Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

6,324 -

Joined

-

Last visited

-

Days Won

583

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Everything posted by Kev

-

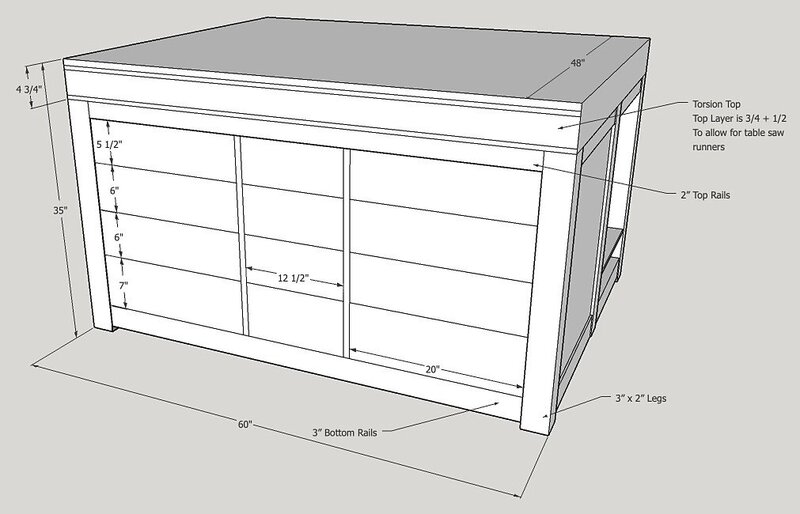

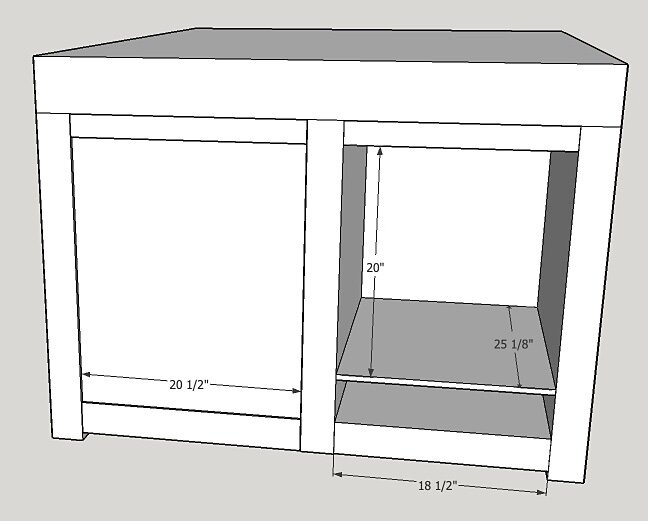

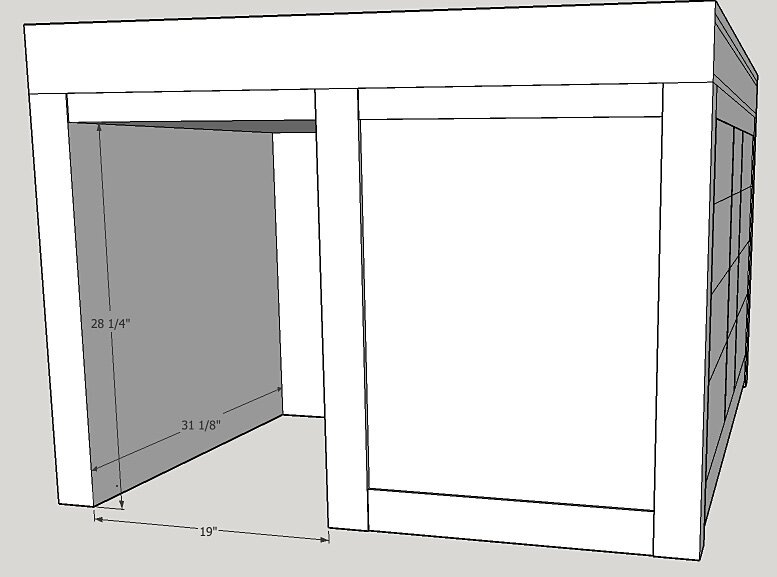

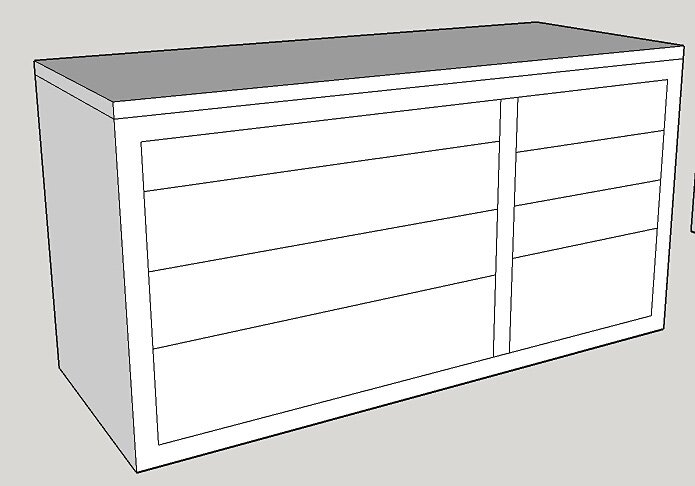

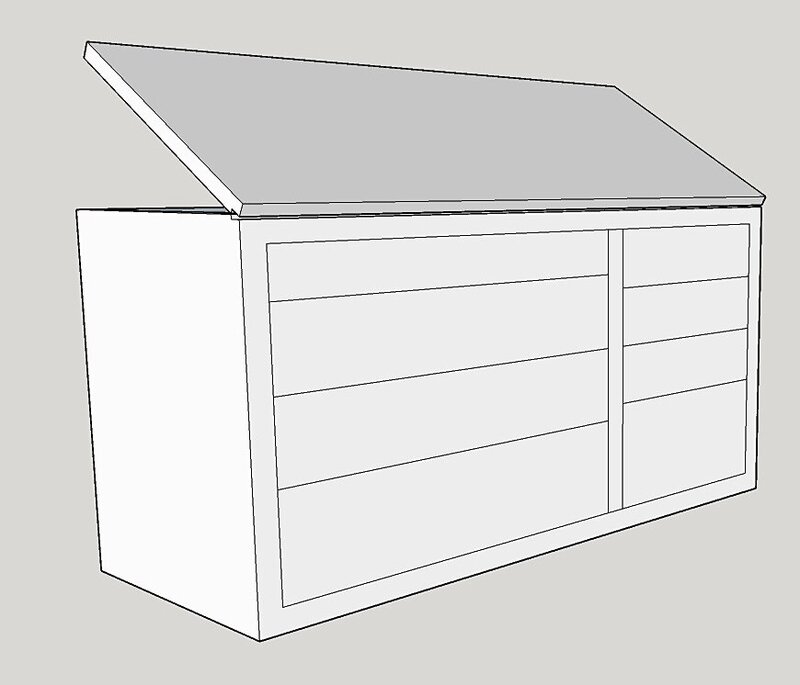

Apologies up front for a long post but, I wanted to put out what we currently have for this OF table and get the ball rolling with some good conversations. Ultimately, the decisions belong to @Olie as it's his table. I can/will certainly make some changes but, I'm still having the issue with Sketchup so, just can't add any dimension changes to the drawing. The drawings will still be to scale, just can't read the dimensions until I get home. Front View: There's already been some changes to this and I just haven't gotten the drawing updated. Jeff changed his mind on some work holding. The top as drawn is a torsion box top which really isn't too conducive to work holding options. So, we're looking now at a solid split top that can accommodate some vise and holdfast options. Some previously discussed details: Solid maple split top African Mahogany base and drawer fronts - Matches his bench - Secondary species for inner structure. Possibly a Benchcrafted leg vise - This could affect the drawer configuration which are not set in stone. Possibly a Veritas tail vise Leveling feet Custom made drawer hardware - We'll have @Dick in the shop to show off his lathe skills for this! Right Side: Jeff is considering his options here so, this could certainly change. Currently set up for a lift and a sander. Pull out drawer below for storage Left Side: Currently designed for a dust extractor but, not set in stone. His shop layout plans has his jointer on this side which adds some limitations to the access on this side. Note: This back corner is actually just a leg and an upper/lower rail - I missed that in the drawing. The rear panel is not solid. Closing: I know this looks a lot like mine. As you know, Jeff had the opportunity to work in my shop (Forever Bench) which I'm sure influenced his "wants". However, this is his table and project so the choices are his. I'm really looking forward to you guys tossing him some different options and ideas. Although it works great in my shop, there's probably some options he's not considering and I didn't think of. Project Dates: November 18th, 19th, and 20th. We won't finish it in 3 days but, can get a good start. Would love to see everyone there!

-

It's hard to say.. I've got some time off this weekend so, I'll get the drawings put up here and we can "group talk" through them and discuss some details.. Once the plans are complete, we'll try and come up with goals and see what the timeline comes out to be. I'm pretty sure it can't be done in a weekend but, should be fun for the group that can attend. That's one of the reasons the planning is so far out.. Was hoping to get more people with more time to plan.

-

Thanks! I think I need to change mine up.. I don't use it because I just don't find it to be very stable..

-

First off, apologies for the slow response to this. My company was having an issue pinpointing some dates on a job that I need to be at. I've got those dates now and have the approved vacation time to ensure that we don't have any more snags! Dates had to move just a little to the following weekend. 18th, 19th, and 20th. I know that's the weekend before Thanksgiving and completely understand if you can't make it. Between the job and my own family stuff, that was the only weekend that worked for me. Another option would be to move it to December which we can do if that's what the ones coming want.. Please let me know if you plan on coming..

-

Very nice work! Interested in how you like the Hi-Vise? I attached mine to the bench differently and am not happy with it. I do have the option to mount it the was you did.

-

We had some brutal weather and power outages so, apologies to anyone trying to get on and couldn't..

-

Agreed.. That's why I added as much as I did to this cabinet..

-

Thanks @Bob! Ultimately, it's that "space to the right" of your machine that I'm after for this top portion. It looks to me like you just put tools in use there which is what I want. Great setup!

-

Sounds like about where I'm at.. I like to make "shop drawings" to keep me on track in the shop. Plans are produced by a friend of mine in CAD which is what I put out on my site. I really like Fusion 360! Just not sure I want to start over as there is a steep learning curve. Since I don't charge for the plans, I would still meet the criteria for the free version of Fusion 460. I found the issue when designing this lathe cabinet. Unfortunately, I had already done all the work when I discovered the issue. Next up will be to transfer the file to my older computer and see if can add the needed dimensions from there.

-

This will be dedicated to the lathe but, I also need it out of the way when not in use.. It is possible that the pull out tray might come in handy when milling lumber for a project considering it's proximity to the planer.. That would purely be an added bonus though..

-

Yes.. The tool storage is only meant to be used when using the lathe. The rest of the time, those tools will live in the drawers... I've only got 28 total inches of height under the lathe so, even with wheels, this is just not a very tall cabinet. By tilting the top up when using the lathe, it makes those tools much more accessible. As well, the top "drawer" is actually a pull out tray which will act as another horizontal surface to set things on. So, turning tools on the tilt top in some sort of holders not yet designed and all the other odds and ends on the pull out tray. I have a DC drop over there already specifically put there for the lathe. I purposely designed this cabinet at 18" deep to allow for a stand and hood behind the lathe that can stay there when the cabinet is put away under the lathe as well as be easily movable when the lathe is in use. I hope I'm explaining what's in my head well enough to be understood? I've not seen a design like this anywhere but, I also don't watch a great deal of turning videos..

-

There will be "tool holders" on it. It will be pulled out and directly to the right of the lathe to put these tools on when working at the lathe. When we were doing some turnings on Sunday, I ended up pulling the shop cart over there to set things on and just figured I could do a little better than that.

-

Even though I'm having some issues with Sketchup, I wanted to draw this one out while it was fresh in my head so we could have some conversations and maybe some better ideas. Dimensions aren't shown but, this is to scale. One of the things that I noticed during our turnings the other day is that my lathe corner didn't work as well as I had hoped. The major deficiency was a place to set tools when switching from tool to tool. This cabinet will live under the lathe and be pulled out when turning. It would become an additional work surface and place to store the tools being used on that project. It will be on 4" lockable casters. It's 45" long, 18" deep, and about 28" tall with the wheels. My thought was to have the top able to tilt up at a fairly steep angle when the cabinet is in use. Obviously, I would need to add some tool holding to the top which would definitely make the cabinet a little shorter. And then, when I want to put it away, the top simply lies flat on the cabinet and stores under the lathe. Additionally, the top wide "drawer" would actually be a pull out tray to store other things while working at the lathe. Of course, the additional drawer space will be great for additional storage for lathe related things. Thoughts?

-

Completely understand and I know my version of Sketchup is way out of date. My issue is $300.00 a year to get me one option in the software that I need. That's a tough pill to swallow! And, of course, if I download the new free version, my old version will be lost on this machine. Now, I do still have my old Mac so, worst case, I might have to go back to that one for doing designs..

-

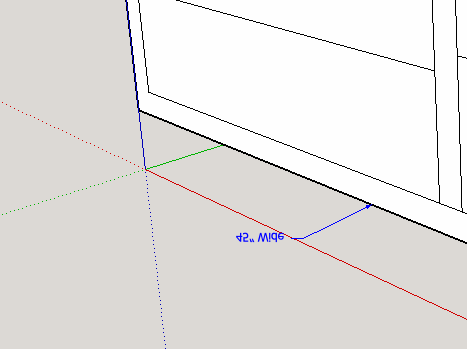

I'm hoping someone here is way better with Sketchup than I am! For starters, I'm running a very (and I mean very) old version of Sketchup that is not on the cloud. It's always worked well for me but, a recent update of my operating system is causing an error that I can't seem to fix. Whenever I add dimensions, it's flipping them upside down making it very difficult to read. I've tried everything I know how to do to flip the text over without luck. So, it would seem the obvious is just update the program right? Maybe.. If I want to run the free version, one of the drawbacks is "limited export options". I need to do some research to see exactly what those limitations are but it looks like the usual 2D option I use to export is only available in the pro version. The pro version is $300 a year on a subscription which really isn't acceptable for what little I do. Hoping some of you "smarter than I people" can offer some insight??

-

Got the mess cleaned up today and the lights installed.. Doing the few turnings we did made me realize I need some additional tool storage! Will probably create a new thread for that.. May work on some designs while gone for work..

-

Had a great day in the shop with Richard P.! Can't thank him enough for coming up to the shop today to break in the new lathe! We definitely made a mess but, it was well worth it! We turned quite a few small things and got to test drive this lathe pretty good. Got to use my new Nova 2" chuck as well as test drive the drill chuck that I've had for quite a while. Everything worked flawlessly! We even got to test drive some of the Ashley Harwood turning tools that were an absolute pleasure to use! These are a couple of the items that stayed behind with me but, he also took a couple items home that I didn't get pictures of before he left.. A cheese slicer and a pepper mill. His pepper mills are awesome! These 2 items above were turned from some left over scrap from the bed build. I had lots of 8/4 cherry on hand so, was some good practice stuff. Richard brought a couple of glued up blanks and those were the items that went home with him. I'm trying to talk him into joining this group to add to our (nearly nonexistent) turning group. If he does, I'm sure he'll add those pieces to this thread. Richard showed up with a whole bucket full of cool stuff for the lathe! From his own turning tools to several chucks to use on my lathe. I learned a lot! For starters, I learned that there's still quite a few tools I need to add to the arsenal but, I've got a good start! Secondly, I learned that I have a lot more to learn! Was an absolute pleasure to bring a pro into the shop and see a master at work! Now as a rookie should, I'll head out and clean up the mess. Small price to pay for an awesome lesson!

-

Those are just AA

-

I've been running THESE for a while now. I used them for the audio gear for recording and have had great luck with them.. I also bought the charger.. Not overly cheap up front but, they have paid for themselves a few times over..

-

Yes, the head stock can be reversed or run off the other end. There's also a 20" extension bed that can be bolted onto either end as well which would really extend the machine if needed.

-

Well, it's finally in the shop! Big thanks to @Ray Martin for the help! That thing is heavy! Haven't turned anything on it yet. Only fired it up to make sure it works. Sunday will be dedicated to making a mess and turn some stuff day.

-

Yea, there's a few options we can look into if needed. The important part is to make sure there's plenty of air flow around it.

-

Yes, we do.. The biggest concern was the accumulation on the top.. We've talked about adding some removable lattice to the sides and front to help with that issue if needed. I think we'll watch it a bit closer this winter and see how it does..

-

Got a good early start today to beat the heat! Got all the drip edges, roofing, and flashing installed! Should be good to go for the winter! Not fine furniture standards by any means! Just some minor landscaping now!

-

No.. Probably a Fir of some sort.. That's what you find here in the Northwest.. Just pressure treated for ground/weather contact.