presume. They make that part of the shop somewhat unusable, or a place to keep things. Since you aren't parking in there maybe you could disable access, not by removing or building a wall, just placing a tool in front. CNC may be best option.

-

1

1

-

-

I don’t think your crazy, I just don’t remember your shop layout so it may not give you the space you want or make it more efficient.

-

1

1

-

-

Geez at this rate he may have to take it home with him.

-

1

1

-

Tool Manual Storage

in Shop Tips and Techniques

Posted

Basically keep in a Rubbermaid in my office/Attic. They don’t need to be in my shop in my opinion. I can walk inside or pull up on the phone if needed.