Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

6,324 -

Joined

-

Last visited

-

Days Won

583

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Everything posted by Kev

-

I know she wants a bunch of other things but, there's a lot between wanting and actually ordering it.. As for her friends, who knows..

-

I haven't tried this little trick.. I use the domino a lot to create those small reveals.. I start with the most shallow one first and then deepen the domino to get the other.. I can see where this might come in handy from time to time though!

-

I don't think the African Mahogany has really too much to worry about with food contact.. It's essentially just a softer Sapele. I'll probably do a maple board with some African Mahogany strips for the cutting board. The Lazy Susan will probably be African Mahogany, maple, and Bubinga with a couple Wenge stripes.. Unless I totally decide to do something different when I get to the shop that day... 🤣

-

Things got a little more interesting when I closed up the shop tonight.. I sent this picture to the client after I pulled the legs out of clamps so she could see the progress.. She responded very quickly! Excited about the progress, she requested to add a cutting board and table lazy Susan to her order... Nothing like stacking up the work I suppose... 😂 Now I just have to figure out how to try and match the cutting board to the table since African Mahogany is probably a little soft for a cutting board..

-

Mortises were cut with the router and dual edge guide..

-

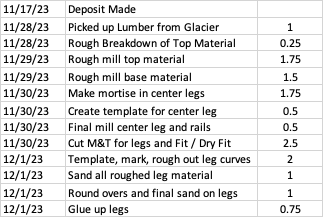

Another good day in the shop but, a shorter day. Had some errands and stuff to do today and we're having dinner guests. I got all the curves and and things cut in the leg pieces and put together for a dry fit to ensure everything would go together correctly. I did create a template to use to maintain symmetry from piece to piece. After what seemed like an eternity with the sander, I got all the round overs completed and then got to do some more sanding making sure all the rounds overs were correct. From there, I finally got the legs glued up and into clamps! I think I'm going to help @Ray Martin tomorrow so, probably not much progress on this but, I'm pretty happy with how smoothly things are going.. On that note, here's the progress report on the time.. Currently at 14.5 hours. I'm probably a little ahead at this point on time because everything has gone so well. Still a lot of work to do and 27 hours to get it done to stay on target with the quote.

-

Pictures make it look like it's ready for paint! Looking forward to seeing it in person tomorrow!

-

Well, we just got the confirmation that this will finally be tied into the house next Friday (8th).. Looking forward to it! They're won't be any interruption for the forums.

-

She'll be able to unscrew the top but, that's as far as the breakdown would go..

-

It won't.. Although it looks like it will, because of the top rails for additional support this table will not break down.

-

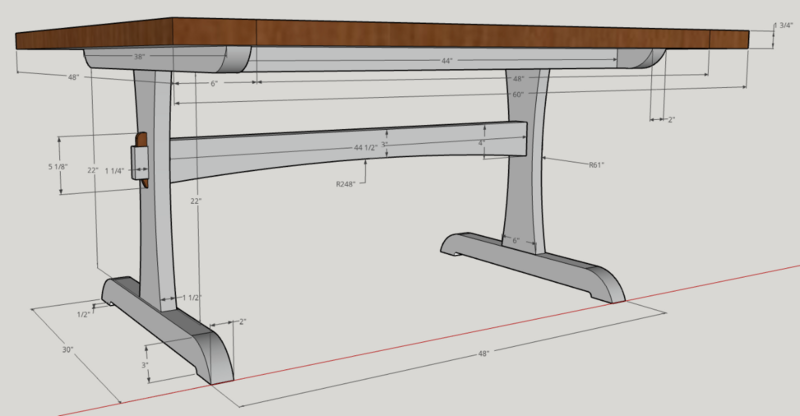

I really only create drawings for shop use.. I don't usually include joinery because there's just too many ways it can be done. Many times, I don't know exactly what I'm going to do until I get there. Today is a prime example.. I could have easily broke out the domino for the legs on the trestle table but, I wanted to do it a little more traditional. Plus, I think the traditional M&T was a stronger option for that particular joint. I reserve the right to break out the domino on the upper rails though since that will simply be the faster option with no real down side.

-

I'm not doing the painting, the client is. However, I did supply several raw blocks of poplar today so that the client can create her own samples to decide what she likes. With that said, I did show her some painted pieces I've done that she was very happy with the look of. So, she's going down the General Finishes Milk Paint road and then I'll shoot the base afterwards with General Finishes High Performance. I'm looking forward to seeing her color choices for the base!

-

Yes, originally I thought the finish was going to be Rubio so that's what I quoted. However, the client wants the feel of Rubio but, the look of Potassium Dichromate. So, I'll be doing both finishes on the table top. I already had the Potassium Dichromate on hand as a tiny bit makes a lifetime's need of it so, didn't charge any extra for material. The cost will come with the labor.

-

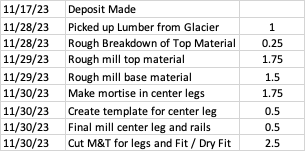

Another really good day in the shop! I final milled all of the leg pieces, got the mortises for the center stretcher done, and got the M&T joints done to be able to put the legs together. I also created a template to mark out for the curves in the side pieces and got them marked. Still a lot of work to do before gluing these up but I'm happy with the production for the day! So, where's the cost at? Currently sitting at 9.75 hours A little over 31 hours left to finish this project. Maybe the finish won't bite me as bad as I thought!

-

Nice! I do use a lot of spiral notebooks that have graph paper in them to sketch out some rough drawings.. I usually transfer them to sketchup but, not always.

-

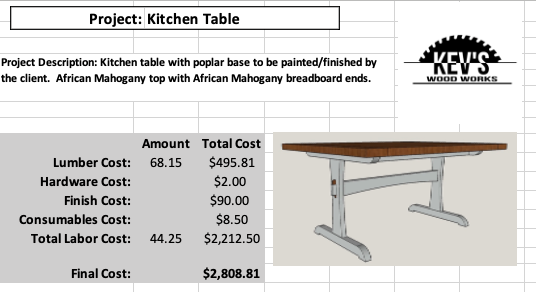

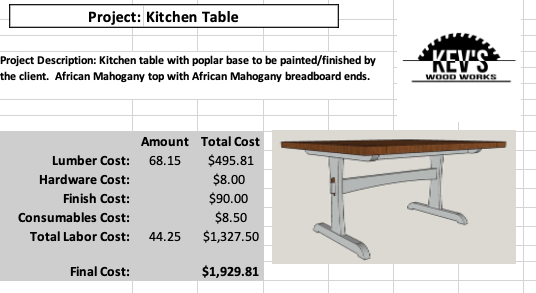

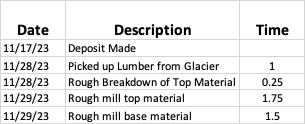

Ok.. Regardless of coming in under or over my bid, I'll try and take this step by step and explain myself along the way. Any question is fair and I'm happy to answer them.. For starters, the client is in a bit of a rough spot in life and also a distant neighbor. So, I lowered my hourly rate to try and help her out as well as generate some future business as she wants a lot more than just this table for her kitchen/dining area.. This is what my normal bid on this table would have been.. Because of what's mentioned above, I lowered my shop rate and here is the quote submitted to the client. I lowered my labor cost to $30.00 per hour. Since this is the actual quote given to the client, these are the numbers I'm trying to hit. If I missed anything, that's on me. If I totally underestimated something, that's on me. Barring change orders, this is the max that the client will be charged. I may have missed a bit on the finish but, we'll talk about that in a week or so when I get there. The client wanted a little different finish that I probably could have charged more for but, didn't. I'll go into detail when we get there. Lumber: To catch things up to where the project actually is.. I was able to cut a "cash" price with my local HW dealer so, lumber came in a little less than expected. Bid: $495..81 Actual: $416.25 Difference: $79.56 Assuming I don't need any additional lumber, this amount will come off of the final bill to the client.. Note: I do need an additional board of poplar for the center stretcher on the base because of my error. I just have to eat this, it was my error. This kind of stuff is captured on my quote sheet for the client to see in the end. Labor: Labor will be an ongoing increasing number as the project progresses but, I will try and update to real time numbers at the end of each day.. We're only in one day and only 4.5 hours of that was actually billable. This includes a reasonable time to pick up material at the HW dealer. I keep track on the white board in my shop and don't claim time that's not actually spent working on the project. This is transferred to my quote sheet so that everything is in one location and completely viewable to the client. I also keep track of deposits or changes here as well.. Here's what the list looks like so far. Total: 4.5hrs I didn't charge for consulting time today figuring out the board configuration for the top. She really didn't make any changes to what I had come up with so, was just conversing with the client time in the shop discussing the project. Bogs down the progress but, keeps the client happy. So, what's all that boil down to? There's $1192.50 left on the budget and a $79.56 refund due on lumber since I got a break. In other words, I need to find a way to complete this project for $1112.94 or about 37 hours of work including finish to stay on my quote. So far, I'm feeling like my quote is pretty accurate to what the final will be.. We'll see Note: This doesn't account for the finishing stuff mentioned above which will probably bite me a little but, shouldn't be too bad.

-

Good day today overall! Got all (all but one piece) the lumber rough milled. Also had a good visit from the client to approve the orientation that I picked out for the boards in the top. African Mahogany is tough since it looks different from all angles! I thought it was important to have her approve the final look of the top especially since it's purely an aesthetic decision. I did cut the center stretcher too short and had to reorder one piece of Poplar for that. My mistake at no charge to the client. Will pick that up tomorrow or Friday. Here it is, all stickered and stacked up! Hoping for little to no movement since it took a bit to get the African Mahogany flat! Will probably go back to the top tomorrow and see about getting it glued up! Hard to believe there's a dining table sitting in that pile!

-

Far from a "young whipper snapper" but, too old to keep up with the technology I guess..

-

Still sorting through my Sketchup issues but, I did sign up for their cheapest version so that I could add dimensions to this table and make a workable shop plan. Ready to get going on this one! If anyone is truly interested in how I bid this project and how I keep track of things as I go, I'll be happy to share that here with you???? I'm more than happy to share real time numbers with you throughout the project. I picked up all the lumber yesterday and am getting ready to head to the shop to do the rough milling for the top. So far, the client has a refund coming on the material since I was able to get it cheaper than the original estimate. I'll hold on to this information until I determine that I have enough material and that it meets standards. Always nice to have a little cushion!

-

Mine isn't much newer 😂

-

Back on this subject.. Sorry... I'm contemplating some major upgrades in 2024 so, may need to actually check out the free version of Sketchup on line and then see if I need to upgrade. Has anyone else tried the online version? Were you able to export to 2D or 3D which is what I need most? Were you able to open older drawings done and then add to them?

-

Unfortunately, I know that traffic jam well! The hotel I usually stay at is about 6 to 7 from the plant. I always have to leave for work one hour early just to ensure that I get there on time..

-

So, here's what I did on the rail and it works well.. Fills in that gap nicely and still leaves room for the DC.. Here's mine which obviously needs to be cleaned! If I wanted/needed more room back there, I would just laminate another piece(s) on until I had enough room to keep the saw in tact and allow enough room..

-

What we missed was the location on the saw.. I'm just not sure yet if this will be an issue on this bench.. I'm sure he'll need a day or 2 to get things in place and assess it see if it's going to be an issue or not.

-

Well, admittedly, we didn't do enough talking/designing around the DC so, may create an issue in the future. We didn't consider his DC out on his saw (which also has an over arm collector) so, may create an issue with the cabinet we installed. On the bright side, there should be enough room in that cabinet to allow him to do what he needs to go.. I'll let @Olie go into how that actually fits up to his saw and what he'll need to do to correct any issues.