Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

277 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Everything posted by RxR Sawdust Station

-

Ha! It 'may' have been your video where I saw it! ?? I did recently go back through your YouTube library the other day ? ?, RR

-

You 'may' find something like this useful. A drill guide we used in aviation - the UDB bar in the bottom. This specific drill guide was used for repair bushings mostly, when a mechanic mis-drilled a hole or the hole they processed failed inspection. There are varied diameter guides that go in those openings on the ends. You clamp it on one end or other opposite the end your using (we bolted/fastened them down with temporary attachments). I have some here but mine aren't readily available - they're used with drill bushings that fit into those holes and are held in place by those slotted shoulder bolts similar to this. And, again, the inner diameter is whatever drill your using. Then, that same drill busing can be used in what we called a "Egg Cup". They're handheld and use three points of contact to keep you 90° to the surface you're working on. The bushings above are the ones I have and you can see better how they lock in place. You rotate the bushing guide under the head of the bolt/screw and it prevents it from moving around until you turn it in the reverse to free it. I am a little surprised at how many aviation and machining tasks and tools/shop aids can relate directly to woodworking. Regards, RR

-

I know I recently saw a woodworker who added a little easily removable, task specific wooden bump-out support in front of the blade for one sled or another. I thought it was #DavidStanton but I can't find it right now. It was just a little bump-out. It didn't look to be even 12 inches long or wide. It looked like it solved that problem. ?, RR

-

Axiom Stratus Air Cleaner/Air Filtration....

RxR Sawdust Station replied to RxR Sawdust Station's topic in Power Tools

Thinking of our conversation, I saw this the other day - Laguna 540, 730 or 1200 CFM Air Filtration System is on sale (not related to Black Friday/Cyber Monday, I don't believe) down from $389.00 to $299.00. https://lagunatools.com/classic/dust-collectors/air-filtration-unit/ There are several features I really like about it. The Air Filter Indicator for one, its CFM ratings for another. The electrostatic pre-filter is washable. ?, RR -

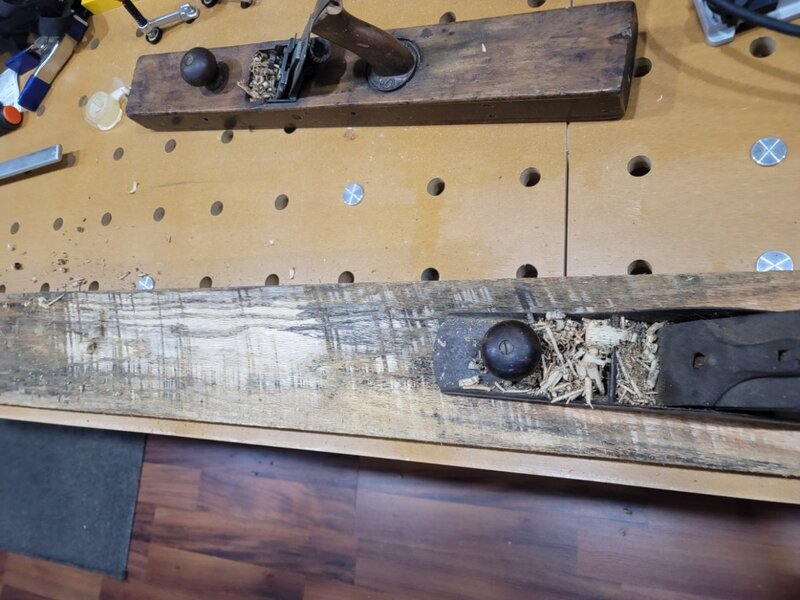

Hello T!, You've been messing around in my brain? ?? I have been pondering that very thing. However, I had not heard of the playing card method. That sounds interesting. The Gage is 24 inches. The #7 is 21-1/2 inches. How does that work with the readily available Float Glass that's typically only 12 inches long? As an alternative to the Float Glass' relative shortcomings ? I have considered a Surface Plate. What do you think of that? Grizzly has a 18" x 24" x 3" Granite Surface Plate (Model #G9654) for $77.95 - flat to within .00015 in either direction. With my machining background - CNC and Manual - it includes being a certified CMM (Coordinate Measuring Machine) technician, I am very familiar with surface plates and, the size seems right to me. But, I don't really know as I haven't done any sharpening on either the Float Glass or a Surface Plate - flying blind here! ? I did do a little messing around with both planes on the Red Oak I got. With the help of my SIL, we got it into the schoolhouse but it wasn't stickered (the sawmill said I could have some stickers but I forgot to grab any). It was raining when we brought them in and they were soaked. I didn't have enough of anything to make stickers from so I thought it best I stack them vertically. But, with these five 3 foot x 5 foot windows there was a risk of them falling over and crashing through one of them so I made some side supports out of scrap 2x4s I did have to prevent them from falling over, hopefully. ***most of them don't have square cuts on their ends - not sure why*** So, as I said I would, I pulled one down the other night and hit it with both planes. While they both performed as expected - they did shave the wood - my setup is wanting. I think I like the action of the Gage plane (it seemed to run smoother of the wood) but, the #7, even with its chipped mouth, I think cut a little better. The area wanting is the work surface. I knew going in that I wasn't set up for hand planing wood and, as expected, I pushed the Bora Centipede around quite a bit ?. And, this Centipede is too damn short for me. It killed my back after just a few minutes. It did reaffirm my need to go get my Delta 22-650 Thickness Planer - will try after the 1st. I was able to support (stop) the wood along its length with @benchdogs.co.uk Bench Top Protectors intended for other work. I clamped the far end to the Festool-ish Multi-Function Slab. But, I either need a "work bench" (and, YES, I certainly do and plan to) of some sort OR a wall in closes proximity to the work piece. As a side note and a discovery, Bora has come out with a Centipede that's 36 inches tall now. It came out in October, after I bought mine (which was never intended to use for what I'm using it for ?. Thanks for the assist, again, T! I want you to know it is greatly appreciated! Regards, RR

-

A post- L-Tryptophan Thanksgiving to you all! ? I hope you all had a melodious affair! Regards, RR

-

HI T, No, I was injured/reserved yesterday after doing what I tried and failed at posting the other day then purchasing and retrieving and helping to unload a bunch of Red Oak (estimated at 150bf) into the Schoolhouse. Not sure when I'm going to get the sole right. I'd like to have it machined but since I mentioned that I thought I'd try to sand it parallel to the carriage (flat surface sanding, not hand or hand-held machine sanding). IF I were to try to sand it flat and parallel to the carriage and failed I could have it machined after that. Also, that Red Oak I picked up is rough sawn. I might try playing around with it and that Gage plane and my #7 with the chipped mouth. ***btw, I went to the sawmill thinking I was buying White Oak. Red Oak was on top of mixed stacks. Did not realize until I got it all back here that it will require acrylic solid stain to prepare it for use as fascia board, or for any exterior use that is*** ?, RR

-

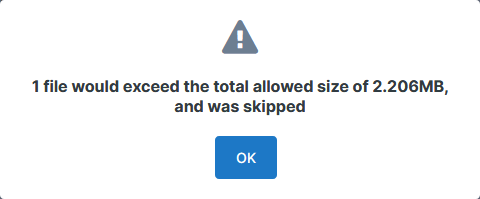

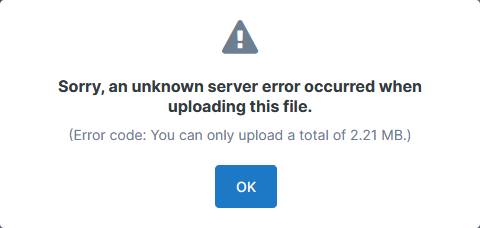

Hi T, I dragged and dropped three images into the post. I tried to drag and drop a forth image and it gave me a different pop-up now. I think I did what you suggested. I dragged and dropped images to the limit then deleted the image in the body of the post which leaves the images in the "Uploaded Images" box at the bottom. Or am I doing that backwards from what you suggest? I should leave the images in the body of the post and delete from the "Uploaded..." box? P.S. Btw, I didn't have any problems post my other multiple image posts. Only tonight did it happen. Regards, RR

-

Hey BW. I did try to upload multiple images back to back very quickly, yes. When that errored out I deleted all the previously uploaded images and tried again one by one with the "choose files". That errored out, too. I deleted all those previously uploaded images again and tried to drag and drop them in. That errored out, too. No matter what I tried it wouldn't load beyond 3 images. It errored out on the 4th image every time. Tips?, RR

-

Scratch keeping the sole square to the sides! With the brass repair plates I can't get a good read on where the sides are in relation to the sole. Some spots are relatively square but, in one spot it looks like about 1/8" out of square ?! Getting the sole flat and parallel to the carriage is the new goal! ?? Just can't ever use it on a shooting board or like operation. Right now, as best as I can set it up, the carriage to the sole is flush on the left side of the carriage and .010 protruding on the right side. (measured with a 6" machinist square resting on the sole and my dial caliper aligned on the blade of the square while touching off on the protrusion) ?, RR

-

Hi T ?! Nice website! Very informative. Thank you, T! I will check it out better when I get a minute. I really do appreciate the assist! I'm trying to finish painting my window insulation trim (I have one side of the four remaining, then install them), so I can move to the next necessary utilitarian, not really woodworking project (2x4Basics shelf and bench (bench for temporary kitchen counter space)). *I just spent $148usd last night on 16 "select" 2x4s and three 1/2 (2' x 8') sheets of 1/2" plywood - WOW!* I have a machining background and am aware of maintaining square while flattening an adjacent surface. I'm not equipped to machine it so ever since I posted that the "carriage" (A much better term to refer to it!) I've been letting the potential solutions roll around in the massive Thought Process Machine on my shoulders and still waiting for it to reach a best solution - my own solution or that of another individual! ?. I know I have to flatten the sole and get it parallel to the carriage while maintaining square with both sides. I'm pondering bringing it to a machine shop and see if they can square it up for me. If I had a mill, or even a decent drill press with a cross slide vise, I'd do it myself. As for the chip breaker, it is out of the users control. It's built in. Much like a small block plane it locks in to a roll pin set into the frame of the plane. I only mentioned the .004 shaving because it was my first cut off it after touching the iron to the wood to cut anything, I wasn't trying for any particular thickness. Bring it! ?? Thanks a bunch, again, for the information T....really appreciate it! ?, RR

-

Axiom Stratus Air Cleaner/Air Filtration....

RxR Sawdust Station replied to RxR Sawdust Station's topic in Power Tools

That crazy, I am...to want it, but then justifying it is a matter altogether different! ? I'd have to literally build a shop just to put it in - but I'd do it! ? I think it was Stumpy talking about him seeing it at a woodworking convention a year or so ago and the fellow standing right next to the machine talking to the Harvey representative in the booth asked if the Harvey rep could turn it on. The representative said "It is on". Granted, it was on low, but still....amazing machine! Stumpy has one in his new shop. ?, RR -

Axiom Stratus Air Cleaner/Air Filtration....

RxR Sawdust Station replied to RxR Sawdust Station's topic in Power Tools

Yeah, I was rather stunned when I saw the price, too. It better be able to cook breakfast at that price! ? The Rikon unit does look good! The WEN unit, the 3415T, the more capable of the two they offer looks good, too. And at $293.93 it's nearly half of what the other similar units go for. I include WEN because I see them supporting Woodworkers of all types on IG, they've even liked some of my posts. RR -

Axiom Stratus Air Cleaner/Air Filtration....

RxR Sawdust Station replied to RxR Sawdust Station's topic in Power Tools

Ah...so what English speaking people call Jury-rigged (something assembled quickly with the materials on hand) or Jerry-rigged (cheaply or poorly built)! ? **just pulling your leg, Jack!** ? Thanks, T, sincerely!...that's a new one for me. RR -

A Coffee Table / Sofa Table Set

RxR Sawdust Station replied to Bushwacked's topic in Member Project Journals

Nice! I like the visual interest created by the staggered layers, the staggered open spaces. Well done! Nice eye, Moms! ?, RR -

Axiom Stratus Air Cleaner/Air Filtration....

RxR Sawdust Station replied to RxR Sawdust Station's topic in Power Tools

Hello T! You'll have to excuse me but, what is "jack leg air filtration"? I have pondered doing the same. I may still do it as I do hope to try spray finishing one day (I'll have some questions on that topic when the time comes! ?). I saw DIY Tyler's spray filter and thought I'd do that IF I ever needed to. I like your way of thinking. When I first started back into woodworking I called what I was doing as the "Do With What You Got Shop" ? I am trying to work a consumer purchased product into the Schoolhouse Woodshop but, who knows what the future holds. I may come across some free box fans and some scrap plywood and put something together! Anything can happen at any time! ? Thanks for your input, T! It is greatly appreciated! ?, RR -

Axiom Stratus Air Cleaner/Air Filtration....

RxR Sawdust Station replied to RxR Sawdust Station's topic in Power Tools

I'm with ya there, brother! I have seriously considered that option. Just the other day I saw a great blower with motor on Facebook. It looked brand new for $50 (I always think that's a starting price and I can negotiate it down even just a little) and I instantly thought of Jay Bate's DIY air filtration unit. Thanks a bunch, Jamie! I appreciate your thoughts on the subject! ?, RR -

Axiom Stratus Air Cleaner/Air Filtration....

RxR Sawdust Station replied to RxR Sawdust Station's topic in Power Tools

Thank you, BW! I like Marc's approach to air filtration in that video. I, too, am pretty isolated here - far away from any other residences - far fewer than what he described. The nearest dwellings besides my brother's place is at least a 1/4 mile away from the Schoolhouse. After watching Marc's video I'm thinking I'm going to direct my dust collection outside. Before this, when I thought I was going to use the two stage system I built I was going to use the collection barrel but outside and I was thinking about buying the Oneida Dust Sentry ($148). Thanks for jogging my memory on the outdoors dump! And, yeah on the Bates video. I've been following his work for a very long time. When I jumped to the video on YT from your link I saw I had already ?'d it ?. He puts out great content, to include this video. Thank you for your input, BW! I do appreciate it! ?, RR