Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,605 -

Joined

-

Last visited

-

Days Won

98

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Everything posted by Bushwacked

-

I was sitting in my shop the other day just kinda annoyed at the clutter of trying to get to the drill presss/bandsaw/and planer … the though cross my mind of potentially getting rid of of the mitersaw station and lower cabinets. Keeping the upper cabinets. The lower cabinets take up quite a bit of room, but actually do not store all that much. Mainly has most of my systainers in the 2 right ones, then my HVLP in the middle left and random crap in far left. I would build a rolling stand for the mitersaw and use the indeed/outfeed support stands if needed. Then tuck away when not in use on by the wall. Can put the planer up next to it too. then I could also move the bandsaw over there. Use the wall for some storage too. Where it fits. Then would need to build out storage solutions finally under the CnC which I would finally be able to use the side of it now with the space. Then storage in the outfeed/workbench area. crazy??

-

great work there! In all my video watching ... never did making my own tennons come across my mind! I think that would be a lot easier to do on bigger pieces like ours. I think if I would have thought of this, I would have gone that route instead of what I did. I guess next time!

-

very nice days work there!! Is it so wide, just solely because the vise? Or did he want a monster?

-

Thanks guys! So, yes there is a door on it, however with the kids, the door is almost never fully closed unless they are in there or I shut it at night. So it is normally somewhat open when people are here so that is why I am just putting a little more into it than some basic paint in the coat closet section.

-

Maybe something like this? Not sure on color, but maybe a nice blue help make it more "fun" in there

-

I was watching the big cabinet built in one .. noticed he does the same for the cabinets sitting on the desktop, he routes a grove in there and slides the cabinets in. Seems like a pretty cool alignment/install trick

-

yes, definitely some paint! I was thinking of like a thinner version of what we have without chair rail moulding ... like 1/2 and 1/4 thick pieces to save as much room as possible. As for the bench, I was thinking maybe even tearing that one out and maybe going even lower with it? Right now it is about 13" high, I was thinking maybe 7-8" high as a more low profile bench and giving adults more head room. You pretty much have to bend all the way over or slide on your knees to get out of the room anyways. Yes, the cubby was going to be replaced with something nice. I put that in about 5 years ago maybe? Just to give them a quick book storage spot with scraps I had laying around. I asked my kids ... they wanted something like the below coming out into our master since it shares walls haha ooooh, will check it out. Is it the casing for his office with the massive built ins? I saw that one and was thinking about that type of look just scaled way down.

-

Wanted to pick your brains on this … I am wanting to get some ideas on how y’all would tackle this design wise … Here is how the rest of the house is with the wainscoting… I don’t think a direct match would work in there as chair rail sticks out too much. So maybe some basic wainscoting and a look of separation for different kids areas to store stuff? I would want to try and keep sports bags in here and extras like that. No real need for a true coat closet per say with a bar across the front. now here’s the inside of it. Only thing we have done is put the wood floors down in the first half. It’s got this random shelf … here is the inside … the previous owners just had the builder toss some carpet on the bench and floor. It’s not actually connected to anything or held in place. I mean it’s fine as it’s the tornado shelter for the house that my kids have turned into a little hide and go seek place and a “fort” of sorts

-

-

had a change of design here ... really wasnt happy with the tenons for the BB ends as it was tough keeping everything aligned properly. After thinking about it and measuring and trying to come up with a solution ... I gave up on the BB ends. Chopped them off this morning and ordered 2 x 32" C Channel pieces that I will toss into the bottom instead.

-

What does AM go for per BF up there?

-

oooo thats a great choice there! Cant wait to see the combo together!

-

Coop send me cost, send Kev shipping

-

if Coop is not on standby ready to come in at a moments notice, I dont feel at ease with this

-

this will be a lot of fun to watch! How much video do you think you will be getting from this?

-

You know, when you mentioned this I was thinking I was going to just hate it ... now that I have seen it, its actually not bad looking at all and I might actually work that into some future designs.

-

may be kinda late here as well ... sorry Coop, but I used Minwax ultraflat on that white oak countertop I built ... could hardly tell there was even a finish on it

-

so you made BB's that were a tad thicker than the top? I am not sure I have ever seen that before ... do you have a pic?

-

No the BB ends were milled at the same time so they will be the same thickness, however I do kinda like how he leaves just a touch oversized on the ends to help with expansion and contraction. I attacked it backwards from how he did it for 2 reasons ... I had to order an edge guide, it shipped from EU, however it was half price so I dont mind waiting ... 50 is way better than 100. Then I cant really use the dado to sneak up on a nice fit anyways so just a #4 once I get the mortises cut to sneak up on the fit. With something this big, not sure if it matters how to achieve the snug fit ?? watching this one ...

-

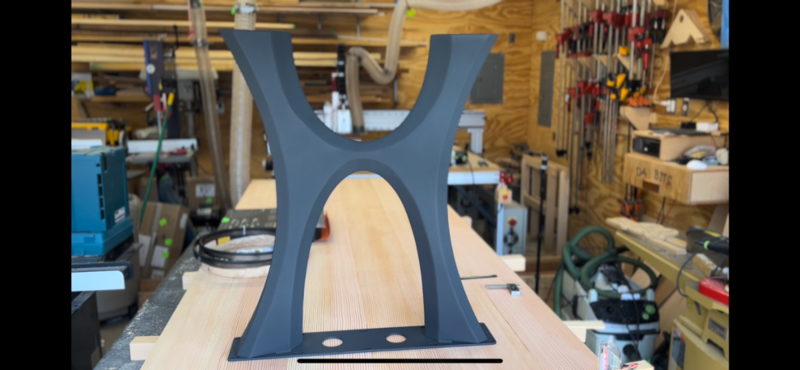

Started on breadboards … this kinda kicked my butt today on how to support the router on the very ends haha. got my massive bit in and ready to go .. marked and ready to cut … now time to go watch Marks video a few more times before I start the mortises. I left the tenons a tad thicker so I can plane down to a nice snug fit … hopefully it works out like I planned haha

-

I came for the same knowledge haha

-

awesome! glad to see you back in the shop.

-

LOL!! it crossed my mind for the emotional stress of not having a bandsaw at the moment 🙂

-

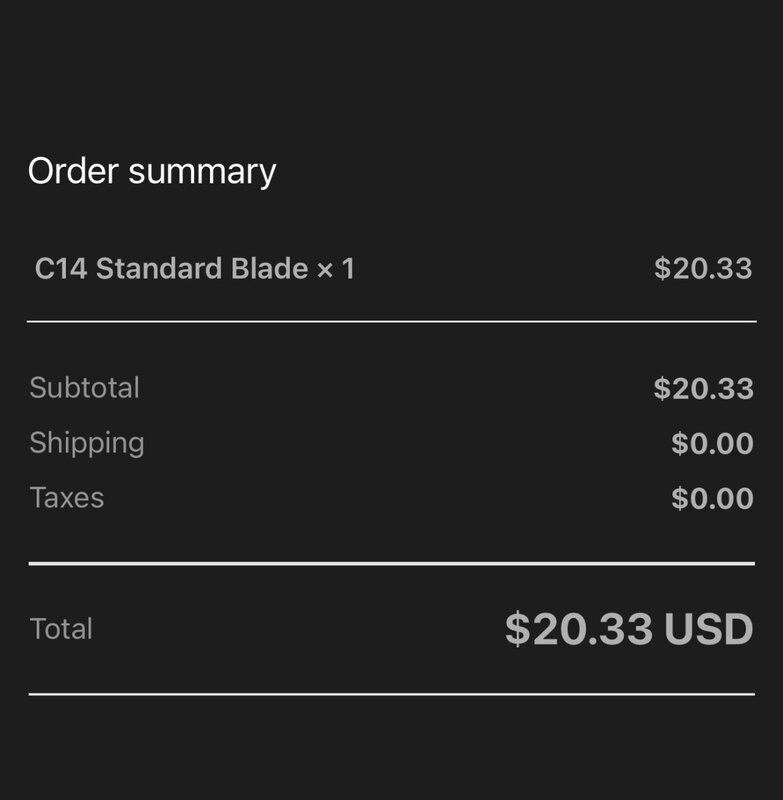

Invoice for the blade … gotta say the Harvey support has been amazing! I’ve had 9 email replies (18 total messages back and forth) since Monday. Super friendly too.