Every purchase made through our Amazon Affiliate Page helps support this site

-

Posts

1,430 -

Joined

-

Last visited

-

Days Won

26

Content Type

Profiles

Forums

Downloads

Gallery

Events

Store

Articles

Blogs

Posts posted by Tmize

-

-

Just a FYI for everyone LV order online process is slammed. I order about 6-7 items from them back on the 7th an are still processing the order do to the super high volume. I thought it was odd I had got an email yet with tracking. So I called customer service an as normal they were great. I guess them doing free shipping on every item an the short staff a regulation they are having trouble fulfilling orders. It’s a good problem to have right now in retail. Any other major suppliers backed log to? I know Lie-Nielsen is sold out at about every store that carries them.

-

1

1

-

-

I never read the show notes either unless they mention a link in the video that interest me

-

I may have seen it an just forgot in one of your videos. What all do you keep in all those drawers at the table saw. I can see blades,wrench’s, fingerboard,miter gauge. What else would be there that would fit in the drawers?

-

That is one of the many table saw jigs I’ve been planning on build for years.

-

Looks like it will serve its purpose well

-

Back to woodworking ?. When I built ours I did twin 1/2 tenons in the top an bottom. It hasn’t fell apart yet. I was closer to 2” thick on my legs tho. 1/4” gap between 1/4” on each side

-

1

1

-

-

Just he them send you the 17” this time for the trouble ?

-

Hcm

in Power Tools

He review is what drew me to the rikon. What made the decision is the xy table being able to clamp it one time an work the mortise down the board. That should eliminate show human error out of it.

-

Hcm

in Power Tools

1 hour ago, Chet said:Two real important words to keep in mind regarding the shop.

I don't know if you ordered the same model as Kev but there is a review he did of his in the review section. I don't recall if he covered out feed. On thing to remember is that if you need out feed support, you need it on both sides. You want to be able to slide your work to the other end to do the other mortise like in a frame and panel. If you flip you work end for end you can end up not having the two mortises centered and even if it is off by just a few thou, by the time you do this at four corners you can end up with a pretty wonky frame and panel.

That is a good point on always reference from the same side against the fence

-

1

1

-

-

Hcm

in Power Tools

So I bought a rikon hollow chisel mortiser last week now I’m waiting for it to be delivered. I’m covered up in yard work lately so haven’t made it down to the shop to figure out some things placement wise. So how much outfeed support do I need with this machine. I’m sure if I was doing bed rails that is another story. I do a fair mount of frame an panel construction. I finally got tired of pounding out mortises.

I’m in the middle of a ever evolving shop remodel now

-

15 minutes ago, Jamie said:

Courtney did say that it makes her no difference if there are breadboard ends on it or not. My thoughts are hey that would make it a lot easier, but if I’m going to sit at this table the rest of my life am I gonna be happy knowing I coulda done more?

Wife tells my that all the time. I tend to always go over board. She could care less about dovetails or any of the other joinery that I take pride in as a builder. What I enjoy as I walk thru our home an see the pieces I’ve made I see those details an appreciate them. Even if she want everything painted?

-

The last bread board end I did I didn’t pin it at all. What I did was do a tongue an groove joint but concaved the center about 1/16” glued the center 1/3 an clamped basically a spring joint. Last time I was a my dads it’s held up well. It was only about 18” wide not 40”.

-

1

1

-

-

I like the table. I don’t know if I have ever seen tusked tenons done like that definitely a focal point on the table.

To me making your own loose tenons joints. The tough part is mortiseing into the end grain is tough. I guess with a dual guide router would be the best.

-

I rarely ever go below 400 grit. Most of the time I start at my 1200 grit diamond and that usually tells me if I’m good or need to go down.

-

I agree not a expert tho just play one on the internet ?

-

1

1

-

2

2

-

-

That’s a good idea sure I could get the template somewhere

-

1

1

-

-

Yea they still want about $400 for them. I got a couple more tools I’m wanting to buy instead of spending it on one vise. I can always upgrade if I feel I need to.

-

-

2 minutes ago, Kev said:

Ah, gotchya.. I think Jay Bates just used a block of wood on the floor and it seemed to work fine for him..

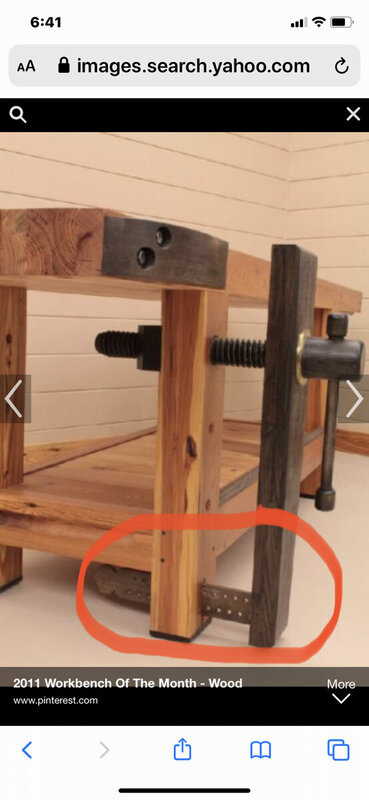

Yes that is where I seen that. The traditional way I believe is a board mortised thru the leg with multiple holes in it an move a pin to the desired offset to have the vise toe in just a little bit

-

-

Yea I’m not doing the sliding deadman either I’m trying to upload a pic of it. It’s not shown on it either. What I’m talking about is the old way of adjusting the toe in on the vise without the crisscross that bench craft makes with theirs

3 minutes ago, Kev said:I don't have the deadman in mine and I'm not sure I ever really missed it.. One thing I did to is to locate the hold fast storage holes in the other leg in a place that they can be used if/when needed to hold long material. I hope that makes sense?

-

Well I’ve come back to the classic Roubo design by bench crafted. I don’t think I can spring for their leg vise hardware this time. I am going to do Lee valley tail vise screw for the leg vise. I have that vise now as a tail vise on my bench now an it is very smooth an operate great so I don’t think I’ll have much problems with it in the leg vise. I don’t know yet if I’ll do the sliding board with pins or just use a wedge at the bottom to counter the racking suggestions?

-

I sketch everything out on graph paper. I determine a scale for the grid a an work dimensions off that

-

1

1

-

-

I would make the doors next. Like you said you can adjust the pull outs easier

-

1

1

-

Lee valley

in General Discussion

Posted

They said they was running 7-10 days behind before ready to ship