Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,430 -

Joined

-

Last visited

-

Days Won

26

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Posts posted by Tmize

-

-

The 6/4 top mill out at about 1”? I like the thumb nail profile. Did you just bury a round over bit to make it or do you have a special router bit? It coming together good looks great.

I see some curly maple in the drawer sides?.

-

My Main question as this is a pretty simple build for the most part ... the apron/wrapping of the wood corners (not sure what to call that) ... Will that cause issues with wood movement? Or would it not be too bad?

I was just reading a project build of one Garrett Hack huntboard. The bottom of the case is a floating spline along the depth for wood movement. I got to thinking about the table top you posted. In this case it could be built like frame an panel door. You could just leave a small reveal around the border.

-

3

3

-

-

Yep I’ve cut tapers wrong before. I think I’ve cut just about every joint wrong at least once?

-

1

1

-

-

I think you nailed there Bryan

-

1

1

-

-

I’ve had a lot of those days lately. Wish you luck

-

1

1

-

-

It’s your piece don’t let me change your mind. I’m just some random guy on the internet?

-

23 minutes ago, Kev said:

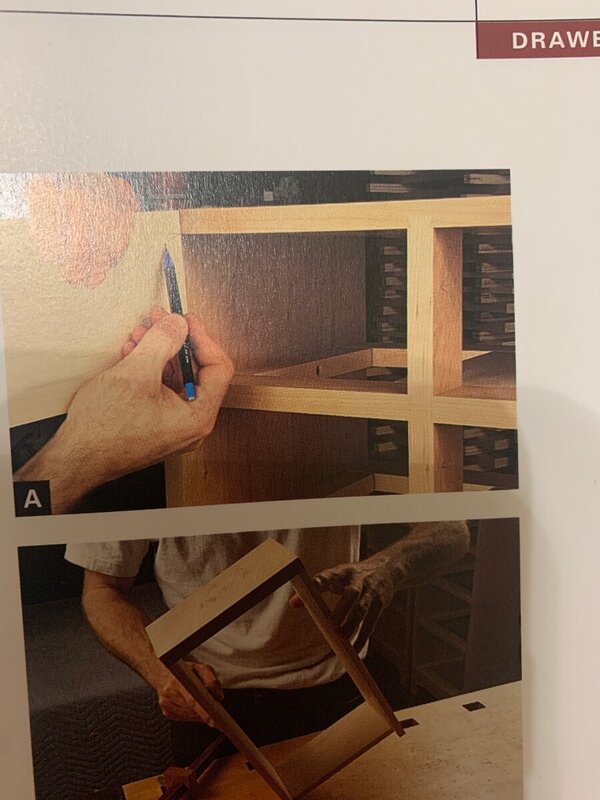

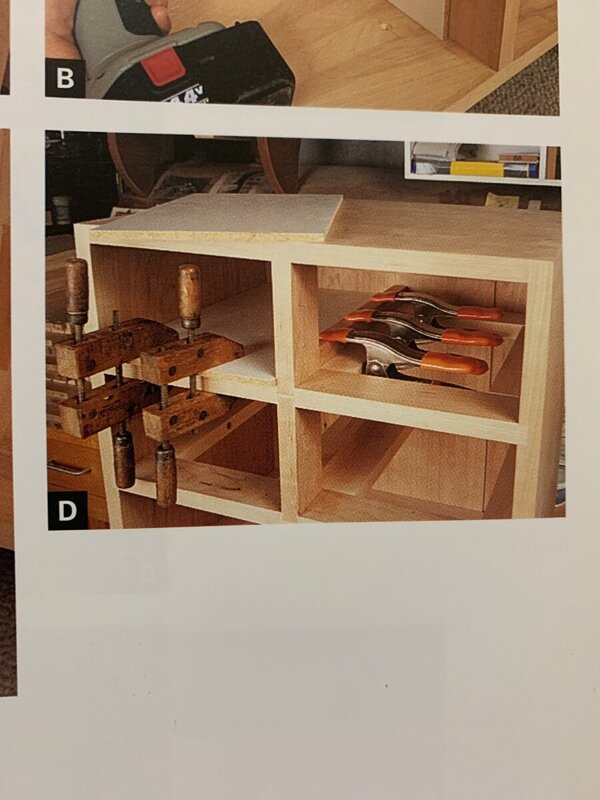

The vertical dividers are full depth of the case. Because I cut it 1/4" too narrow, I could no longer use those pieces.

When I was making the web frames several days ago, the horizontal pieces, I made an extra one just in case - These have the African Mahogany on the edge. This piece is about 4" wide. So, the look of the case would be right but, instead of the vertical divider being full depth, it would only be about 4" deep.

If that's still confusing, let me know and I'll stag a picture for reference..

No that’s good I was following you correctly. If your drawer slides don’t need them to be full width I would just do 4” wide. That is actually fairly common on case work when not using drawer slide hardware just the pocket to guide the drawer.

-

1

1

-

-

14 minutes ago, Kev said:

The final straw was cutting the next verticals 1/4" too narrow and I'm out of 3/4" ply. I milled up new edging and contemplated using my extra web frame to just do the front 4" of that set.. So, I'll sleep on that tonight and take a fresh look tomorrow. Structurally, it would be fine. It's just not what I had in the plan and I'll be looking at this without drawers for a while..lol

Ok you lost me a lil bit here. Instead of a full width divider you would just do the front 4”?

-

Great job on the glue up. Got to love when all the planning an layout works out to trouble free an square glue up.

-

1

1

-

-

With the curved top rail that should make the drawer fronts fun to match.

12 hours ago, Kev said:The web frames will be glued into the notches.

If you look at the second picture, you'll see one of the grooves cut in the web frame. All the verticals will sit into dados cut in the web frames and glued into place. I may also add some screws but, they're not really needed. I'm struggling a little to figure out the top center ones as that rail is curved. Pretty sure this will be a hand saw and chisel show after the assembly.

-

I bought the water stone mainly because I didn’t like the way my diamond stone kept getting slower cutting do to it getting finer. I have just a norton two sided water stone 4K an 8k. I know I’ll wear it out sooner or later due to how much I sharpen I like the way it cuts tho. Just looking for recommendations

-

Do they seem to cut as fast? The soaking doesn’t bother me I bought a large Tupperware pan I keep them in an just take them out an go.

-

Some how I missed this the first time. I just started down the water stone road. What ceramic stones did you switch to an why from water stones?

-

I can’t wait to see it glued up. Doing a great job Kev

-

1

1

-

-

Could you not glue up the end panels first? That would take some stress out of it.

-

Hi

in New Members

Welcome to the forum

-

1

1

-

-

Welcome

-

Not much happened over the weekend with this project. I got the frame all glued up an the shelves roughed out an glued an the panels got two coats of paint. Only issue I had was one side of two of the sliding dovetails the shoulder didn’t pull up tight like the others. So since this joint will never see the light of day again. I glue them to tails up with epoxy in hopes it will gap fill the error. I clamped them tight you can see in the pictures.

-

3

3

-

-

27 minutes ago, Jamie said:

Good idea! Could half lap them to be able to break down for easier storage as well

That was what I was thinking originally. Now Chet has me thinking of using plywood to save storage space.

-

I may just go with the kreg save some money. They make good product from what I have used. I just don’t see me doing enough plywood an cabinets to make it worth the extra $$. Now I need to come up with a better method to break down whole sheets. Thinking about building a 2x4 grid to sit on my saw horses

-

Nearly all my ts blades are diablo I think they are about the best value. Now my 24t rip blade is starting to dull an burn I may have to replace it soon. Now I’ve cut a lot with it in the last year an half. For 30 bucks I can live with that consumable cost.

-

Welcome to the forum

-

Hcm

in Power Tools

Think I’m starting to see a trend on here?

-

2

2

-

-

So I’ve got a bunch of plywood cabinets coming up soon so I got to looking into track saw. I know I want battery powered I hate cords an I’m a electrician ?. While searching the web I found Home Depot had Milwaukee 18v circular saw half price with battery $179 so I jumped on that. Then I got to thinking about kreg accu cut xl. It has a bed to attach a saw to an cut up to 106” track. Would it be mistake to go with this or would a true track saw setup be so much better. I don’t do a lot of plywood regularly either way would be better than fighting a whole sheet thru the table saw

A Coffee Table / Sofa Table Set

in Member Project Journals

Posted

That is going to be one hell of a glue up. I don’t envy you at all. ?